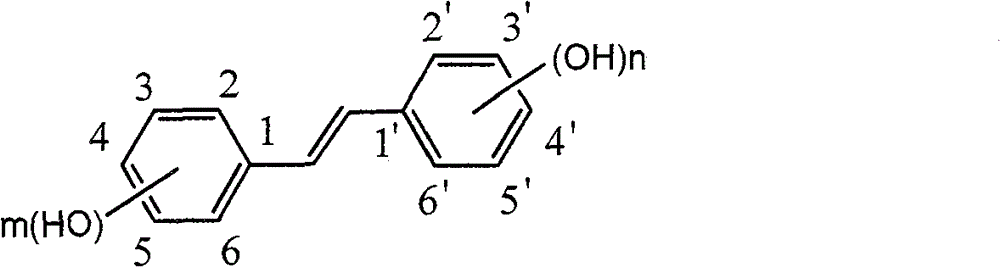

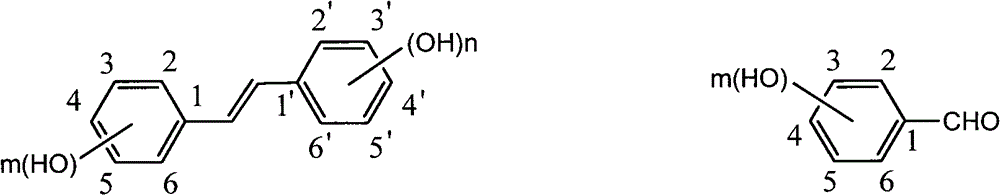

Preparation of trans-polyhydroxy diphenyl ethylene

The technology of polyhydroxy stilbene and diphenyl acrylic acid is applied in the chemical field, and can solve the problems of hydroxyl group protection and deprotection, low reaction selectivity, high difficulty in industrialization and the like, and achieves low cost, good atom economy, Easy to purify effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

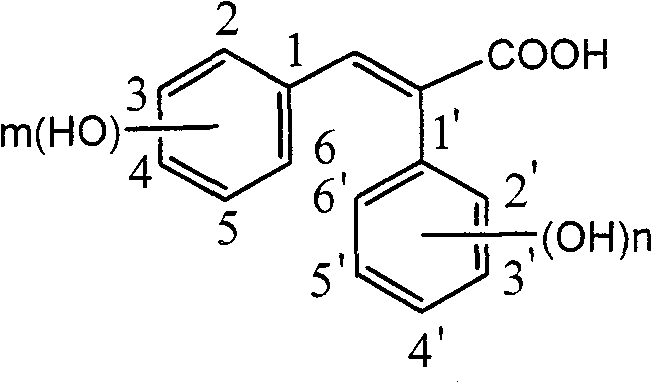

Embodiment 1

[0025] Weigh 3.04g (0.02mol) of 4-hydroxyphenylacetic acid, add 2.76g (0.02mol) of 3,5-dihydroxybenzaldehyde into the reaction flask, dissolve with 12.24g (0.12mol) of acetic anhydride, then add 5.05g (0.05 mol) triethylamine, heated to 110°C, reacted for 6 hours, poured into ice water to precipitate solid, dissolved with 10% sodium hydroxide, washed with ethyl acetate, and crystallized at low temperature after acidifying the water layer to obtain a light yellow solid (E )-2-(4'-hydroxyphenyl)-3-(3',5'-dihydroxyphenyl)-acrylic acid, weighed dry to obtain 4.98g, yield 91.5%, recrystallized with ethanol-water to obtain 4.45 g white crystals, yield 81.8%.

Embodiment 2

[0027] Weigh 4.52g (0.02mol) of 4-hydroxyphenylacetic acid, add 2.21g (0.016mol) of 3,5-dihydroxybenzaldehyde into the reaction flask, dissolve with 8.16g (0.08mol) acetic anhydride, then add 2.02g (0.02 mol) triethylamine, heated to 100°C, reacted for 8 hours, poured into ice water to precipitate solid, dissolved with 10% sodium hydroxide, washed with ethyl acetate, and crystallized at low temperature after acidifying the water layer to obtain a light yellow solid (E )-2-(4'-hydroxyphenyl)-3-(3',5'-dihydroxyphenyl)-acrylic acid, weighed dry to obtain 3.75g, yield 86.2%, recrystallized with methanol-water to obtain 3.11 g pale yellow crystals, yield 71.5%.

Embodiment 3

[0029] Weigh 4.52g (0.02mol) of 4-hydroxyphenylacetic acid, add 3.31g (0.024mol) of 3,5-dihydroxybenzaldehyde into the reaction flask, dissolve with 16.32g (0.16mol) of acetic anhydride, then add 8.08g (0.08 mol) triethylamine, heated to 140°C, reacted for 2 hours, poured into ice water to precipitate solid, dissolved with 10% sodium hydroxide, washed with ethyl acetate, and crystallized at low temperature after acidifying the water layer to obtain a light yellow solid (E )-2-(4'-hydroxyphenyl)-3-(3',5'-dihydroxyphenyl)-acrylic acid, dry and weighed to obtain 4.82g, yield 88.6%, weighted by ethyl acetate-petroleum ether Crystallization gave 4.31 g of light yellow crystals, with a yield of 79.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com