Security heating method for color-coating line paint curing oven

A paint curing and heating method technology, which is applied in the production of harmful gas treatment and the utilization of waste gas from color coating lines, can solve the problems of many burners, large energy consumption, waste of heat energy, etc., to reduce investment, reduce energy consumption, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

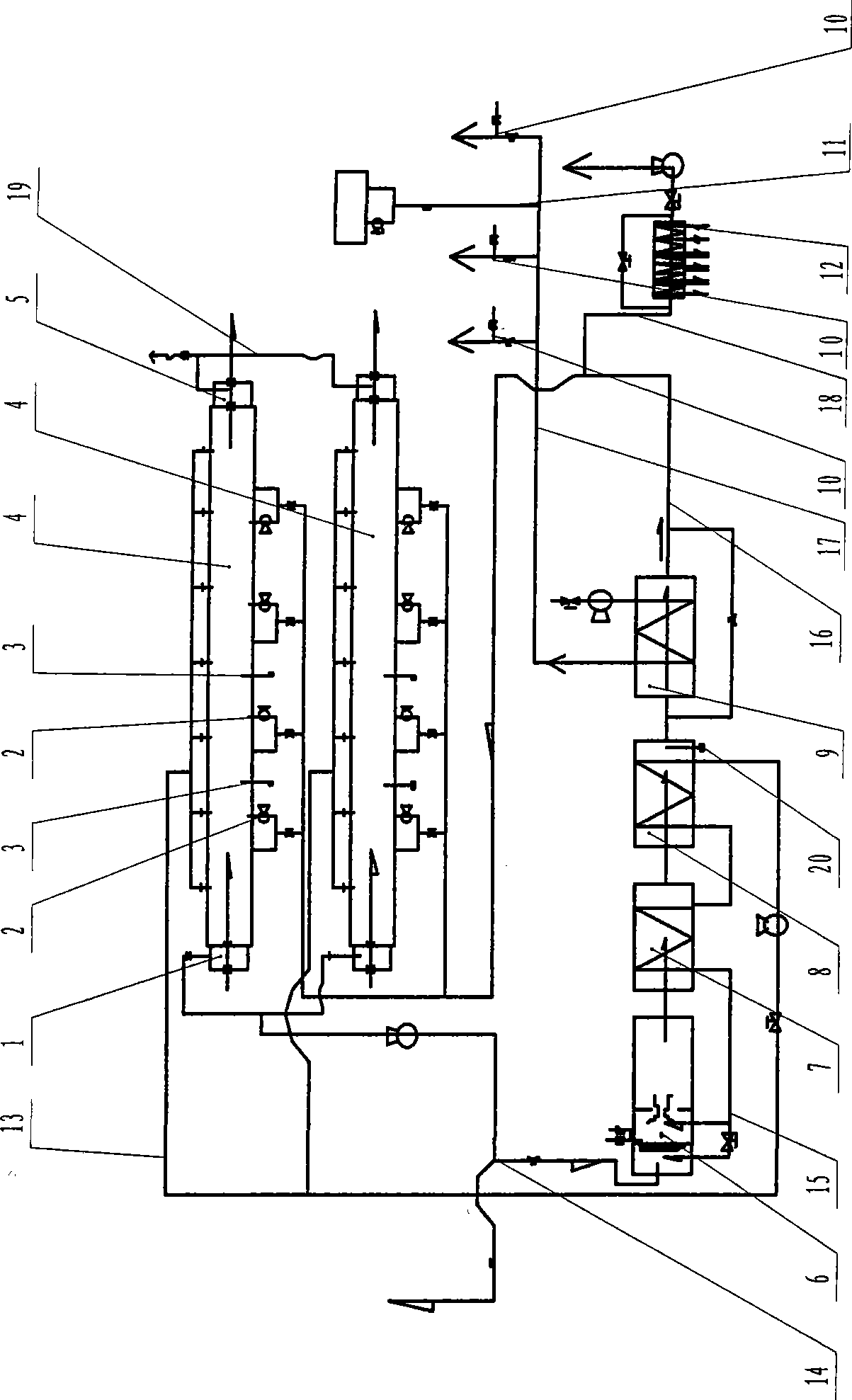

[0018] as attached figure 1 The waste gas containing organic solvent in the shown curing furnace 4 is collected by the solvent-rich waste gas pipeline 13 and then passes through the primary waste gas heat exchanger 7 and the secondary waste gas heat exchanger 8 to increase its temperature, and then enters the incineration chamber 6 to be mixed with natural gas and The premixed gas of the air is burned together in the burner, and the fuel is used as the heating heat source, and the temperature of the cracking chamber is controlled at the cracking point to achieve the purpose of cracking and purifying the waste gas. After the exhaust gas enters the cracking chamber, the temperature is controlled above the cracking point. Under the high temperature condition above the cracking point, the solvent in the exhaust gas is cracked and burned, releasing a large amount of heat energy, generating carbon dioxide and water, and consuming most of the oxygen in the exhaust gas. Nitrogen in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com