Beta-mannanase for feeding and preparation thereof

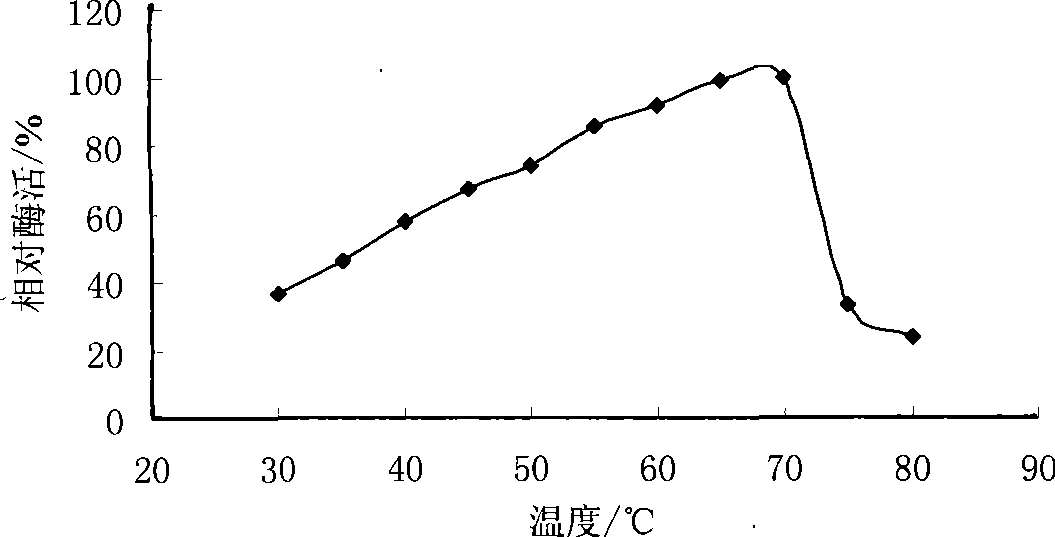

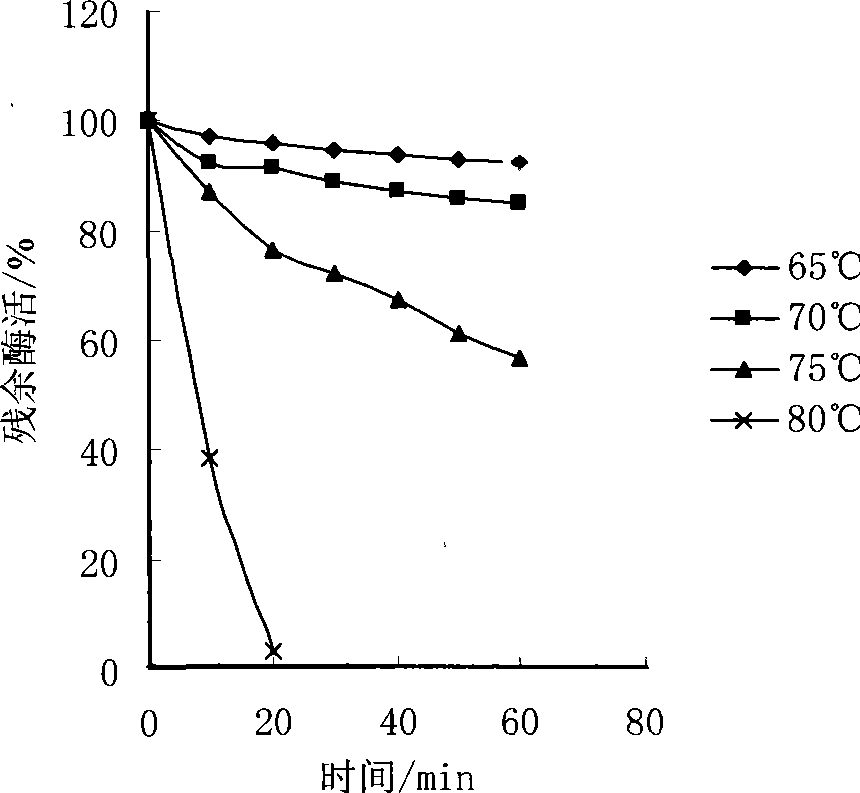

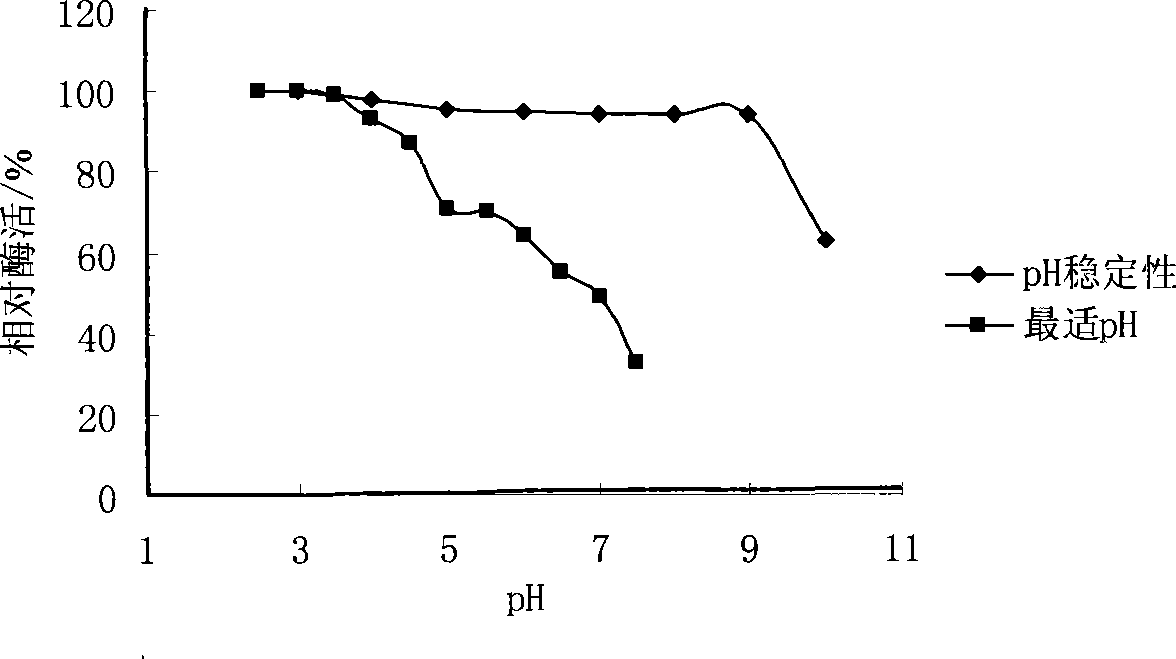

A technology of mannanase and feeding, which is applied in the field of microbial fermentation and enzyme engineering, can solve the problems of low thermal stability and pH stability, and achieve the effect of low production cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: (beta-mannanase production and preparation 1)

[0039] In this example, β-mannanase was prepared according to the following steps:

[0040] (1) Preparation of media of various levels of Aspergillus niger strain MA-56: including,

[0041] ① Inclined seed medium: peeled potato 200g / l, sucrose 20g / l, agar 20g / l, natural pH, sterilized by 0.1Mpa for 20min;

[0042] ②Solid seed culture medium: put 10g of culture medium prepared by bran, soybean meal and konjac powder in a ratio of 80:19:1 in weight into a 300ml triangular flask, add tap water in a ratio of 1:1 to the weight of solid matter, and stir Evenly, sterilized by 0.1Mpa for 30min;

[0043] ③Solid production medium: First, prepare a solid medium by bran, soybean meal and konjac flour in a ratio of 75:23:3 by weight; then add water to the solid medium and water in a ratio of 1:1.3 by weight and stir evenly In a cloth bag, sterilize at 0.1Mpa for 30min, after cooling, put it evenly in a curved plate, an...

Embodiment 2

[0048] Embodiment 2: (beta-mannanase production preparation 2)

[0049] In this example: the preparation of step (1) aspergillus niger strain MA-56 culture medium at all levels: 3. solid production medium: first bran, soybean meal and konjac flour are formulated into solid medium by weight 88:13:1 ratio ; Then add water to the solid medium and water according to the ratio of 1:1.1 by weight, stir evenly, put it into a cloth bag, sterilize it at 0.1Mpa for 30min, and place it evenly in a curved plate after cooling, the thickness of the fermented material is 2-3cm;

[0050] Step (4) xylanase fermentation production: mix the solid seed spore suspension in step (3) with the solid production medium in step (1)③ in a ratio of 15:100 in parts by weight, and put it in a koji room at 28°C for fermentation and culture 56h to obtain β-mannanase enzyme koji for feeding;

[0051] Step (5): through the detection of β-mannanase activity for feed, it reaches 1×10 5 ~1.3×10 5 U / g;

[0052]...

Embodiment 3

[0053] Embodiment 3: (beta-mannanase production preparation 3)

[0054] In this example: step (1) preparation of various levels of medium for Aspergillus niger strain MA-56: ③ solid production medium: first prepare solid medium by bran, soybean meal and konjac flour in a ratio of 62:37:6 by weight ; Then add water to the solid medium and water according to the weight ratio of 1:0.9, stir evenly, put it into a cloth bag, sterilize it at 0.1Mpa for 30min, and place it evenly in a curved plate after cooling, the thickness of the fermented material is 2-3cm;

[0055] Step (4) xylanase fermentation production: mix the solid seed spore suspension in step (3) with the solid production medium in step (1)③ in a ratio of 30:100 in parts by weight, and place it in a koji room at 28°C for fermentation and culture 56h to obtain β-mannanase enzyme koji for feeding;

[0056] Step (5): through the detection of β-mannanase activity for feed, it reaches 1×10 5 ~1.3×10 5 U / g;

[0057] All th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com