Hedyotis diffusa Willd. extract and method for separating and preparing the same

A technology for extracting Hedyotis diffusa, which is applied in the field of separation and preparation of Hedyotis diffusa extract, can solve the problems of inability to produce on a large scale, outdated detection methods, and low degree of automation, etc., and is suitable for large-scale industrial production, Small organic solvent residue and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

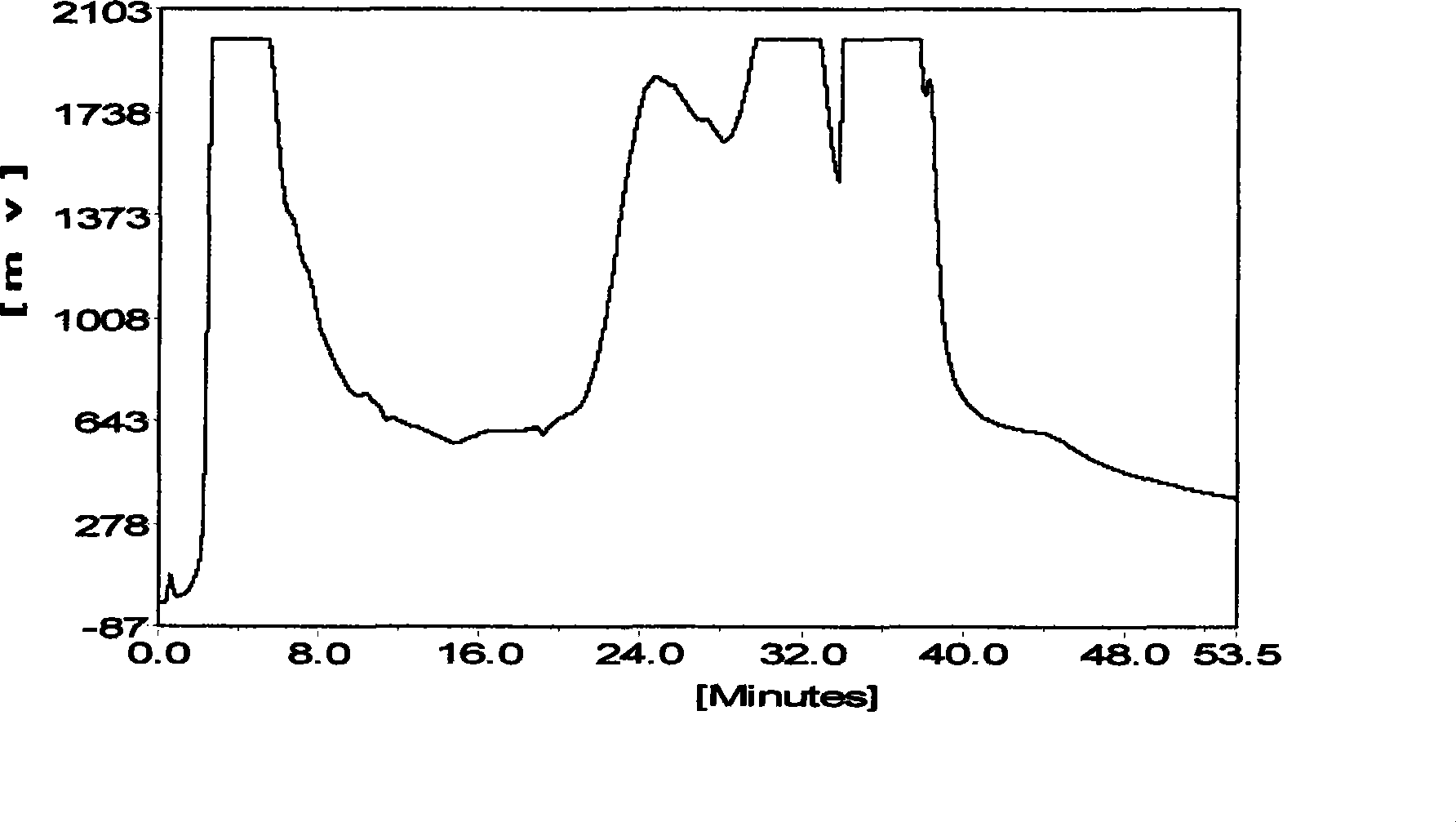

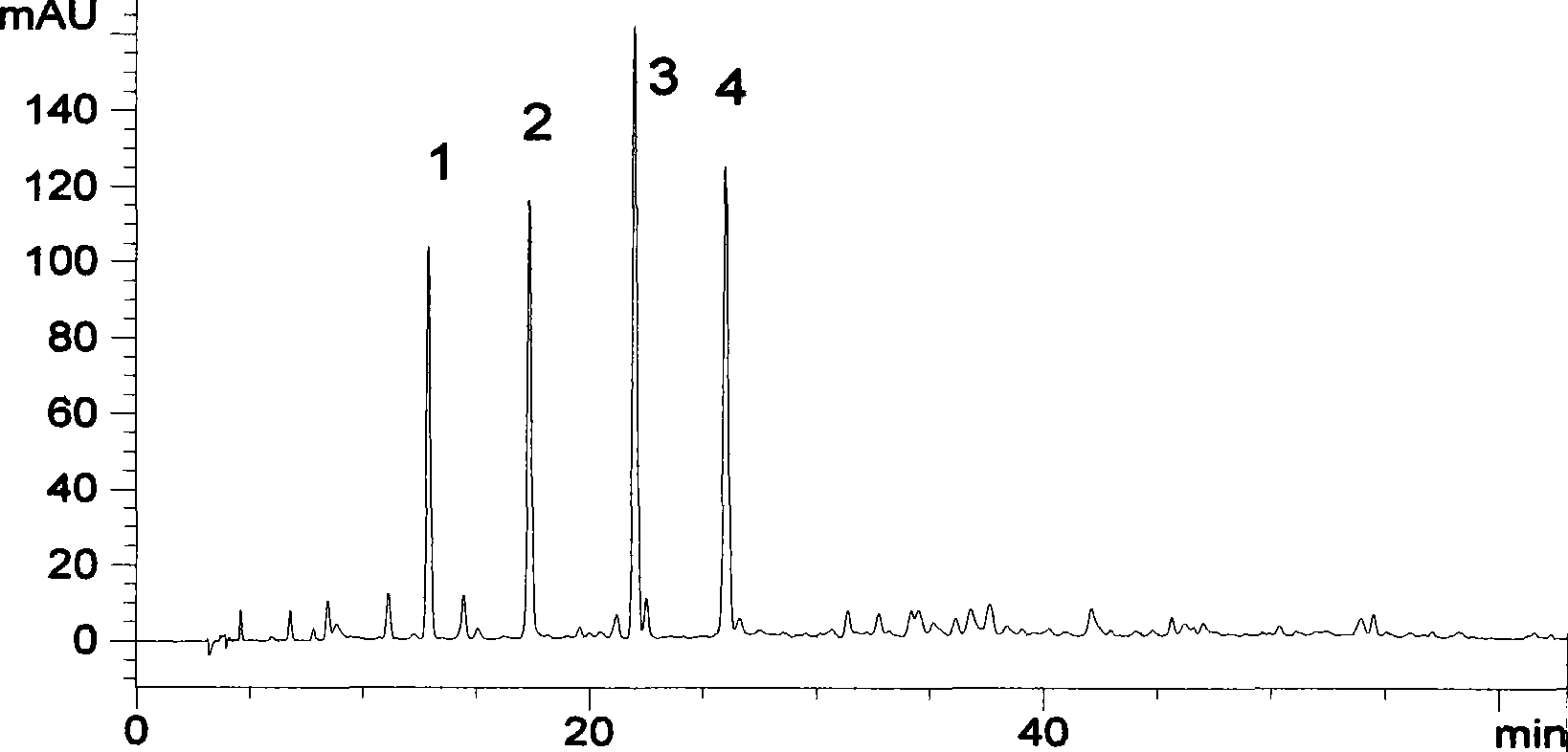

[0025] Grind the medicinal material of Hedyotis diffusa, weigh 2 kg quantitatively, put it in a 20-liter extraction tank, add 20 liters of water to decoct for 1 hour, filter, and save the filtrate for later use, add 20 liters of water to the filter residue and decoct for 1 hour, filter, and the filtrate Combined with the first time, the filter residue was discarded. The extract was concentrated by rotary evaporation to 500 ml to obtain the water extract fraction of Hedyotis diffusa. Add 710 milliliters of 95% ethanol to the concentrated solution, stir well, let stand at room temperature for 24 hours, filter, discard the filter residue, concentrate the filtrate to 300 milliliters, add 1600 milliliters of 95% ethanol to the concentrated solution, stir well, and let stand at room temperature for 24 hours hour, filtered, and the filter residue was discarded, the filtrate was concentrated until it had no alcohol smell, and the concentrated solution was centrifuged in a high-speed c...

Embodiment 2

[0031] Grind the medicinal material of Hedyotis diffusa, weigh 5 kg quantitatively, put it in a 100-liter extraction tank, add 40 liters of water to decoct for 2 hours, filter, and save the filtrate for later use, add 40 liters of water to the filter residue and decoct for 2 hours, filter, and the filtrate Combined with the first time, the filter residue was discarded. The extract was concentrated by rotary evaporation to 1000 ml to obtain the water extract fraction of Hedyotis diffusa. Add 1710 milliliters of 95% ethanol to the concentrated solution, stir well, let stand at room temperature for 24 hours, filter, discard the filter residue, concentrate the filtrate to 500 milliliters, add 2670 milliliters of 95% ethanol to the concentrated solution, stir well, and let stand at room temperature for 24 hours hour, filtered, and the filter residue was discarded, the filtrate was concentrated until it had no alcohol smell, and the concentrated solution was centrifuged in a high-sp...

Embodiment 3

[0035] Grind the medicinal material of Hedyotis diffusa, weigh 10 kg quantitatively, put it in a 100-liter extraction tank, add 60 liters of water to decoct for 3 hours, filter, and save the filtrate for later use, add 60 liters of water to the filter residue and decoct for 3 hours, filter, and the filtrate Combined with the first time, the filter residue was discarded. The extract was concentrated by rotary evaporation to 2000 ml to obtain the water extract fraction of Hedyotis diffusa. Add 3420 milliliters of 95% ethanol to the concentrated solution, stir well, let stand at room temperature for 24 hours, filter, discard the filter residue, concentrate the filtrate to 1500 milliliters, add 8000 milliliters of 95% ethanol to the concentrated solution, stir well, and let stand at room temperature for 24 hours hour, filtered, and the filter residue was discarded, the filtrate was concentrated until it had no alcohol smell, and the concentrated solution was centrifuged in a high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com