Preparation method of protein feed in oilseed dregs

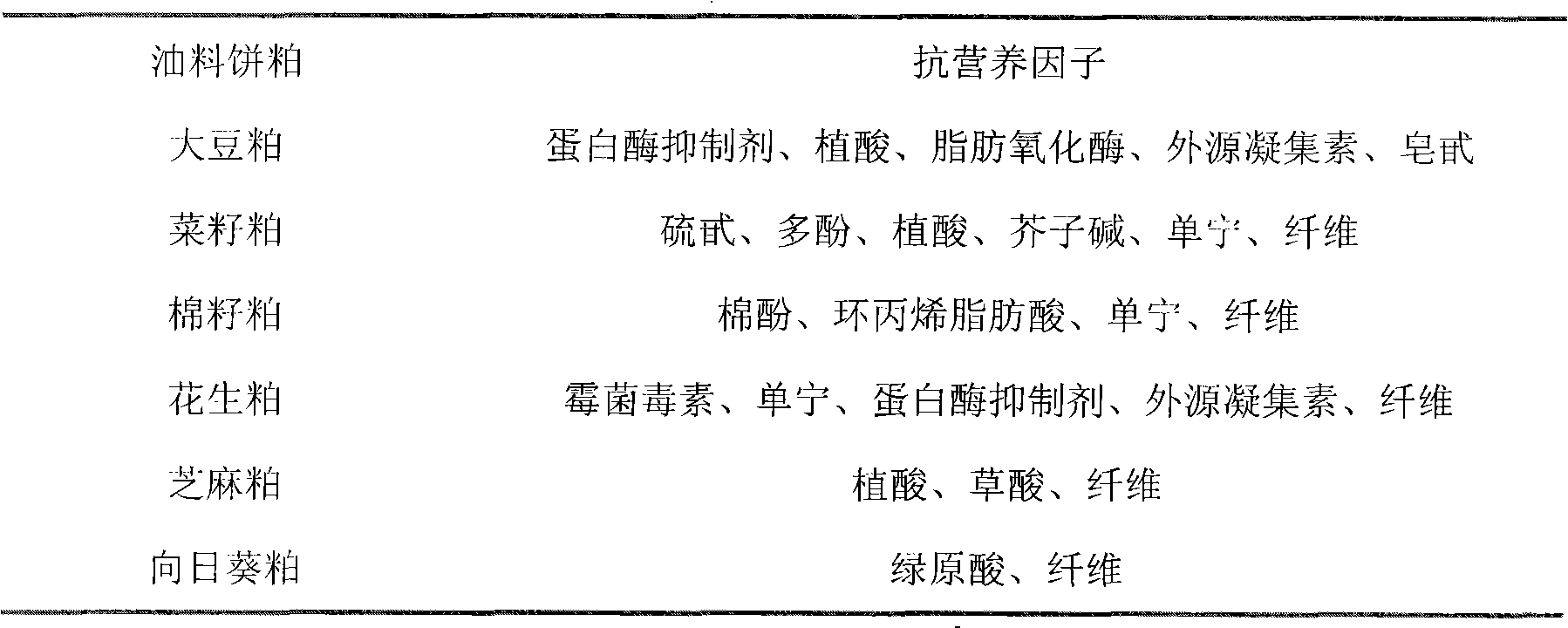

A technology for cake protein and oilseeds, applied in animal feed, animal feed, application and other directions, can solve the problems of single effect, loss of crude oil cake protein, and production of a large number of poisons, and achieve significant effects, promote digestion and growth, and improve The effect of feed conversion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

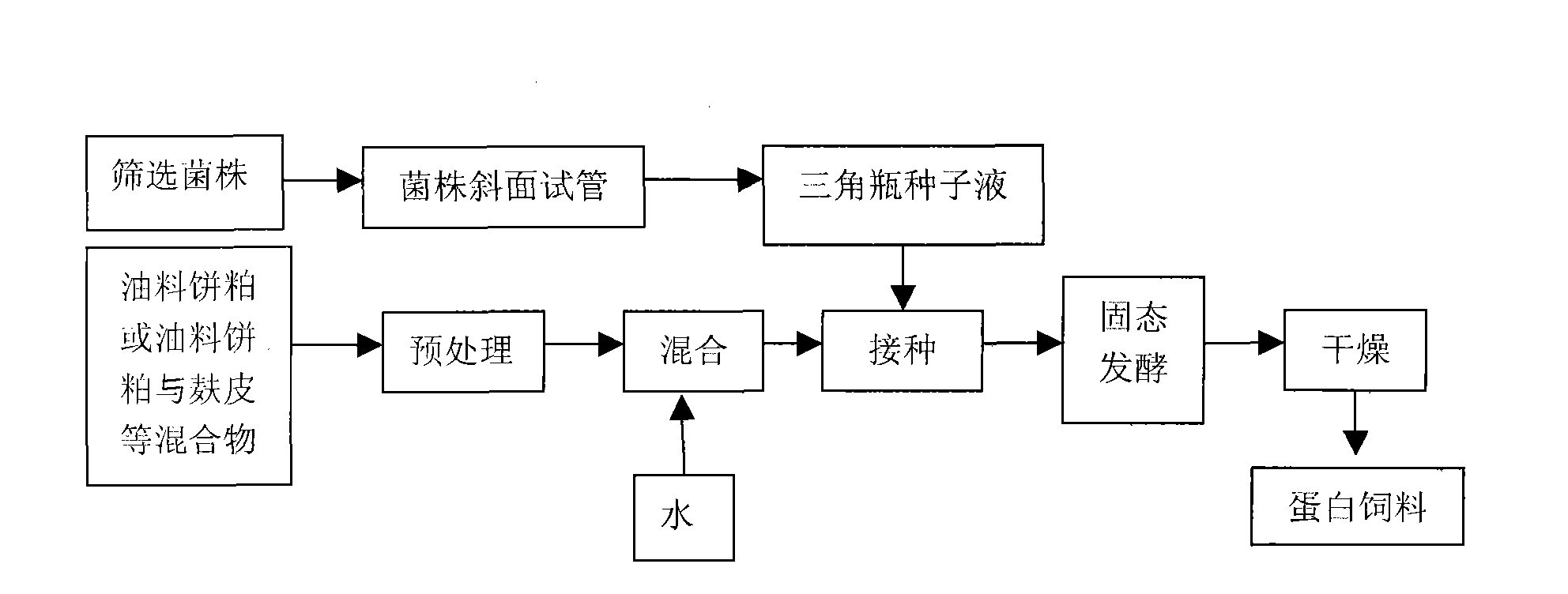

Method used

Image

Examples

Embodiment 1

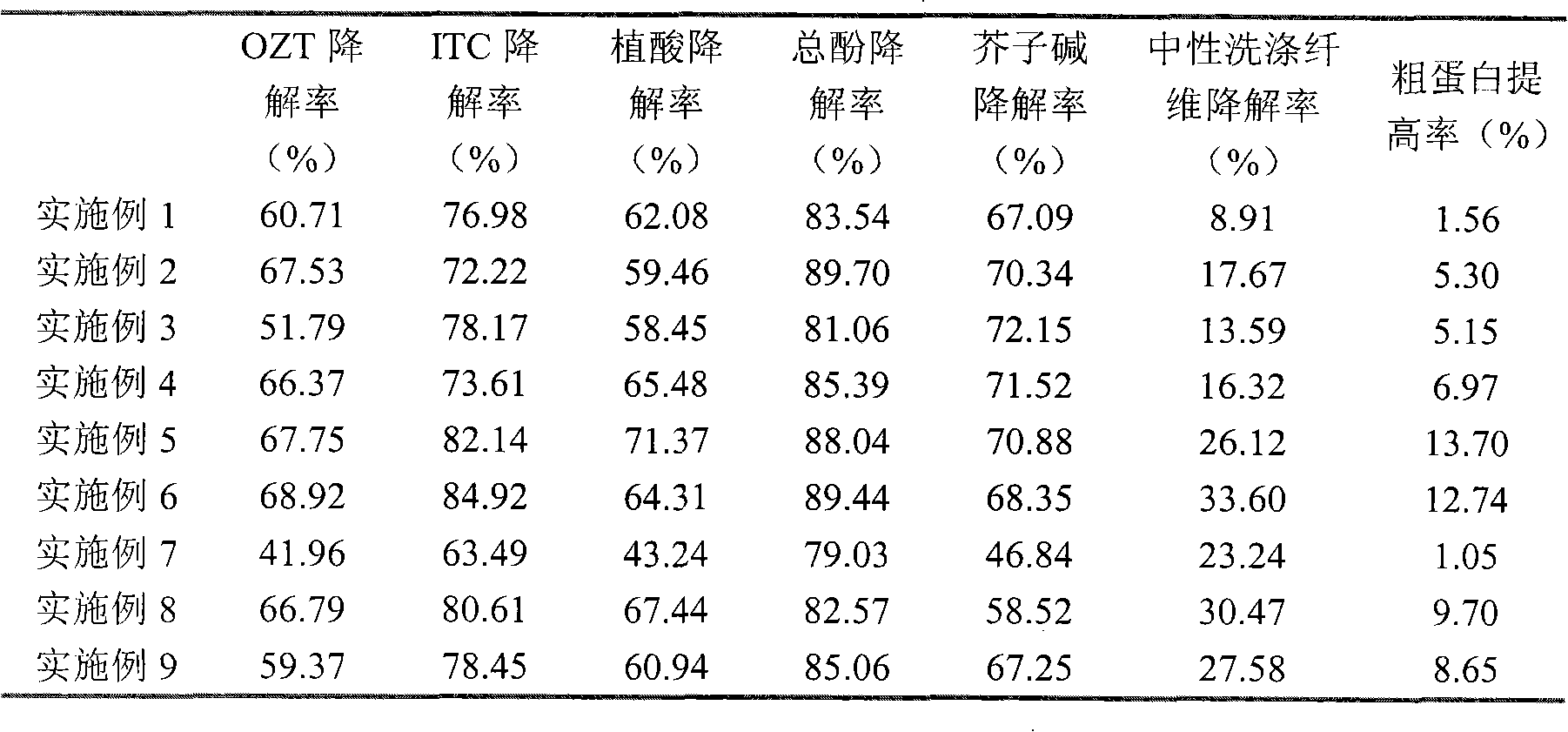

[0023] The crushed rapeseed cake was sterilized under high temperature and high pressure, and treated at 105°C for 10 minutes. Bacillus subtilis B 3 Insert the inoculation amount of 5% (w / w) on the rapeseed meal solid-state fermentation medium (rapeseed meal 60% (w / w), water content 40% (w / w)), and stand at 35°C Fermentation 72h. The fermented base material was dried at 50°C to obtain a protein feed product, and the content of various anti-nutritional factors and nutritional components of the product was measured at the same time. The results are shown in Table 2.

Embodiment 2

[0025] The crushed rapeseed cake was sterilized under high temperature and high pressure, and treated at 105°C for 10 minutes. Bacillus subtilis B 3 , Bacillus natto N 1 and Saccharomyces cerevisiae R 1 With an inoculation ratio of 1:1:1 by weight, a total inoculum of 5% (w / w) was inserted into the rapeseed meal solid-state fermentation medium (60% (w / w) of rapeseed meal, 40% water content (w / w)) and leave to ferment at 35°C for 72h. The fermented base material was dried at 50°C to obtain a protein feed product, and the contents of various anti-nutritional factors and nutritional components of the product were measured at the same time, and the results are shown in Table 2.

Embodiment 3

[0027] The crushed rapeseed cake was sterilized under high temperature and high pressure, and treated at 105°C for 10 minutes. Bacillus licheniformis D 2 , Bacillus natto N 1 and Pichia P 2 With an inoculation ratio of 1:1:1 by weight, a total inoculum of 5% (w / w) was inserted into the rapeseed meal solid-state fermentation medium (60% (w / w) of rapeseed meal, 40% water content (w / w)) and leave to ferment at 35°C for 72h. The fermented base material was dried at 50°C to obtain a protein feed product, and the contents of various anti-nutritional factors and nutritional components of the product were measured at the same time, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com