Equipment and method for cracking polyalkyl alpha-cyanacrylate

A technology of cyanoacrylate and polyalkylene, which is applied in the field of equipment used in this cracking method, can solve the problems of high cost of thin film evaporators and the inability to enlarge the output, etc., and achieve reduction in production rate, short heating time, and large evaporation surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

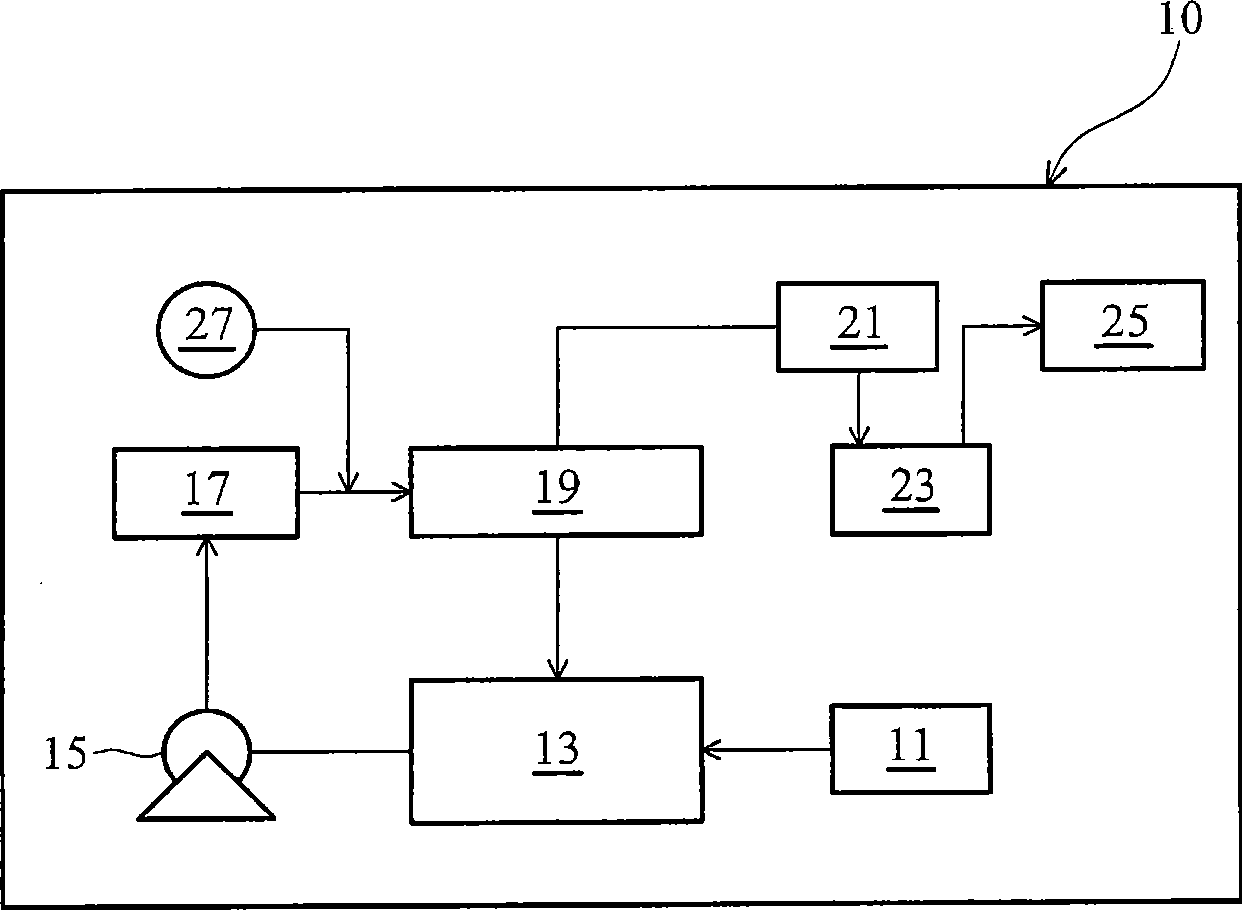

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 (preparation of polymer)

[0042] Take 522g of paraformaldehyde (92%, 16mol) and 1500g of water into a 3L flask, and heat to 90°C to dissolve it. Take 2008g of ethyl α-cyanoacetate, 1 liter of toluene and 15g of piperidine, stir vigorously in a 5L flask equipped with a water separator, and slowly add the above-mentioned formaldehyde solution. This is an exothermic reaction. Pay attention to controlling the feed rate and temperature control so that the reaction temperature does not exceed 80°C. After the addition was complete, it was stirred at 80° C. for 1.5 hours, and then 10 g of phosphoric acid was added. Then raise the temperature to carry out azeotropic dehydration. The azeotropic dehydration starts at 88°C. After most of the water is released, the temperature in the reaction bottle begins to rise, gradually remove the distilled toluene, and raise the temperature to 135°C. Continue at this temperature. Azeotrope until no more water drops drip from th...

Embodiment 2

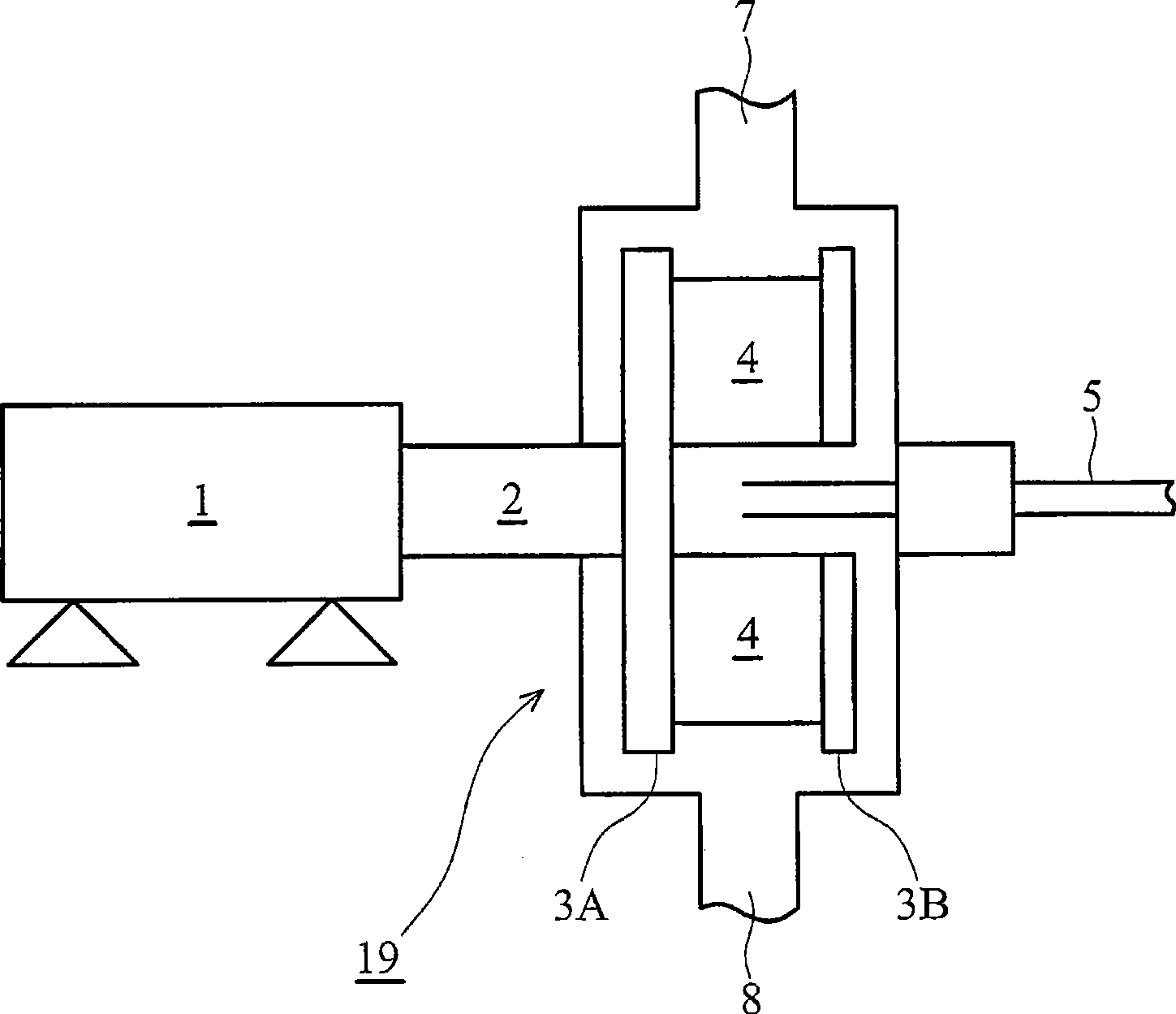

[0043] Embodiment 2 (cleavage reaction)

[0044] Inject enough TCP (about 1 liter) for liquid circulation into the middle tank of the cracking equipment, heat the heat exchanger and circulate the TCP, and preheat the cracking equipment to 170°C. Then put all the TCP into the feed tank, dilute the mixture in the feed tank, then turn on the vacuum pump to lower the pressure to 4 torr, make the raw material mixture suck into the middle tank, circulate cracking and separate the product alkyl group with the supergravity machine of the present invention α-cyanoacrylates and incompletely cracked polyalkyl α-cyanoacrylates. Control the hot oil temperature of the heat exchanger to 220°C, the outlet temperature is about 207°C, and the gas inhibitor SO 2 The flow rate is about 1cc / min, and at the same time, the valve controls the continuous feeding of the raw material mixture to keep the liquid level of the middle tank approximately constant, and the principle is to maintain the liquid ...

Embodiment 3~9

[0045] Embodiment 3~9 (the influence of cracking reaction parameter)

[0046] In Table 1, the present invention has adjusted parameters such as the ratio of polyoxymethylene and ethyl α-cyanoacetate, the temperature of the heat exchanger, the temperature, pressure, and time of the cracking reaction for the polymerization reaction, and measures the yield . It can be clearly found from Table 1 that the yield of ethyl α-cyanoacrylate produced by the equipment and method of the present invention can reach more than 95%.

[0047] Table 1

[0048] Reality

[0049] 8 1.1 / 1 225 216~217 6 3.5 92.2 9 1.1 / 1 220~230 207~219 4 4 95.6

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com