Preparation of urylene dimethylamino-propane and dichloroethyl ether copolymer

A technology of dimethylaminopropane and dimethylaminopropylamine, which is applied in the field of preparation of uridine dimethylaminopropane and dichloroethyl ether copolymer, can solve the problem of low conversion rate of dimethylaminopropane, unstable average molecular weight, and poor electroplating effect. Stability and other issues, to achieve environmental friendliness, ensure product purity and color, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

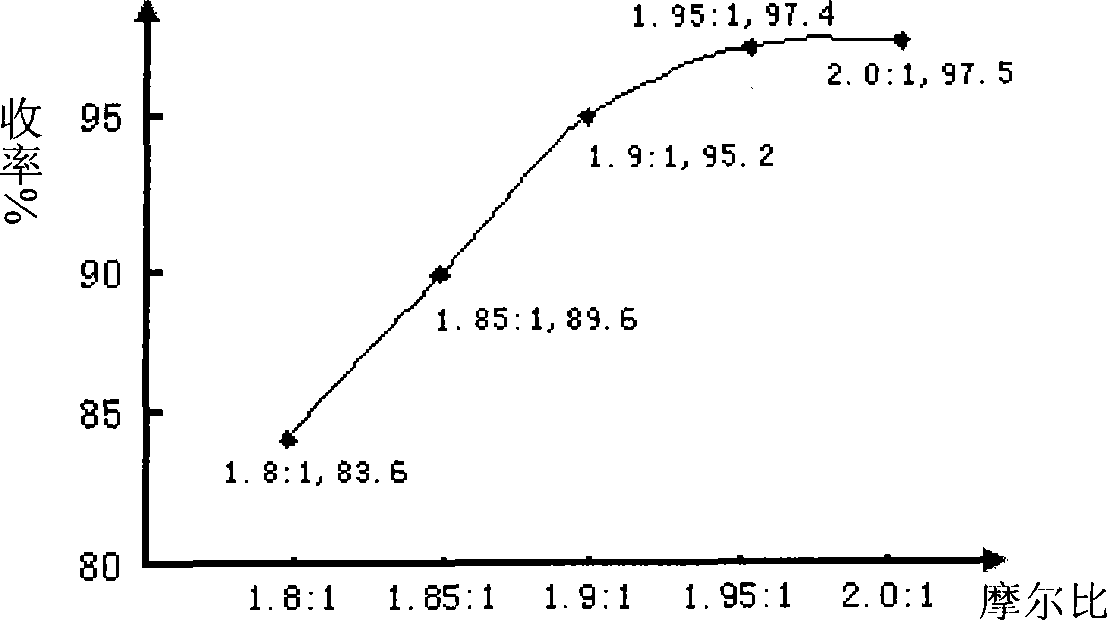

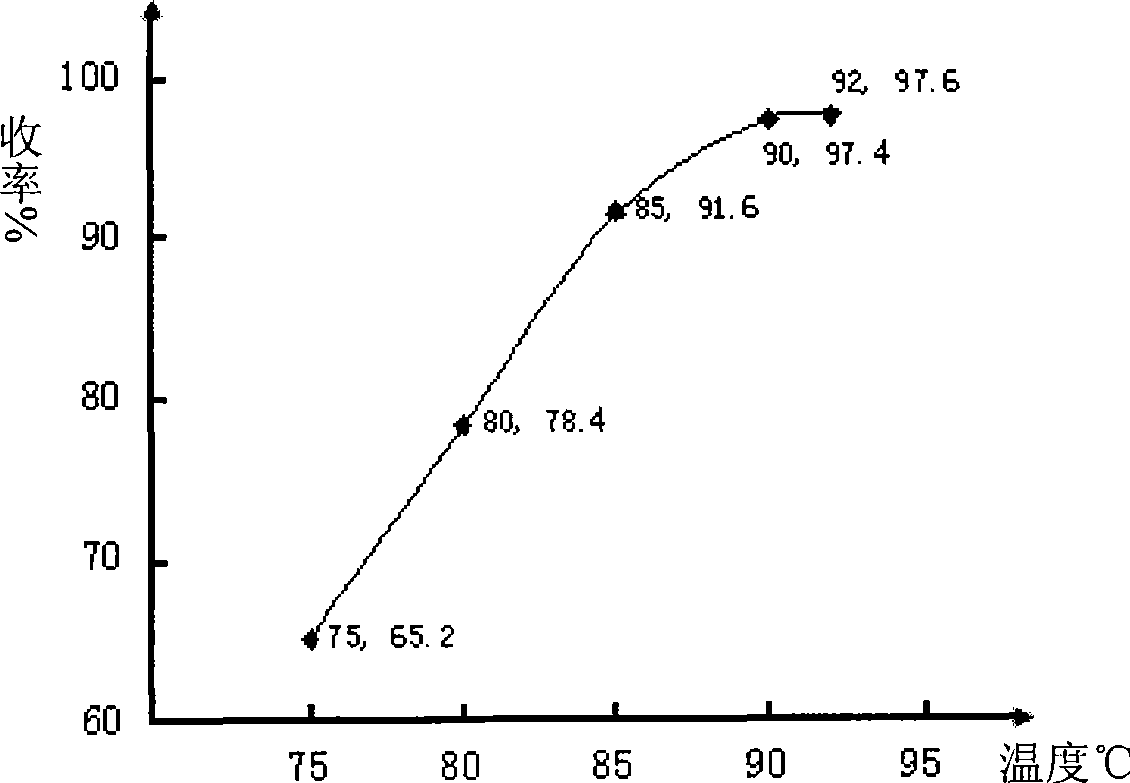

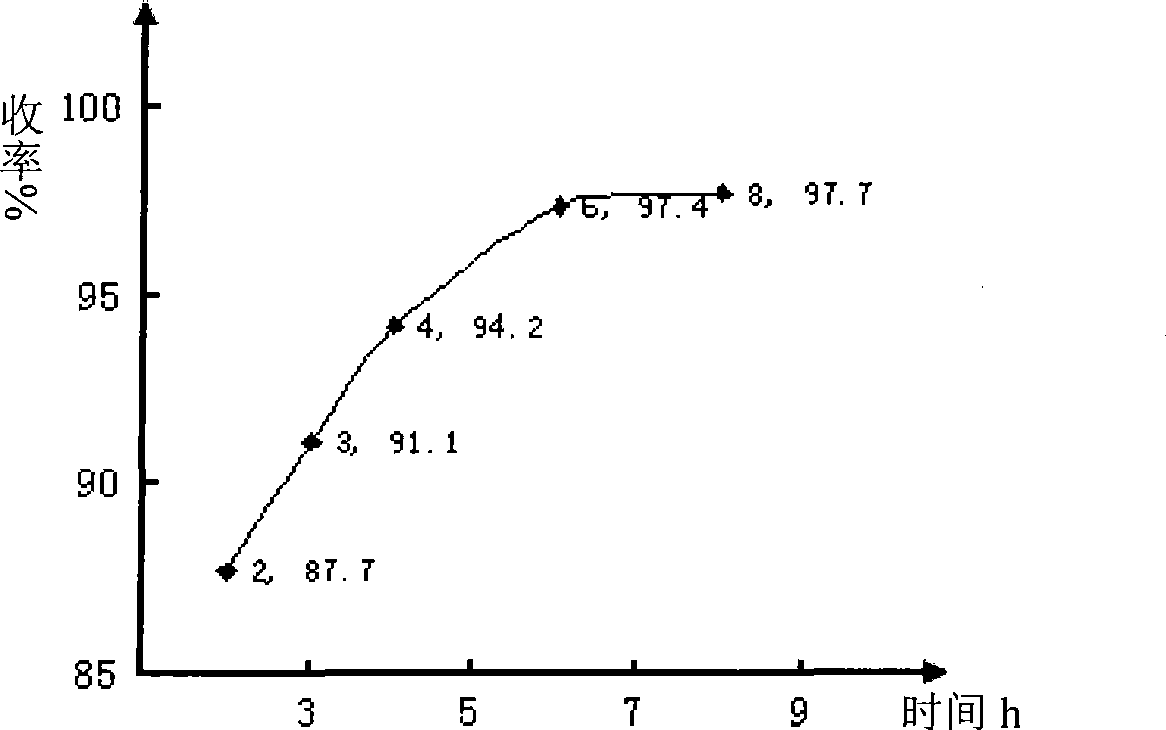

[0057] The preparation method of urethane dimethylaminopropane and dichloroether copolymer, it comprises following reaction steps:

[0058] ①. The synthesis of urea-dimethylaminopropane: add dimethylaminopropylamine: urea into the reactor at a ratio of 1.8:1, stir while adding, feed an inert gas into the reactor, and add a catalyst, the temperature is 100°C, Keeping the temperature for 8 hours, then raising the temperature to 140°C, recovering the ammonia gas released during the reaction (using dilute sulfuric acid to absorb ammonia gas) to obtain the crude uridine dimethylaminopropane, and then rectifying to obtain the fine urea dimethylaminopropane;

[0059] ②. Synthesis of copolymer: put ureadimethylamidopropane: β, β-dichloroethyl ether: water into the reaction kettle at the ratio of 0.5:1:12, stir while adding, react under reflux conditions for 13 hours, then add Molecular weight regulator, keep warm for 3 hours, add activated carbon (the mass of activated carbon is 1-10%...

Embodiment 2

[0063] The preparation method of uridine dimethylaminopropane and dichloroether copolymer is characterized in that it comprises the following reaction steps:

[0064] ①. The synthesis of urea-dimethylaminopropane: add dimethylaminopropylamine: urea to the reaction kettle at a ratio of 2.0:1, stir while adding, feed inert gas into the reaction kettle, and add a catalyst, the temperature is 75°C, Keeping warm for 2 hours, then raising the temperature to 140°C, recovering the ammonia gas released during the reaction to obtain the crude uridine dimethylaminopropane, and then rectifying to obtain the refined urea dimethylaminopropane;

[0065] ②. Synthesis of copolymer: put ureadimethyaminopropane: β, β-dichloroethyl ether: water into the reaction kettle at the ratio of 1.2:1:12, stir while adding, react under reflux conditions for 21 hours, and then add Molecular weight regulator, heat preservation reaction for 1 hour, add activated carbon (the mass of activated carbon is 1-10% of...

Embodiment 3

[0069] The preparation method of urethane dimethylaminopropane and dichloroether copolymer, it comprises following reaction steps:

[0070] ①. The synthesis of urethane dimethylaminopropane: add dimethylaminopropylamine: urea to the reactor at a ratio of 1.9:1, stir while adding, feed inert gas into the reactor, and add a catalyst, the temperature is 90°C, Keeping warm for 5 hours, then raising the temperature to 140°C, recovering the ammonia gas released during the reaction to obtain the crude uridine dimethylaminopropane, and then rectifying to obtain the refined urea dimethylaminopropane;

[0071] ②. Synthesis of copolymer: Put ureadimethylamidopropane: β, β-dichloroethyl ether: water into the reaction kettle at 0.9:1:12, stir while adding, react under reflux conditions for 17 hours, and then add Molecular weight regulator, heat preservation reaction for 2 hours, add activated carbon to decolorize, then distill off excess water to obtain uridine dimethylaminopropane and dic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com