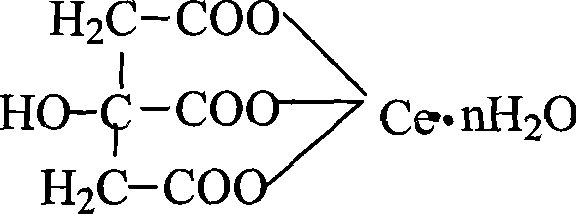

Cerium citrate nontoxic rust-preventive pigment and coating thereof

A technology of cerium citrate and anti-rust pigments, applied in coatings, anti-corrosion coatings, azo dyes, etc., can solve the problems of deep color, increase the difficulty of dispersion, and affect the rapid promotion and use, and achieve good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Dissolve 0.1mol cerium nitrate in 100ml distilled water to prepare solution A; dissolve 0.1mol sodium citrate in 100ml distilled water to prepare solution B, drop solution A into solution B, mix and stir for 1 hour, adjust with 2mol / L nitric acid The pH value is 3.5, after 6 hours of aging, filtration, washing, vacuum drying at 60°C, crushing and packaging to obtain cerium citrate. According to the vario EL III type elemental analyzer (Germany), the percentage content of carbon element is 19.1%, the percentage content of hydrogen element is 2.8315%, and the purity of cerium citrate is calculated to be 99.4%. The oil absorption (OA) of cerium citrate measured according to the method of GB5211.15-88 is 68ml / g, the specific gravity (d) of the pigment measured according to GB1713-79 is 2.1, pH=6.

example 2

[0041] Dissolve 0.1mol cerium chloride in 100ml distilled water to prepare solution A; dissolve 0.12mol potassium citrate in 100ml distilled water to prepare solution B, drop solution A into solution B, mix and stir for 2 hours, and dilute with 2mol / L Adjust the pH value to 4 with hydrochloric acid, age for 7 hours, filter, wash, vacuum dry at 80°C, crush and pack to obtain cerium citrate. Through vario EL III type elemental analyzer (Germany), the percentage content of carbon element is 19.2%, the percentage content of hydrogen element is 2.766%, and the purity of cerium citrate is calculated to be 99.3%. According to the method of GB5211.15-88, the oil absorption (OA) of cerium citrate is 70ml / g, and the specific gravity (d) of the pigment is 2.2 according to GB1713-79, pH=7.

example 3

[0043] Dissolve 0.05mol cerium sulfate in 100ml distilled water to prepare solution A; dissolve 0.13mol ammonium citrate in 100ml distilled water to prepare solution B, drop solution A into solution B, mix and stir for 1.5 hours, and use 1mol / L dilute sulfuric acid Adjust the pH value to 4.5, age for 8 hours, filter, wash, vacuum dry at 70°C, crush and pack to obtain cerium citrate. According to the vario EL III elemental analyzer (Germany), the percentage content of carbon element is 19.0%, the percentage content of hydrogen element is 2.897%, and the purity of cerium citrate is calculated to be 99.2%. The oil absorption (OA) of cerium citrate measured according to the method of GB5211.15-88 is 65ml / g, the specific gravity (d) of the pigment measured according to GB1713-79 is 2, and pH=6.5.

[0044] 2 Preparation of anti-corrosion coating

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com