Micro super capacitor applied for micro system and production process thereof

A supercapacitor and microsystem technology, applied in the manufacture of capacitors, hybrid/electric double-layer capacitors, electrolytic capacitors, etc., can solve the problems of large electrode resistance, achieve low internal resistance, high activity, and improve power storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention proposes a micro supercapacitor applied to a microsystem based on MEMS micromachining technology and a manufacturing method thereof. The micro-supercapacitor adopts a unique inter-electrode support body and a liquid storage cavity space structure, and is composed of positive and negative electrodes of ruthenium oxide and KOH electrolyte sealed in a polyimide encapsulation layer. A micro supercapacitor with high power, simple structure, convenient processing, and reliable performance.

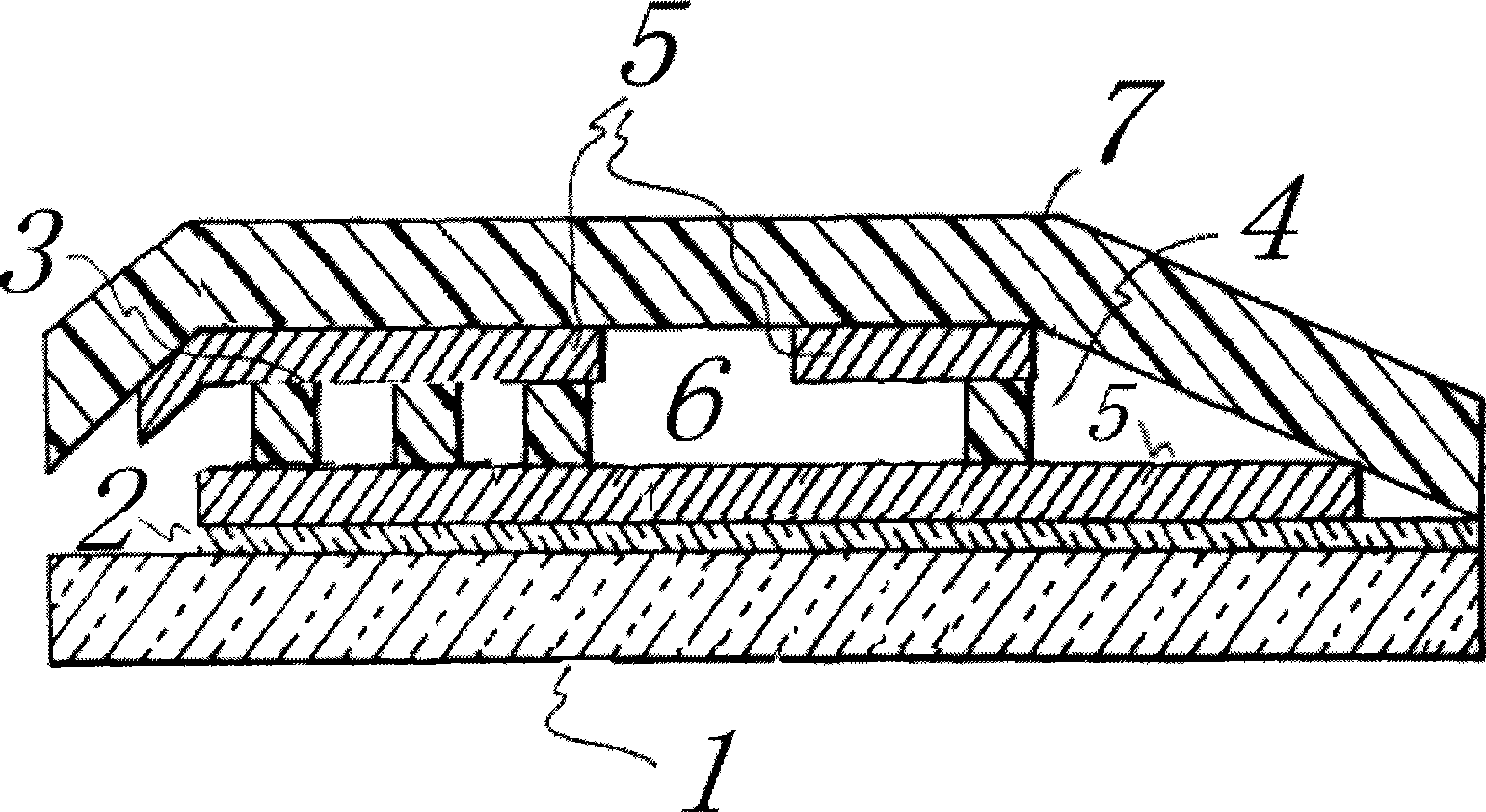

[0014] figure 1 A schematic diagram of the spatial structure of the micro supercapacitor is shown. The structure and process flow of the micro-supercapacitor described in the figure are as follows: a layer of nickel metal film collector 2 and a ruthenium oxide film 5 are prepared on a silicon substrate 1, and an inter-electrode support structure 3 and a ruthenium oxide active film 5 are formed. The wall structure 4 of the liquid storage cavity, and the ruthenium oxide film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com