Water electrolytic hydrogen production and minitype gas turbine-switch reluctance motor united generating set

A technology of micro gas turbine and switched reluctance motor, applied in electromechanical devices, electrical components, electrolysis process, etc., can solve the problems of high-speed permanent magnet synchronous motor easy to lose magnetism, expensive reduction gear box, poor mechanical characteristics of rotor, etc., to achieve Enhance the mechanical characteristics of the rotor, improve the integration of the system, and suppress the effect of harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

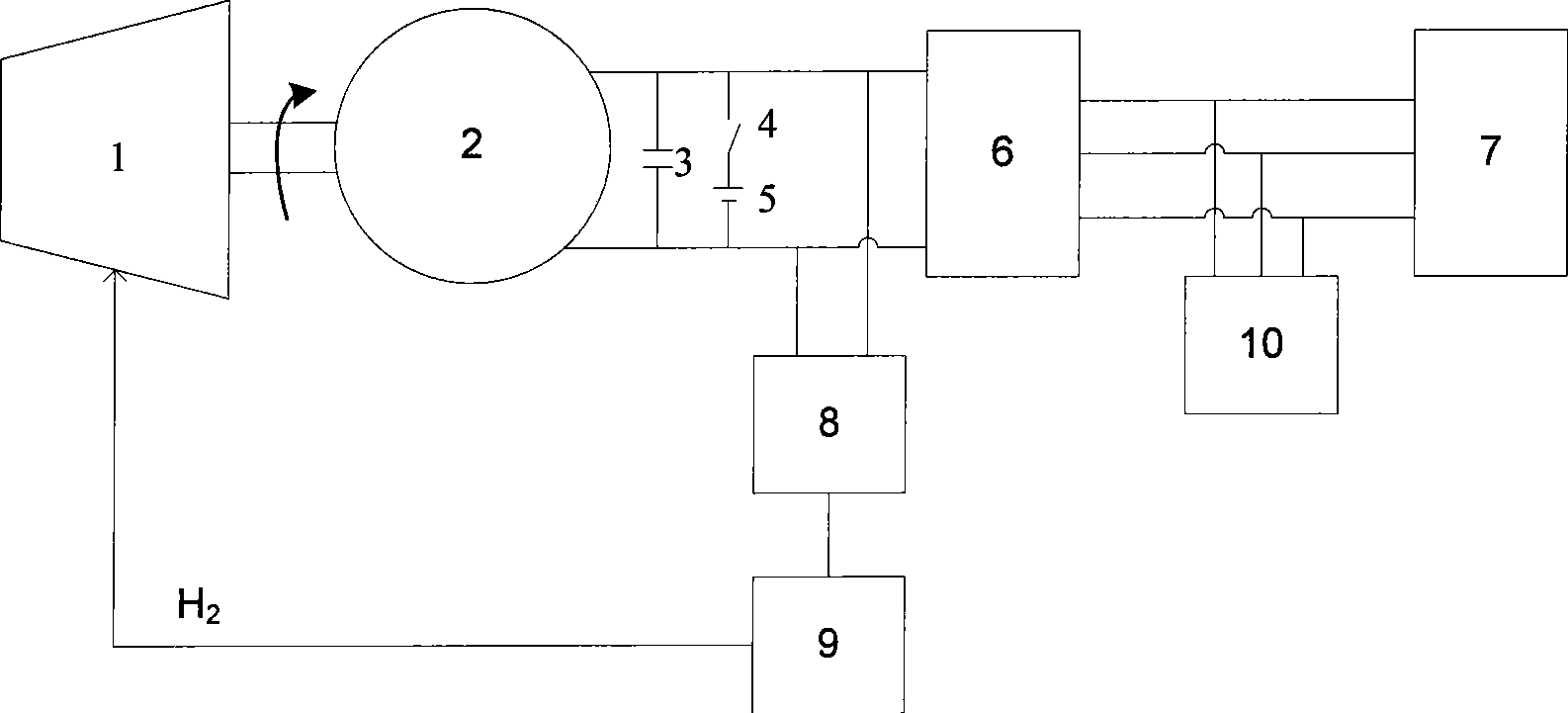

[0010] refer to figure 1 , figure 1 It is a block diagram of a combined power generation device of a micro gas turbine and water electrolysis hydrogen production equipment proposed by the present invention. As shown in the figure, the device mainly includes: a micro gas turbine 1, which is used to provide the motive force for the 6 / 4-pole switched reluctance generator 2; a filter capacitor 3 is responsible for filtering the direct current, and also participates in the excitation work of the switched reluctance generator The switch 4 and the DC power supply 5 are mainly used for the start-up of the switched reluctance generator; the inverter 6 is responsible for connecting the DC bus to the power grid 7 and the electric load 10; the DC-DC power converter 8 is mainly It is responsible for converting the direct current into the voltage level required by the water electrolysis hydrogen production equipment 9 for hydrogen production and energy storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com