Magnetic control cathode assembly for cleaning one-dimensional linear plasma with high efficiency

A plasma and magnetron cathode technology, applied in cleaning methods and appliances, semiconductor/solid-state device manufacturing, discharge tubes, etc., can solve the problems of low plasma etching/cleaning rate, non-adjustable plasma density, and Low-level problems, achieve high-uniformity surface cleaning treatment, save equipment internal space, and achieve high plasma density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

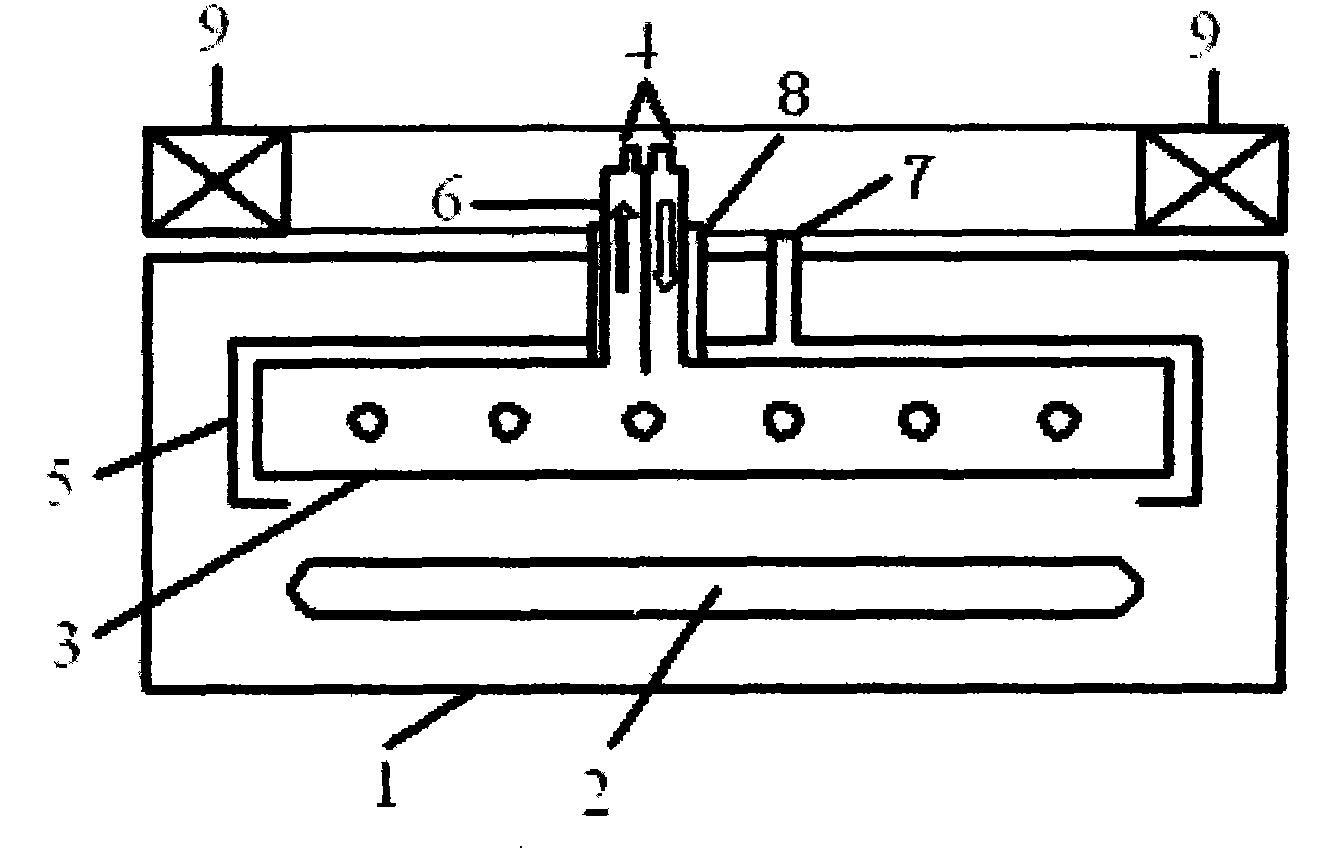

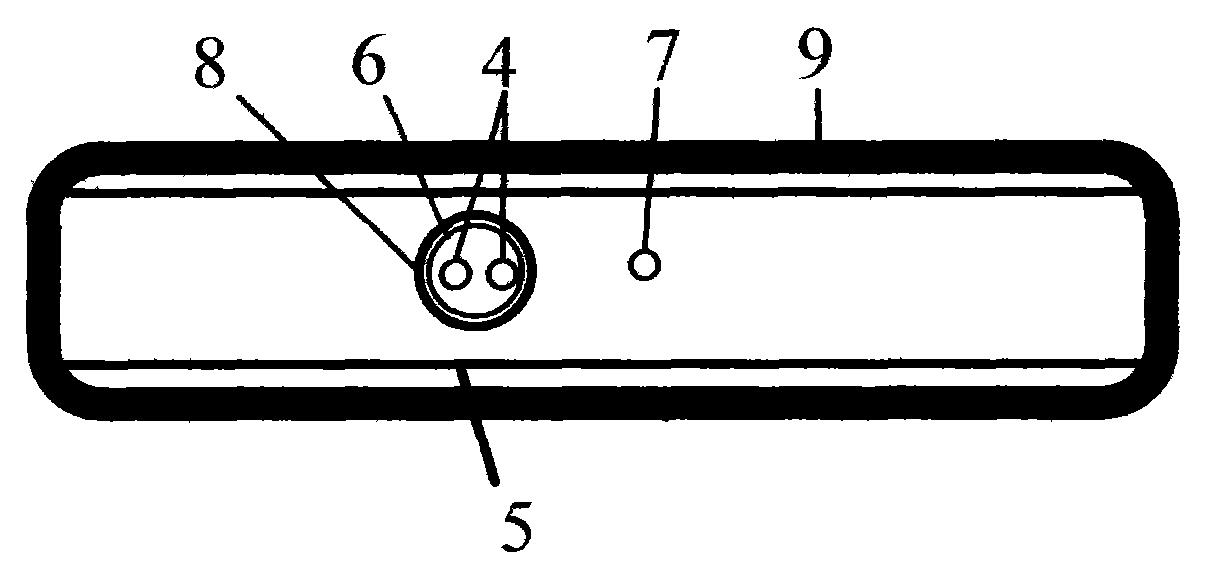

[0018] By adopting the cathode device of the present invention, the processing object 2, such as large-area glass, can be continuously cleaned under atmospheric pressure. The width of the glass is 1.5m, and the length of the linear metal plate cathode 3 is 1.8m, and the width is 50mm. , the distance between the large-area glass and the linear metal plate cathode 3 is 5 mm, and the glass is placed directly under the linear metal cathode plate 3 through the transmission device, and performs a uniform linear reciprocating motion. The cavity maintains an air atmosphere of 1 atmosphere, and the power supply passes through The cathode electrode joint 6 generates plasma on the surface of the linear metal plate cathode 3, and the intensity of the plasma is adjusted by adjusting the power of the cathode power supply.

[0019] The uniformity of this method is about 85% to the cleaning of large-area glass. On the basis of the above-mentioned technology, an electric current is added on the...

Embodiment 2

[0021] Adopt the magnetic field negative electrode of the present invention to process object 2 under atmospheric pressure: large-area polymer film, as the cleaning treatment of plastic film surface, glass continuous cleaning, the width of large-area polymer film is 1m, and the length of linear metal plate cathode 3 is 1.2m, the width is 80mm, the distance between the large-area glass and the linear metal plate cathode 3 is 8mm, the glass is placed directly under the linear metal plate cathode 3 through the transmission device, and moves at a uniform speed in one direction, and passes through the intake pipe 7 in the vacuum chamber Argon gas is introduced into the body to keep the air pressure in the cavity at 0.8 Pa. The power supply generates plasma on the surface of the linear metal plate cathode 3 exposed outside the shielding cover 5 through the cathode electrode connector 6, and the plasma intensity is adjusted by adjusting the power of the cathode power supply. The unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com