Production method for sensitivity enhanced extrinsic F-P optical fiber temperature sensor

An optical fiber temperature and manufacturing method technology, applied in the field of sensors, can solve the problems of difficult sensors, slow temperature response, slow temperature response, etc., and achieve the effects of high temperature sensitivity, good fiber end face, and fast temperature response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

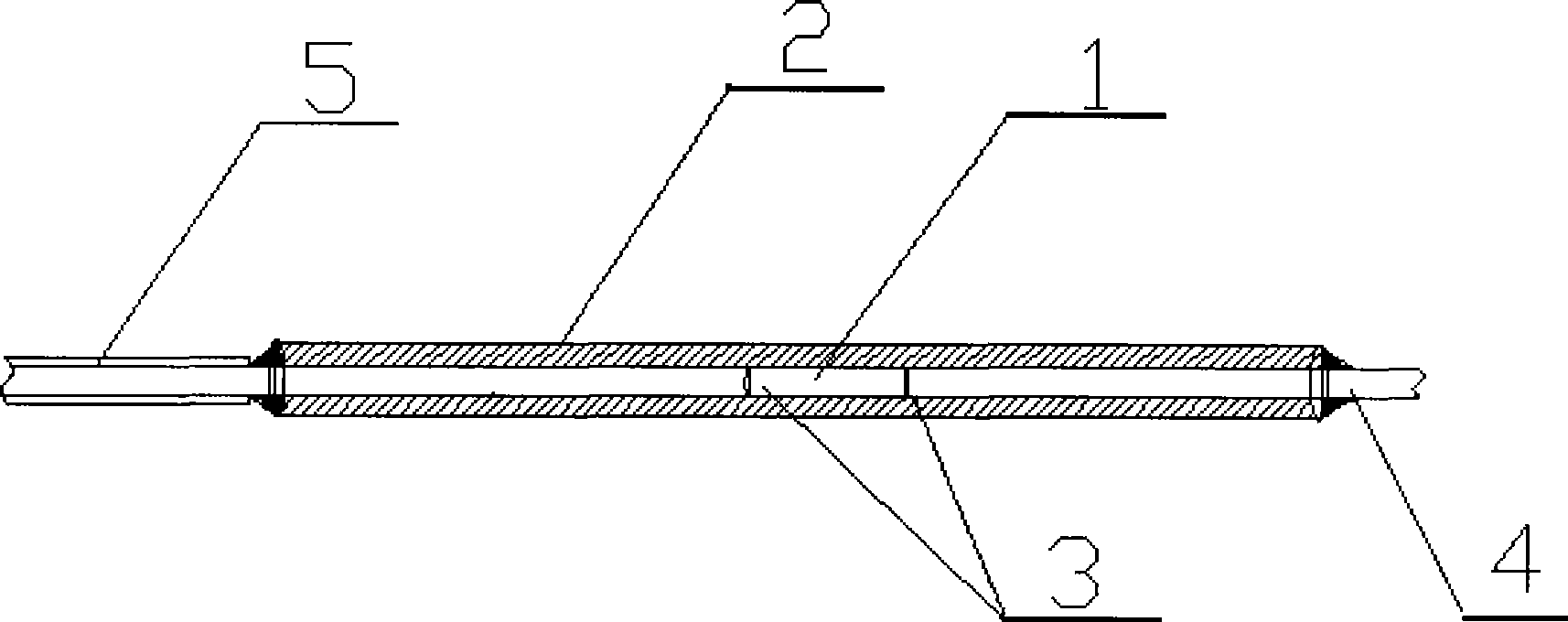

[0013] An aluminum metal capillary with an inner diameter of 0.13 mm and an outer diameter of 2 mm is placed in an ultrasonic bath filled with alcohol for cleaning and drying. Remove the coating layer at one end of the optical fiber. The bare optical fiber 4 is 5 to 10 mm longer than the aluminum metal capillary. Use acetone to clean the surface of the bare optical fiber 4. Then put the bare optical fiber 4 on the frame of the optical fiber cutter. The pinch plate on the side pushes the blade, which can form a score on the surface of the optical fiber, but the optical fiber cannot be interrupted during the operation. Insert the bare optical fiber 4 with a notch defect into the aluminum metal capillary 2, adjust the position of the notch defect in the aluminum metal capillary 2, and then use epoxy resin adhesive to connect the free end of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com