Cigarette perfume solvent and preparation method thereof

A technology for tobacco flavor and solvent, which is applied in the field of cigarette additive preparation, can solve the problems of poor coordination of tobacco aroma, high irritation, and no occurrence, and achieve the effects of obvious sweetness, alleviation of irritation, and enhancement of tobacco flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 10 kg of Yunnan tobacco leaf tobacco powder raw material, add water 13 times the mass of tobacco powder, heat to 96°C-100°C, reflux extraction for 2 hours, and then filter. Add 200 grams of malic acid while it is hot (liquid temperature 50°C to 60°C), then add 20 kg of sucrose, and stir to fully dissolve. When the temperature of the crude filtrate dropped to 35°C, inoculate 50 grams of Saccharomyces cerevisiae. The suitable temperature is kept at 20-30°C, and the sealed fermentation ends after 10 days. Stir and heat at normal pressure to 80°C to 85°C for distillation, adjust the alcohol content of the distillate to 55° to 57° (20°C, V / V), and obtain tobacco flavor solvent sample 1.

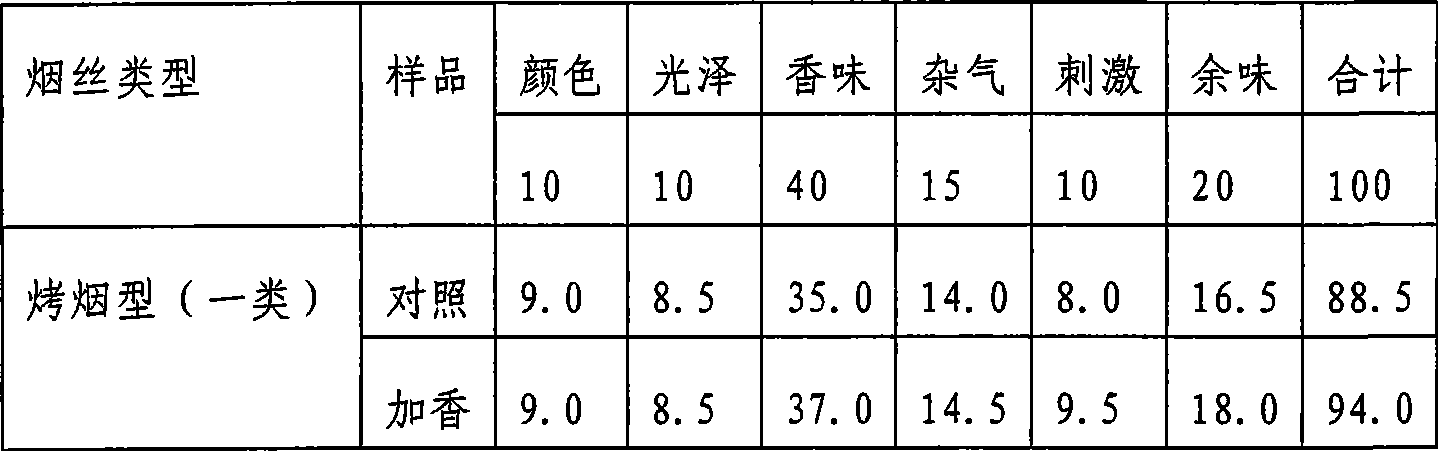

[0025] Sample 1 was applied to the flue-cured cigarette formula. Using edible alcohol as a control, use the contrast method to compare the aroma and taste of smoking. Professional smokers will conduct sensory evaluation. The results are shown in Table 1:

[0026] Table 1:

[0027]...

Embodiment 2

[0033] Weigh 10 kg raw material of Zimbabwean tobacco leaf fragments, add water 10 times the mass of the tobacco leaf fragments, heat to 96°C-100°C, reflux extraction for 2 hours and then filter. Add 300 grams of tartaric acid while it is hot (liquid temperature 50°C to 60°C), then add 20 kg of fructose, and stir to fully dissolve. When the temperature of the crude filtrate dropped to 35°C, inoculate 50 grams of wine yeast. The suitable temperature is kept at 20-30°C, and the sealed fermentation ends after 14 days. Stir and heat at normal pressure to 80°C to 85°C for distillation, adjust the alcohol content of the distillate to 55° to 57° (20°C, V / V), and obtain tobacco flavor solvent sample 2.

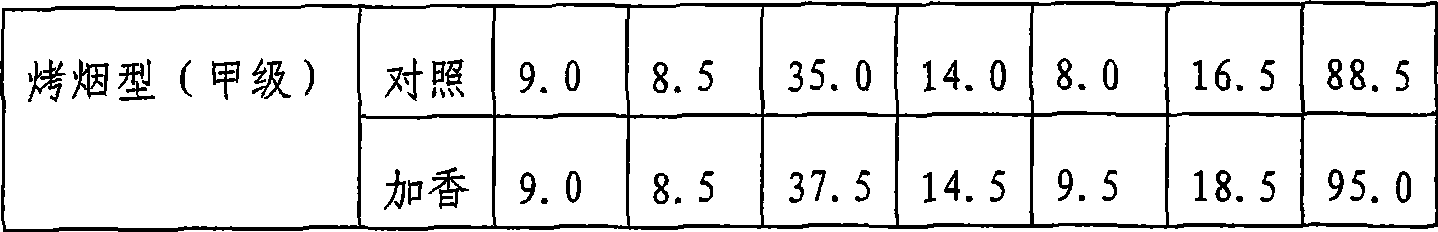

[0034] Sample 2 was applied to the flue-cured cigarette formula. Using edible alcohol as a control, use the contrast method to compare the aroma and taste of smoking, and conduct sensory evaluation by professional smokers. The results are shown in Table 3:

[0035] table 3:

[003...

Embodiment 3

[0043] Weigh 10 kg of raw materials of Brazilian tobacco leaf fragments, add water 12 times the mass of the tobacco leaf fragments and 5% edible alcohol, heat to 96° C. to 100° C., reflux extraction for 1 hour and then filter. Add 100 grams of malic acid and 100 grams of tartaric acid while it is hot (liquid temperature 50°C to 60°C), then add 10 kg of sucrose and 10 kg of fructose as raw materials, and stir to fully dissolve. When the temperature of the crude filtrate dropped to 35°C, inoculate 50 grams of grape yeast. The suitable temperature is kept at 20-30°C, and the sealed fermentation ends after 15 days. Stir and heat at normal pressure to 80°C to 85°C for distillation, adjust the alcohol content of the distillate to 70° to 75° (20°C, V / V), and obtain tobacco flavor solvent sample 3.

[0044] Sample 3 was applied to the flue-cured cigarette formula. Using edible alcohol as a control, compare the aroma and taste of smoking with the comparative method, and conduct senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com