Optical fiber coupling outputting vertical cavity surface emitting semiconductor laser device

A technology of vertical cavity surface emission and fiber coupling, which is applied to semiconductor lasers, structural details of semiconductor lasers, lasers, etc., to achieve the effects of low cost, stable power, and simple equipment and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

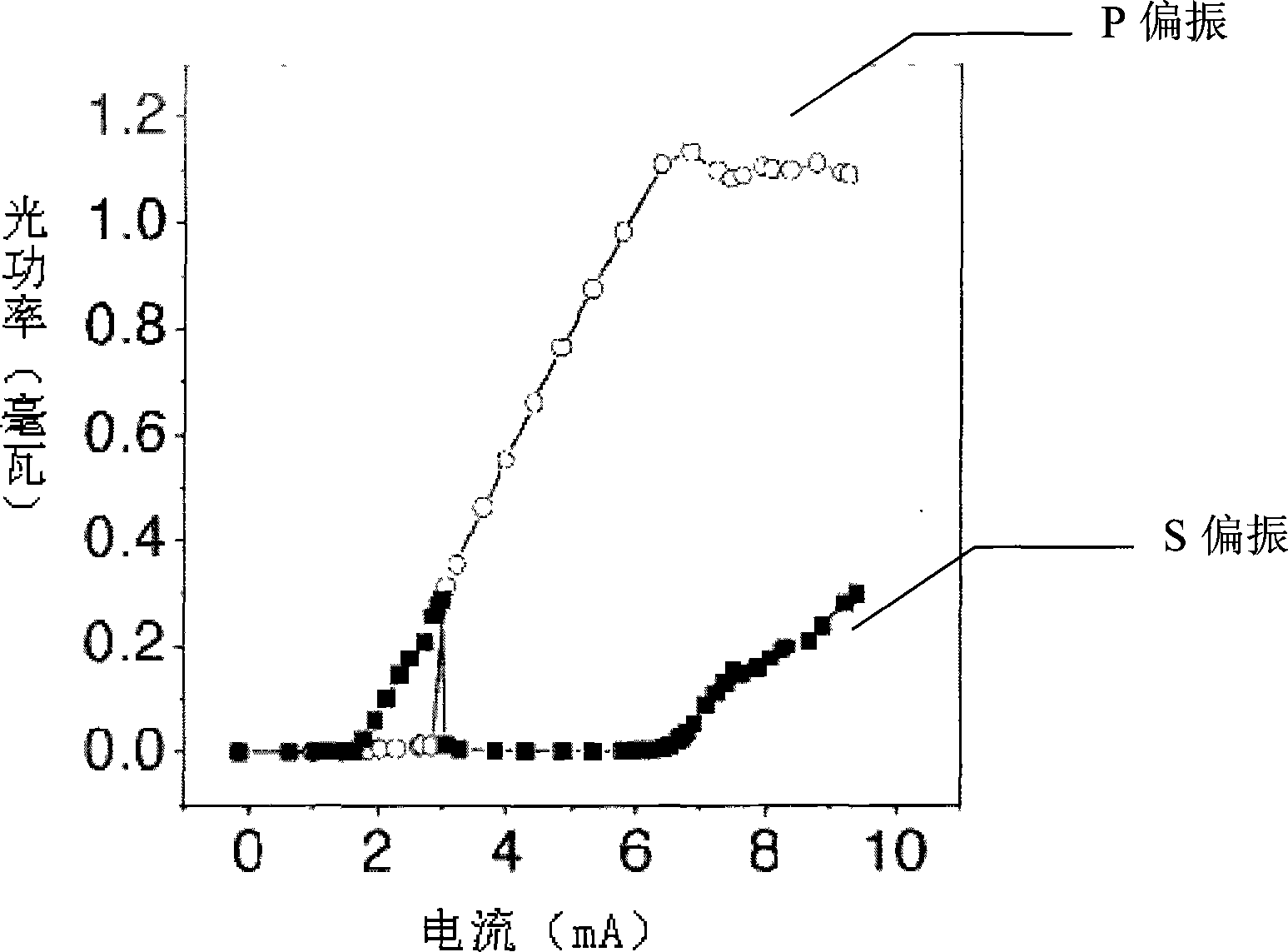

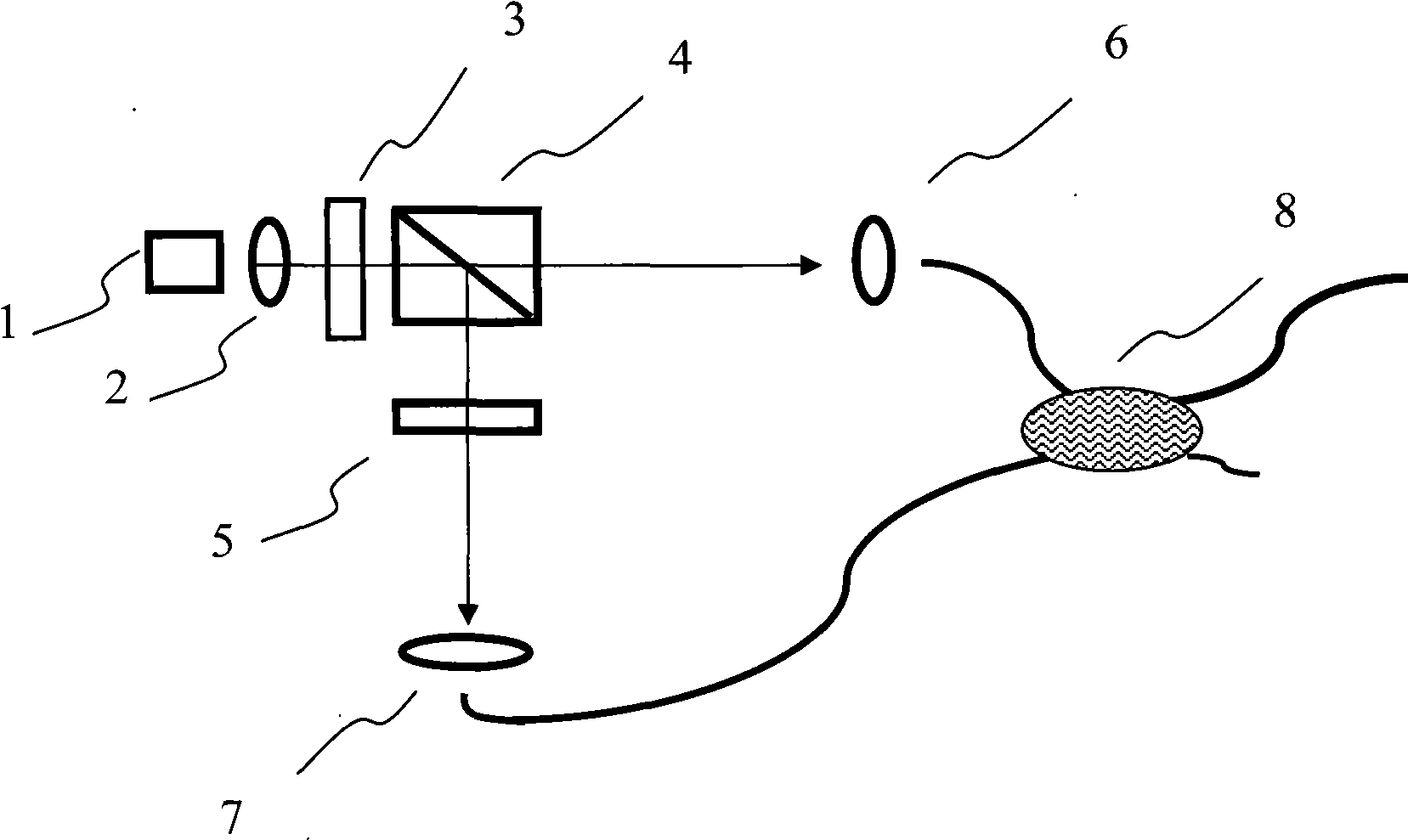

Embodiment 1

[0025] The working process of embodiment 1 is as follows (illustrate with the system requirement output p light as example, if require to output s light, whole process and p light output are corresponding): the semiconductor laser 1 output by vertical cavity surface emission contains p light and The light of the s-light component becomes parallel light through the collimating lens 2, rotates the direction of the first half-wave plate 3 to make it match the optical axis of the polarization beam splitter prism 4, and passes through the p-light of the polarization beam splitter prism 4 forward, The s light is reflected downward by the polarization beam splitter prism 4 , and the p light is coupled to the input fiber of the coupler 8 through the first coupling lens 6 and enters the coupler 8 . Described s light is reflected downwards through polarization beam splitter prism 4, and the optical axis of described second half-wave plate 5 and the polarization direction of s light becom...

Embodiment 2

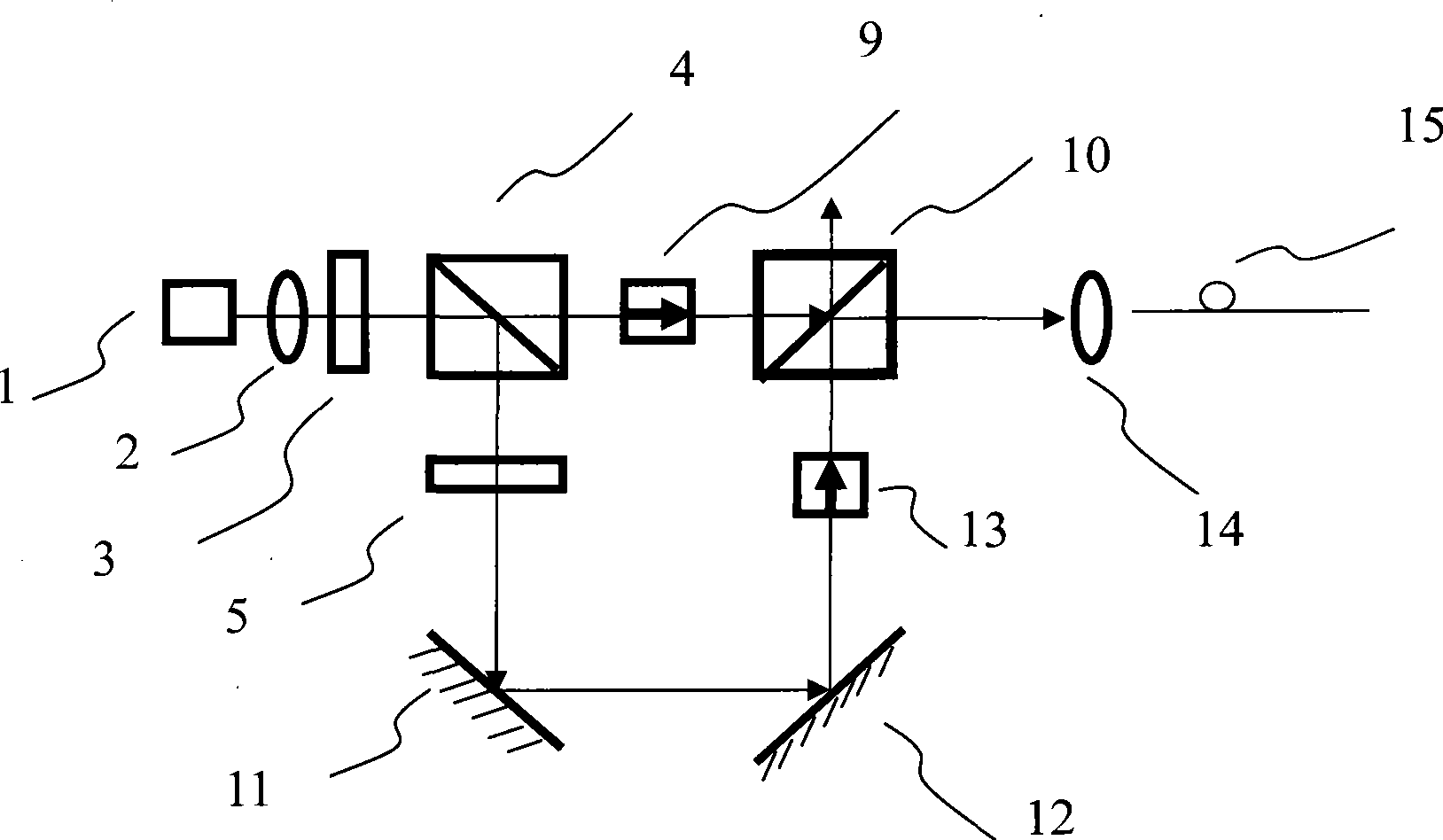

[0027] The working process of embodiment 2 is as follows (illustrate with the example that the system requires the output of p light, if the output of s light is required, the whole process corresponds to the output of p light): the output of the semiconductor laser 1 output by the vertical cavity surface contains p light and The light of the s-light component becomes parallel light through the collimating lens 2, and the light of the two polarization directions is rotated by the first half-wave plate 3, so that it matches the optical axis of the polarization beam splitting prism 4, and passes through the polarization beam splitting prism 4 After the p light passes through the front, the s light is reflected downward, the optical axis of the second half-wave plate 5 is 45° to the polarization direction of the s light, and the s light becomes p light after passing through the second half wave plate 5, and passes through the second half wave plate 5 Reflections from the first ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com