Technique for improving purity of diphtheria toxoid

A diphtheria toxoid and purity technology, which is applied in the field of improving the purity of diphtheria toxoid, can solve problems such as adverse reactions and inability to inhibit allergens, and achieve the effect of ensuring safety and stabilizing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

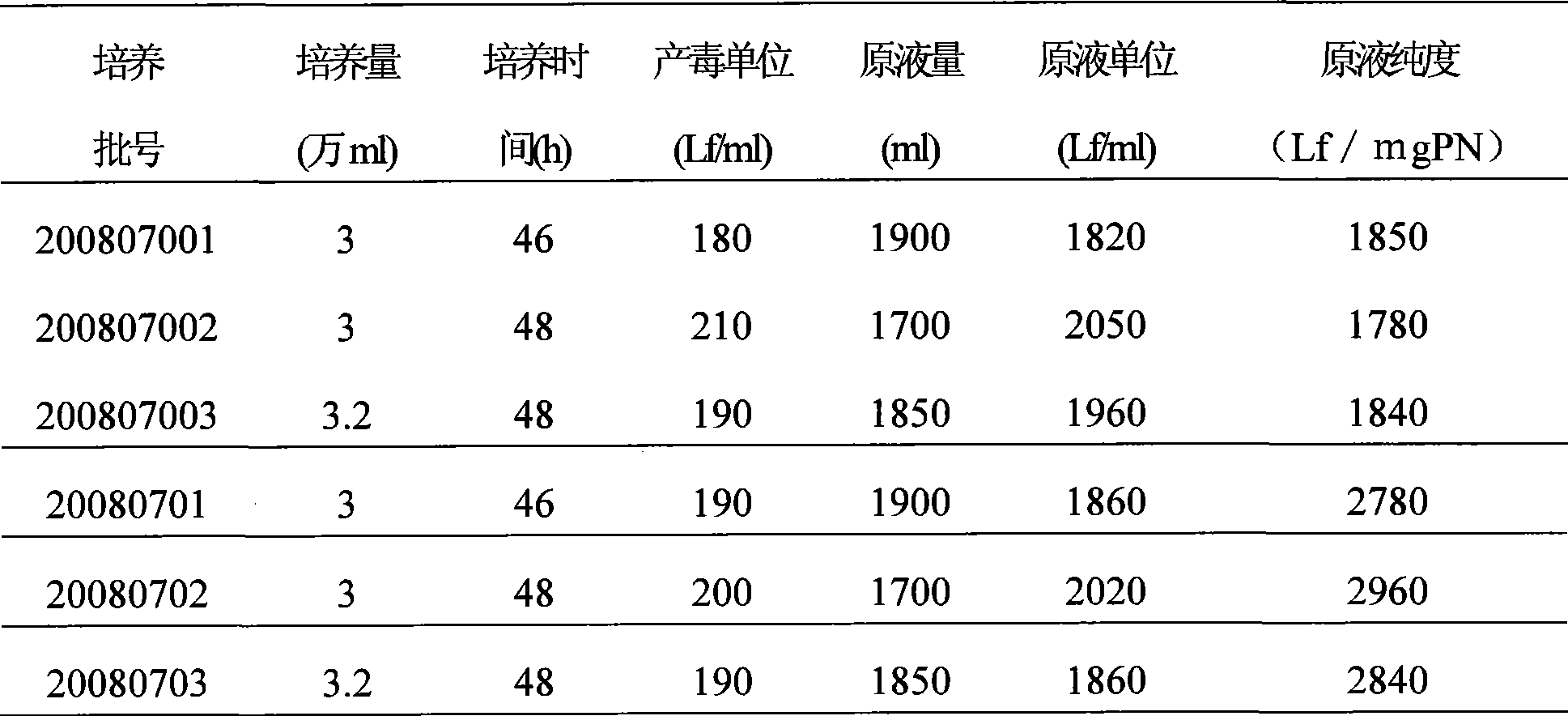

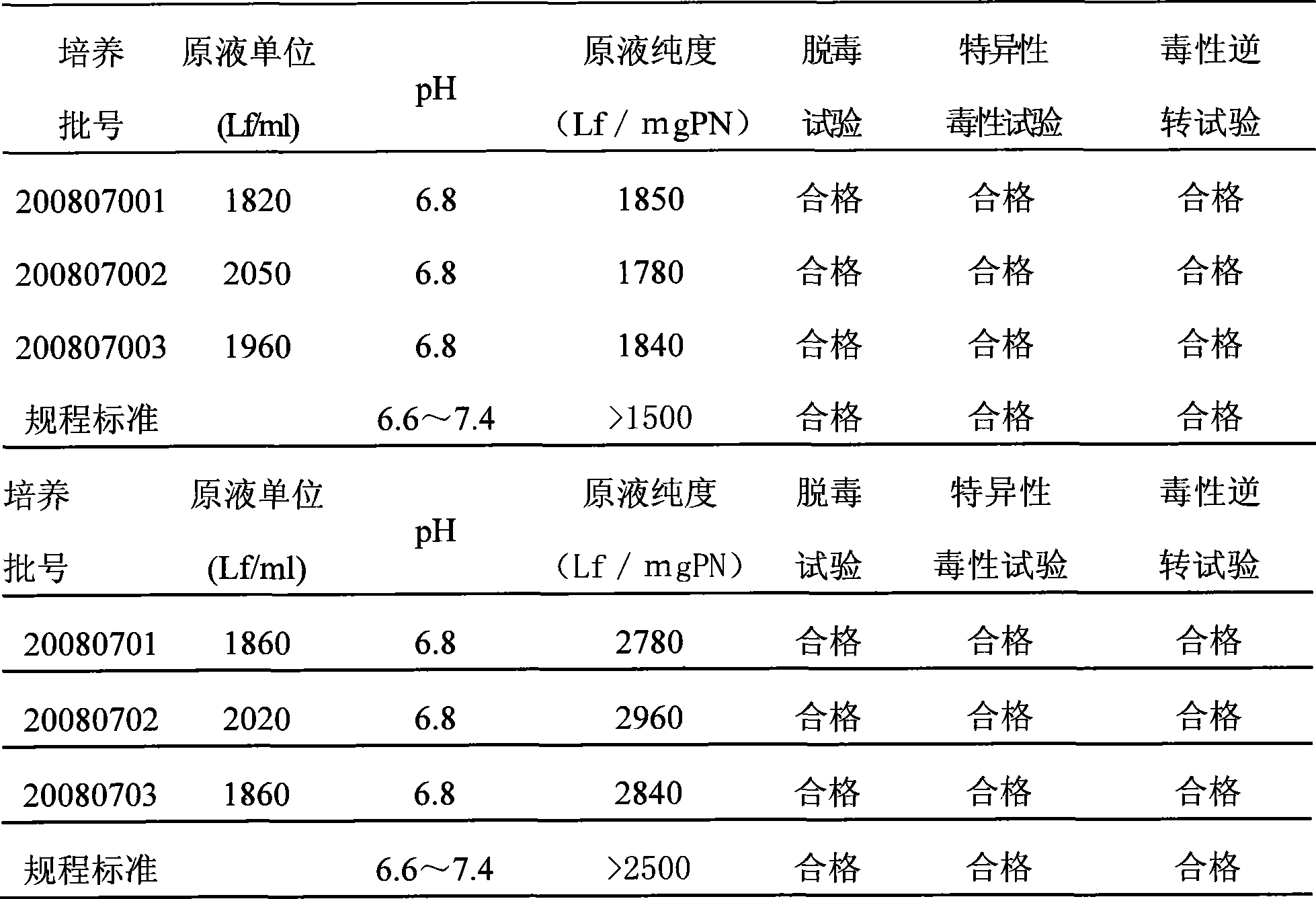

[0013] Example 1: A process for improving the purity of diphtheria toxoid, the production process is solid medium subculture → liquid medium fermenter cultivation → centrifugation to remove bacteria → one-stage salting out → two-stage salting out → ultrafiltration desalination → Gel Filtration → Sterilization Filtration → Detoxification → Preservation of Raw Solution → Semi-finished Product Preparation → Finished Product, the liquid medium in the liquid medium fermenter is treated to remove protein with a molecular weight above 50,000, and basically only diphtheria toxin is contained in the culture harvest If the molecular weight is above 50,000, proteins with a molecular weight below 50,000 and other miscellaneous proteins in the harvest liquid are further removed by salting out and gel filtration to obtain high-purity diphtheria toxin.

[0014] Process description: (1) Strain preparation: Diphtheria 38007 strains were opened and inoculated on Lu's serum slant medium, cultured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com