Method for preparing reducing sugar by catalyzing hydrocellulose

A technology for catalytic hydrolysis and cellulose, applied in sugar production, monosaccharide, chemical recovery, etc., can solve the problems of non-green, high equipment requirements, etc., and achieve the effect of stable performance and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

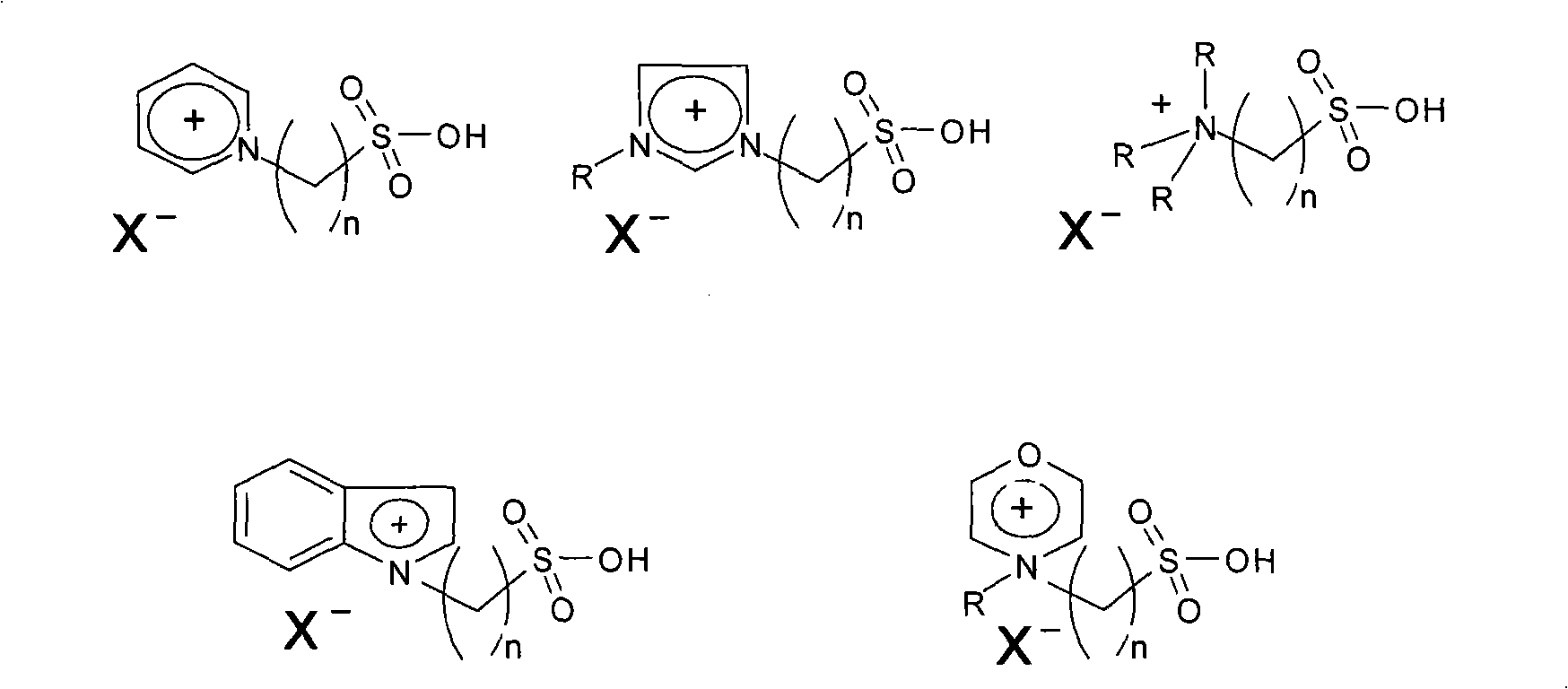

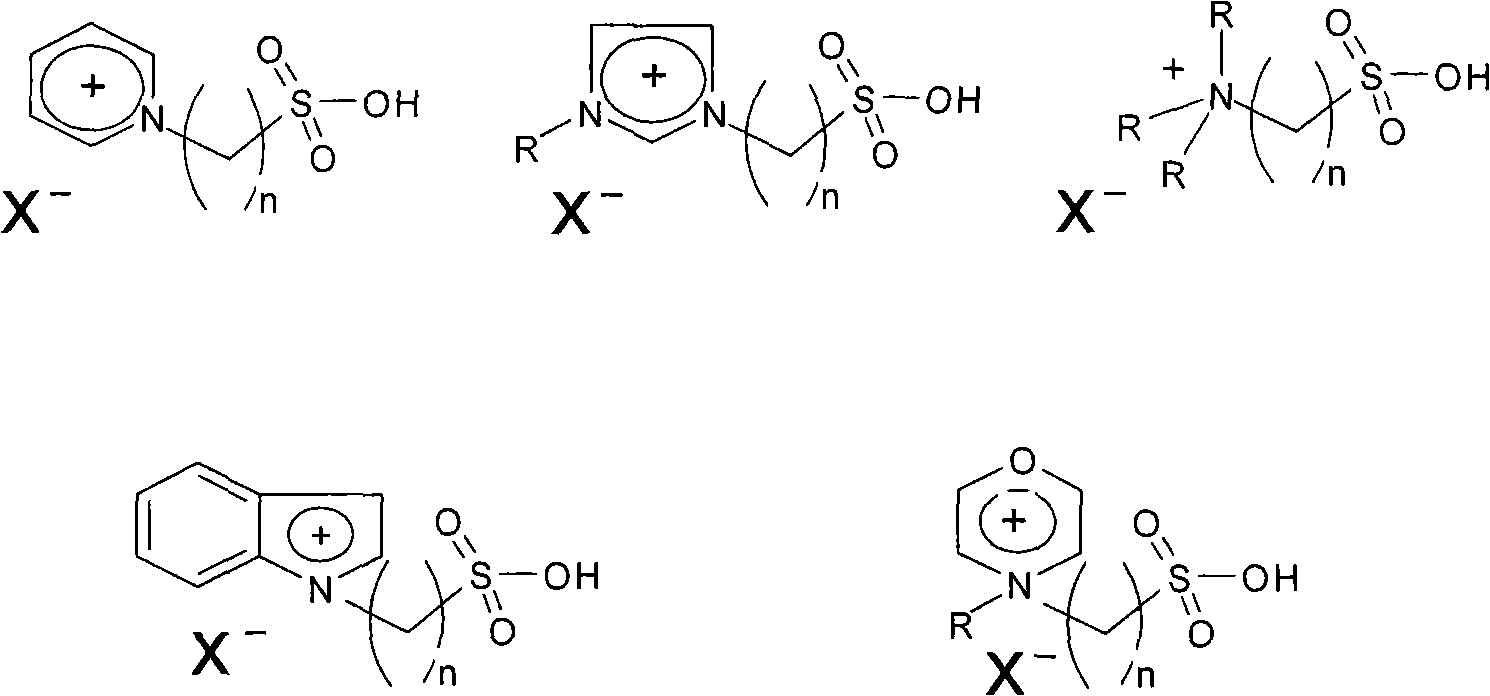

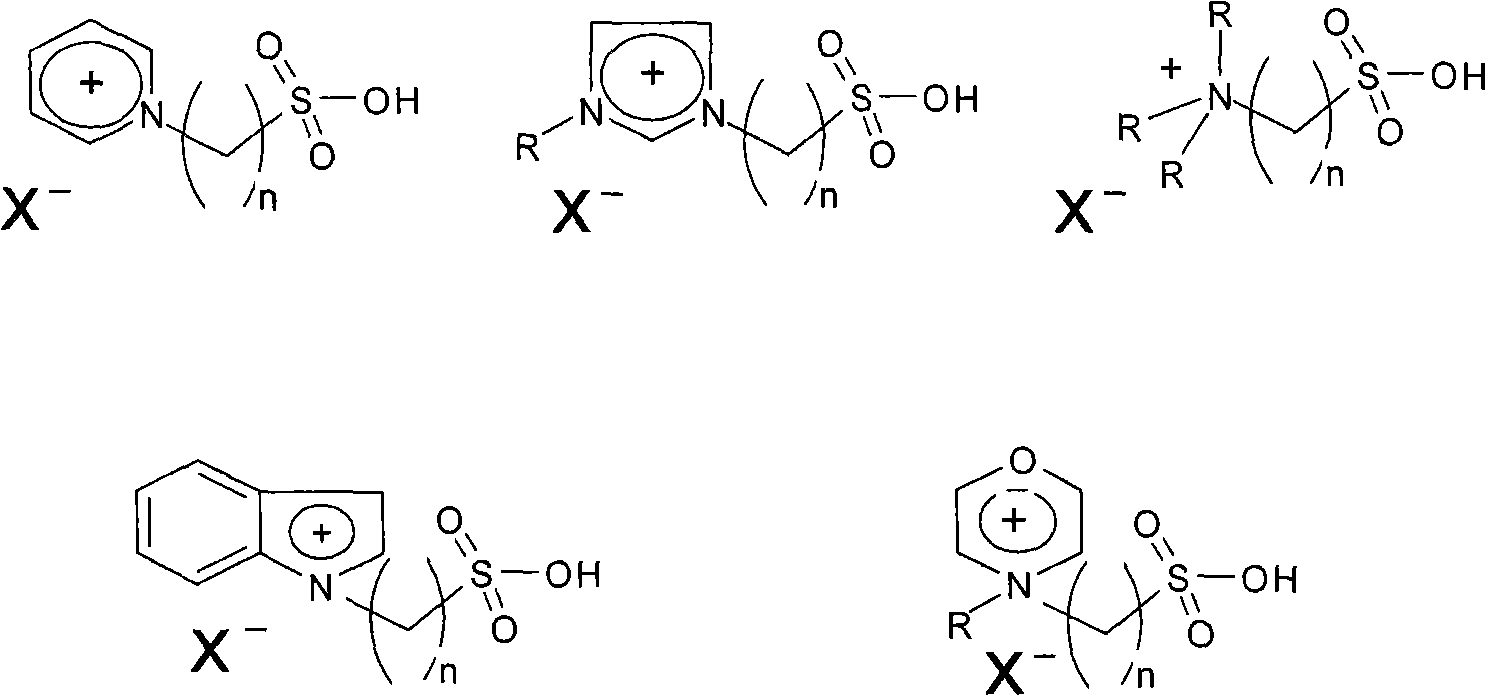

Method used

Image

Examples

Embodiment 1

[0033] In a three-neck flask equipped with a thermometer and a magnetic stirrer, add 4 g of ionic liquid [C 4 mim] C1, heated to 100°C in an oil bath to dissolve. Then add 0.32 g of cellulose to make a uniform and transparent cellulose solution. 0.06 g of water and 0.32 g of acid-functionalized ionic liquid 1-methyl-3-(3-sulfopropyl)imidazolium bisulfate were added to the cellulose solution. React at 100°C for 2-4 hours. After the reaction is completed, water is added and filtered, and the filtrate is passed through an ion exchange resin column to separate the reducing sugar and the ionic liquid. The cellulose conversion rate was 81.3%. The yield of reducing sugar was 79.6%.

Embodiment 2

[0035] In a three-neck flask equipped with a thermometer and a magnetic stirrer, add 4 g of ionic liquid [C 4 mim]C1, microwave heating to 100 ℃ to dissolve. Then add 0.80 g of cellulose to make a uniform and transparent cellulose solution. 0.20 g of water and 0.80 g of acid-functionalized ionic liquid 1-methyl-3-(3-sulfopropyl)imidazolium bisulfate were added to the cellulose solution. React under microwave heating conditions for 10-15 minutes. After the reaction is completed, water is added and filtered, and the filtrate is passed through an ion exchange resin column to separate the reducing sugar and the ionic liquid. The cellulose conversion rate was 89.2%. The yield of reducing sugar was 85.6%.

Embodiment 3

[0037] In a three-neck flask equipped with a thermometer and a magnetic stirrer, add 8 grams of ionic liquid [C 4 mim] C1, heated to 100°C in an oil bath to dissolve. Then add 0.60 g of cellulose to make a uniform and transparent cellulose solution. 0.12 g of water and 0.60 g of acid-functionalized ionic liquid 1-methyl-1-(3-sulfopropyl)morpholine hydrogensulfate were added to the cellulose solution. React at 100°C for 6-8 hours. After the reaction is completed, water is added and filtered, and the filtrate is passed through an ion exchange resin column to separate the reducing sugar and the ionic liquid. The cellulose conversion rate was 79.4%. The yield of reducing sugar was 74.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com