Thermal insulation wall

A technology for thermal insulation and wall body, applied in the direction of walls, solid waste management, building components, etc., can solve the problems of unstable construction quality, unfavorable promotion and application, complex construction process, etc., achieves remarkable thermal insulation effect, and avoids pollution. Environmental and material workability is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

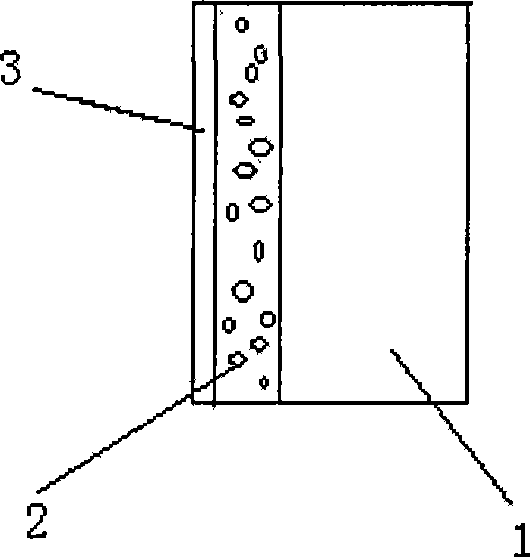

[0013] Embodiment 1: A thermal insulation wall, which includes an enclosure wall 1, a stucco layer 2 and a finish layer 3, the enclosure wall 1 is composed of concrete beams and columns and light insulation brick masonry, and the enclosure wall 1 The masonry mortar used in and the plastering mortar used in the stucco layer 2 are both special mortars for lightweight insulation brick masonry, and their raw materials and component ratios are as follows: 15 parts of fly ash, 20 parts of perlite , 7 parts of bentonite, 2 parts of hydrated lime powder, 1 part of cellulose ether, 350 parts of sand, 50 parts of pottery sand, and 100 parts of cement.

[0014] The fly ash is class II fly ash. The perlite has a bulk density of less than 120 / m 3 Type II expanded perlite. The bentonite is modified sodium bentonite. The sand was scrubbed, dried natural sand. The pottery sand is screened coal ash powder pottery sand. The cement is ordinary Portland cement with a strength grade of 42.5. ...

Embodiment 2

[0015] Embodiment 2: A thermal insulation wall, which includes an enclosure wall 1, a stucco layer 2 and a finish layer 3, the enclosure wall 1 is composed of concrete beams and columns and lightweight thermal insulation brick masonry, and the enclosure wall 1 The masonry mortar used in and the plastering mortar used in the stucco layer 2 are both special mortars for lightweight insulation brick masonry, and their raw materials and component ratios are as follows: 35 parts of fly ash, 40 parts of perlite , 1 part of bentonite, 10 parts of hydrated lime powder, 1 part of cellulose ether, 200 parts of sand, 100 parts of pottery sand, and 100 parts of cement.

[0016] The fly ash is Class I fly ash. The perlite has a bulk density of less than 120 / m 3 Type II expanded perlite. The bentonite is modified sodium bentonite. The sand was scrubbed, dried quartz sand. The ceramic sand is screened shale ceramsite. The cement is slag cement of strength class 42.5.

Embodiment 3

[0017] Embodiment 3: A thermal insulation wall, which includes an enclosure wall 1, a stucco layer 2 and a finish layer 3, the enclosure wall 1 is composed of concrete beams and columns and lightweight thermal insulation brick masonry, and the enclosure wall 1 The masonry mortar used in and the plastering mortar used in the stucco layer 2 are both special mortars for lightweight insulation brick masonry, and their raw materials and component ratios are as follows: 20 parts of fly ash, 30 parts of perlite , 4 parts of bentonite, 5 parts of slaked lime powder, 1 cellulose ether, 300 parts of sand, 80 parts of pottery sand, and 100 parts of cement.

[0018] The fly ash is class II fly ash. The perlite has a bulk density of less than 120 / m 3 Type II expanded perlite. The bentonite is modified sodium bentonite. The sand was scrubbed, dried natural sand. The ceramic sand is a mixture of screened fly ash ceramsite and shale ceramsite. The cement is ordinary Portland cement with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com