Method for producing tert-butylamine based on coupling reaction-separation

A technology of tert-butylamine and reaction, applied in the production field of organic compound tert-butylamine, can solve the problems of incapability of large-scale adoption, potential safety hazard and high reaction pressure, and achieve the effects of easy control of reaction conditions, convenient operation and good product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

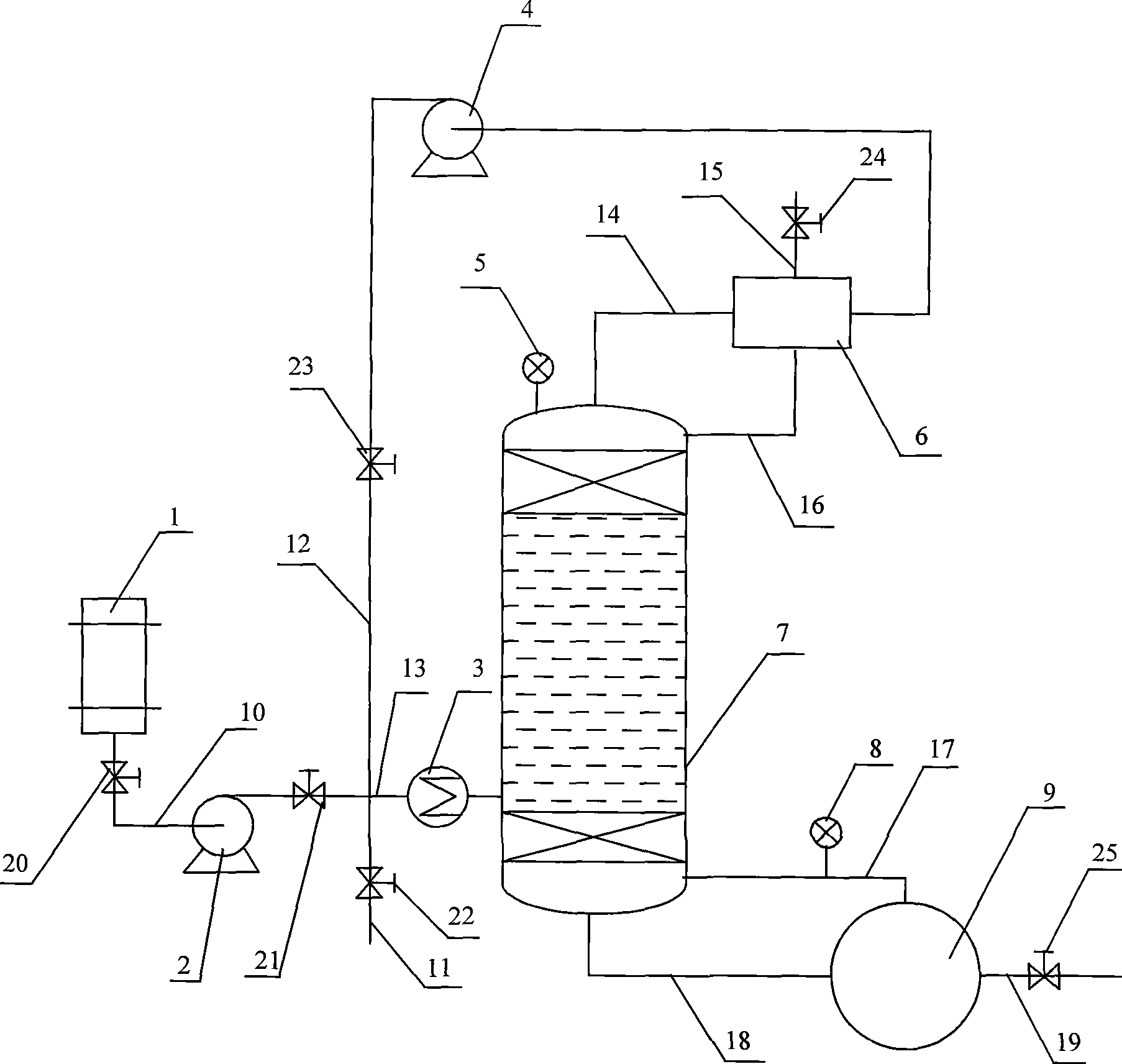

[0035] Embodiment 1, figure 1 A circulating pressurized reaction-rectification coupling device is given, including a raw material tank 1, a feed pump 2, a condenser 6, a reactive distillation column 7, a reboiler 9, and the like.

[0036] The raw material tank 1 communicates with the inlet of the collecting pipe 13 through the feed pipe 10, and the feed pipe 10 is provided with a stop valve 20, a feed pump 2 and a stop valve 21 in sequence according to the flow direction of the feed liquid; the purge gas pipe 11 It communicates with the inlet of the collecting pipe 13 , and a cut-off valve 22 is provided on the purge gas pipe 11 .

[0037] The reactive distillation tower 7 is a packed tower, the middle part of which is loaded with a loaded catalyst, and a material inlet is arranged in the middle part of the reactive distillation tower 7, and the material inlet is connected with the outlet of the collecting pipe 13. A preheater 3 is provided on the collecting pipe 13 . The ou...

Embodiment 2

[0041] Embodiment 2, the preparation of supported catalyst:

[0042] 1), the preparation of Co / HZSM5:

[0043] 50mL NH 4 ZSM5 was calcined in a muffle furnace at 200°C for 1h, heated to 350°C for 1h, and then heated to 540°C for 10h to obtain HZSM5; 20g Co(NO 3 ) 2 Prepare 60 mL of deionized aqueous solution, immerse the above-mentioned roasted HZSM5 in it for ion exchange, and immerse for 20 hours; roast the ion-exchanged HZSM5 at 550°C for 6 hours to obtain the finished supported catalyst.

[0044] In this supported catalyst (Co / HZSM5), Co accounts for 15% of the total weight of the supported catalyst.

[0045] 2), activation catalyst:

[0046] Put the above-mentioned 300ml Co / HZSM5 into the packing layer in the middle section of the reactive distillation column 7, and pass an appropriate amount of N through the purge gas pipe 11. 2 To remove the air in the reactive distillation tower 7, N 2 It passes through the pipe 16 and the condenser 6 in turn, and finally is disc...

Embodiment 3

[0049] Embodiment 3, a kind of method based on reaction-separation coupling production tert-butylamine, carries out following steps successively:

[0050] 1), Feed material:

[0051] Storage in raw material tank 1 is the raw material that molar ratio is 1:1 isobutene and ammonia composition, and the loaded catalyst after activation treatment is placed in the middle section of reactive distillation tower 7, and this loaded catalyst is the Co / HZSM5 of 300ml (as implemented obtained in Example 2).

[0052] Open the shut-off valve 22, pressurize the reactive distillation tower 7 through the purge gas pipe 11 and the collecting pipe 13 successively with nitrogen, so that the pressure at the top of the reactive distillation tower 7 reaches 1.5MPa, and this pressure value can be obtained from the pressure gauge 5 informed.

[0053] Then, the shutoff valve 20, the feed pump 2, the shutoff valve 21, the preheater 3, the shutoff valve 23, and the shutoff valve 24 are opened. Under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com