Method for preparing C5 hydrocarbon resin from methyl tetrahydro benzoic anhydride production waste liquor

A technology of methyltetrahydrophthalic anhydride and petroleum resin, applied in the direction of coating, etc., can solve the problems of resin solubility, poor compatibility, difficult chromaticity, softening point, and difficult control of molecular weight, etc. Use value, reduce water and material wastage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

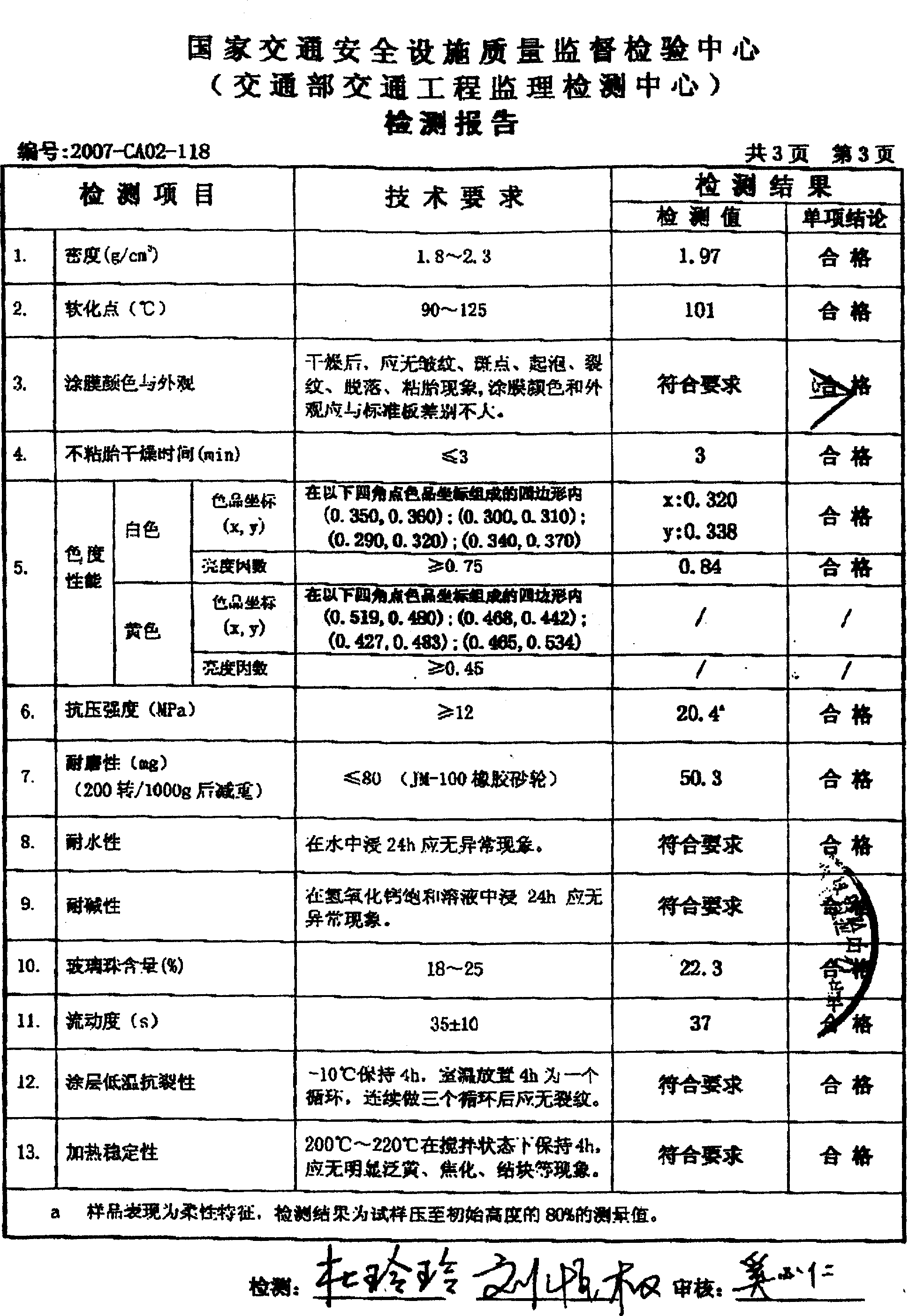

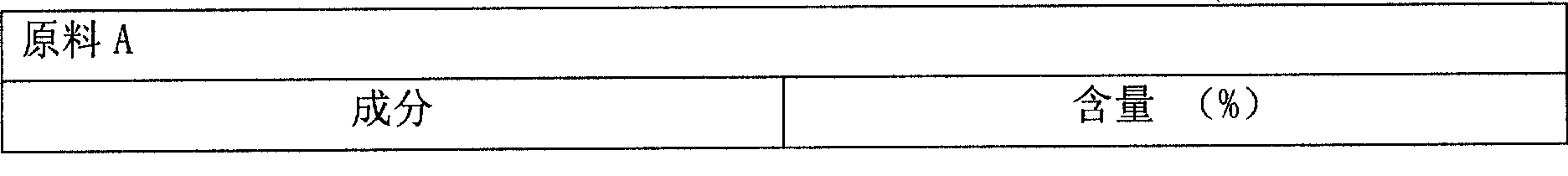

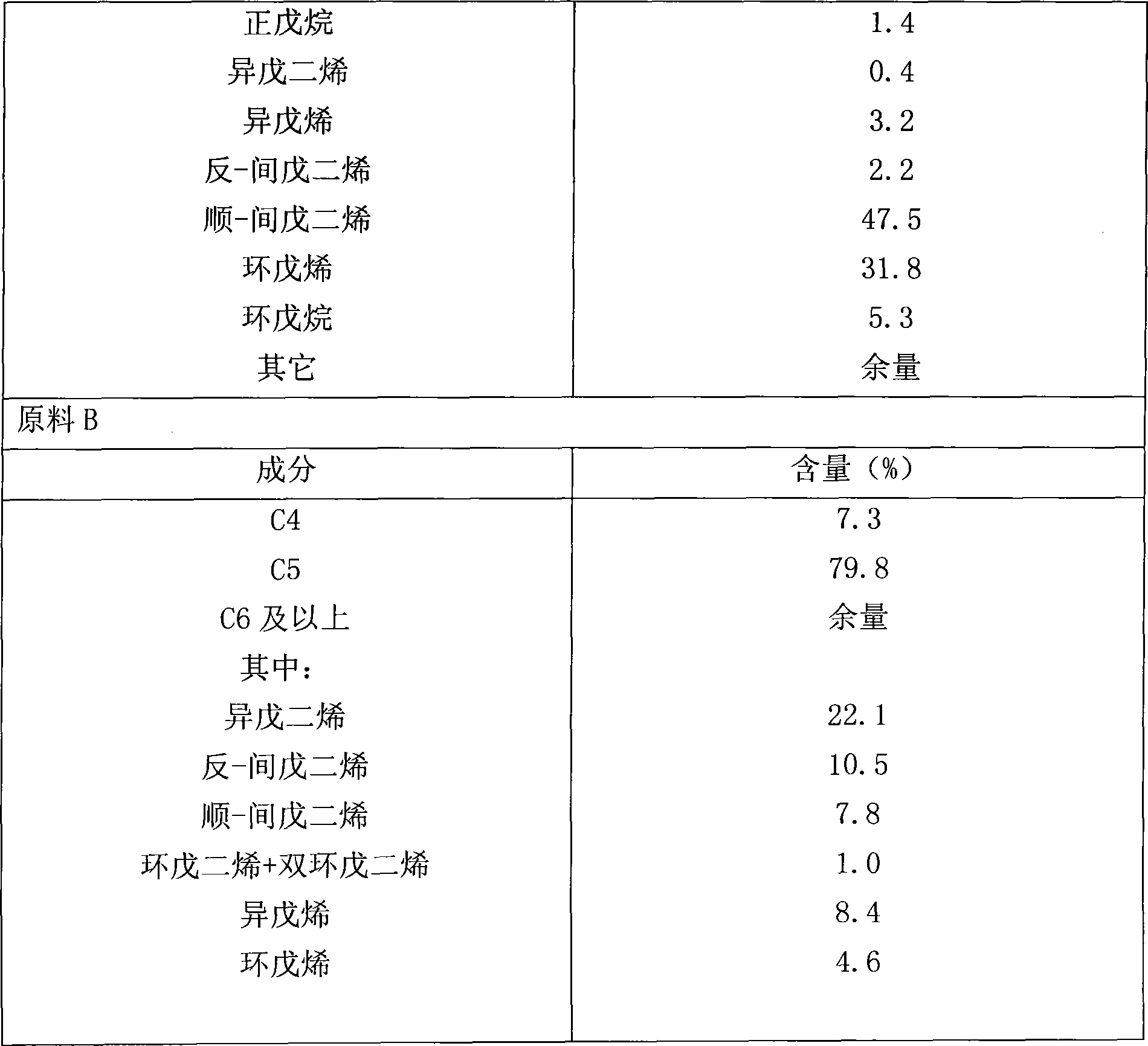

[0027] The components of raw materials A and B used in each embodiment are shown in Table 1, the feed ratio and reaction conditions of raw materials A and B are shown in Table 2, and the main indicators of each embodiment product are shown in Table 3.

[0028] in a 7m 3 In the reaction kettle, add 1.2m 3 C5 light oil solvent, start stirring and jacket cooling water, after pressing the catalyst aluminum trichloride with nitrogen in batches, use a chemical pump to continuously and uniformly add the required amount of raw material A and B mixture during the entire reaction time, and pass Control the water flow rate of the external circulation condenser to control the polymerization reaction at the set temperature. After the feeding is completed and the temperature is kept for 1 hour, after the polymerization reaction is completed, it enters the continuous water washing unit for water washing. Using dynamic and static mixing methods, the catalyst is removed by three-stage continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com