Highly hydrophilic polyamide acid imide, preparation and use in porous membrane

A water polyamide-imide and polyamide-imide technology, which is applied in the field of polymer compounds, can solve the problems of chemical swelling and high production cost of aromatic PAI, and achieves short reaction time, easy porous separation membrane, and easy popularization. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

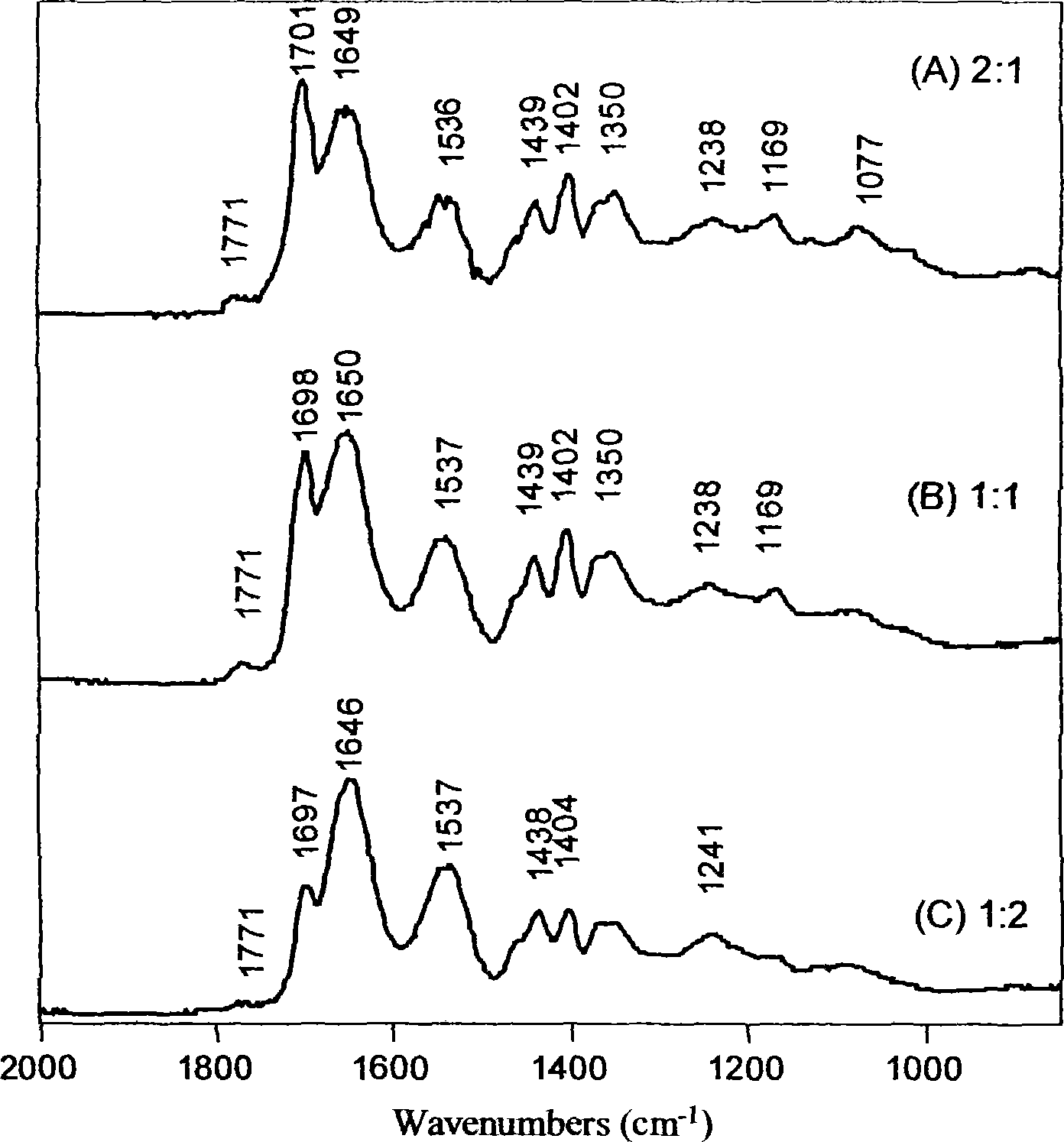

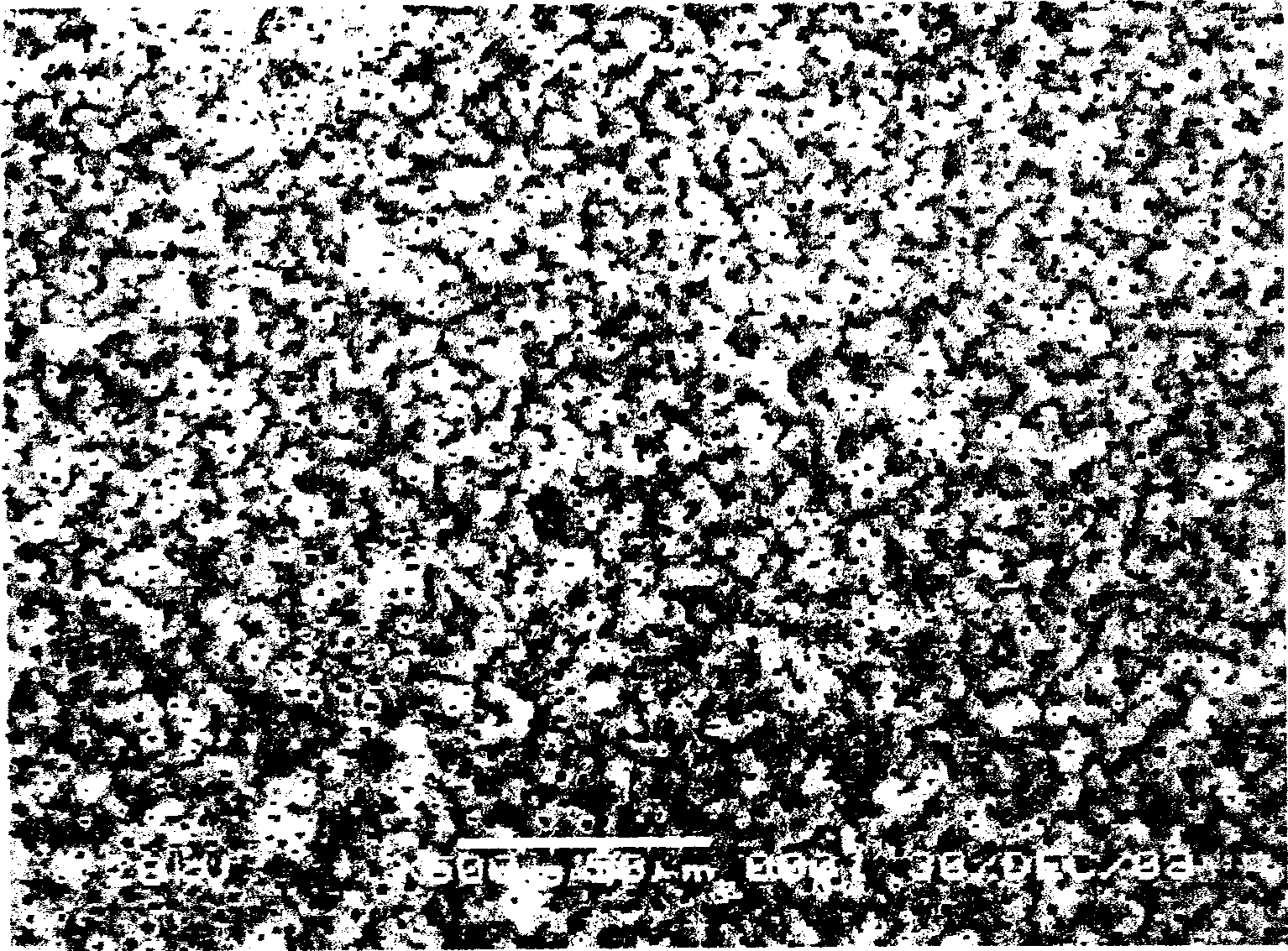

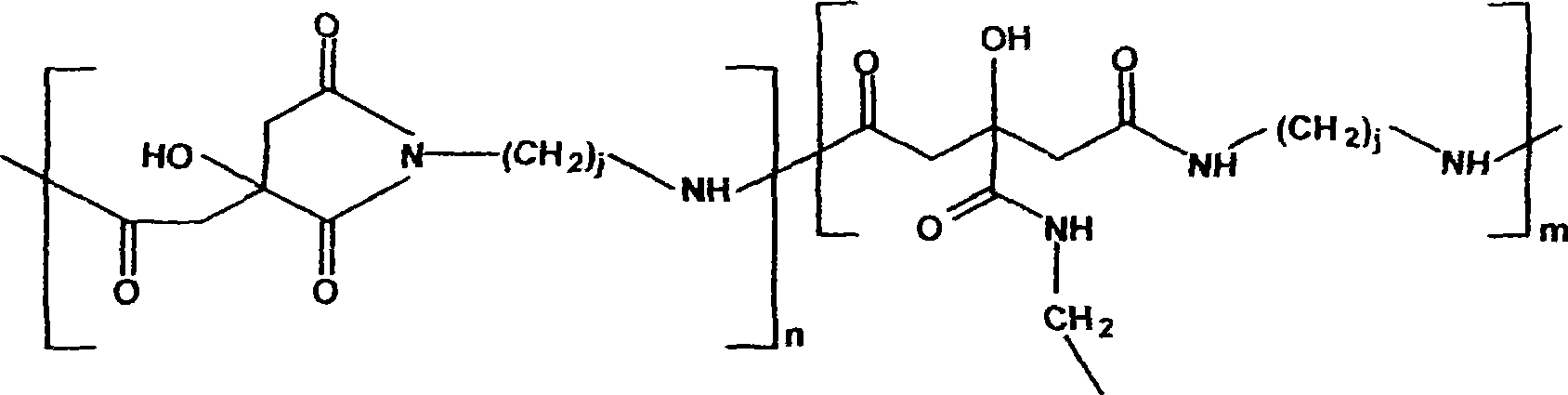

Image

Examples

Embodiment 1

[0042] Mix 30.0mmol of tributyl citrate, 45.0mmol of 1,6-hexamethylenediamine and 2.0mmol of triethylamine into a round-bottomed flask, connect it to a rotary evaporator and evacuate to -0.1MPa, and control the temperature at 50°C After 8 hours of reaction, the intermediate was obtained, transferred to a glass container or a metal mold, and continued to slowly heat up to 160°C in vacuum, reacted for 3 hours, and kept the temperature at 160°C for 3 hours, then continued to slowly heat up to 200°C, kept at Vacuum reaction at 200°C for 5 hours to obtain polyamideimide with a glass transition temperature of 217°C.

Embodiment 2

[0044] Mix 20.0mmol of tributyl citrate, 15.0mmol of butanediamine and 2.0mmol of pyridine into a round-bottomed flask, connect it to a rotary evaporator, evacuate to about -0.04MPa, and react at 60°C for 2h. Then, it was transferred to a vacuum oven and heated at 150° C. for 12 hours, and continued to react at 220° C. for 5 hours to obtain a polyamideimide with a glass transition temperature of 110° C.

Embodiment 3

[0046] Mix 10.0mmol of tributyl citrate, 30.0mmol of 1,6-hexanediamine and 50mL of N,N-dimethylformamide, heat and evacuate at 60°C to -0.04MPa for 3 hours, and continue at -0.1 MPa was reacted for 12 hours, then the temperature was raised to 150°C, and the reaction was carried out in vacuum for 12 hours, and the temperature was raised to 200°C to obtain polyamide-imide with a glass transition temperature of 145°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com