Cold extruding and forming process of lower oil cylinder of manual porter

A forming process, cold extrusion technology, applied in the direction of metal material coating process, etc., can solve the problems of poor quality consistency, labor, and material waste, and achieve high production efficiency, high product strength, and material structure. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

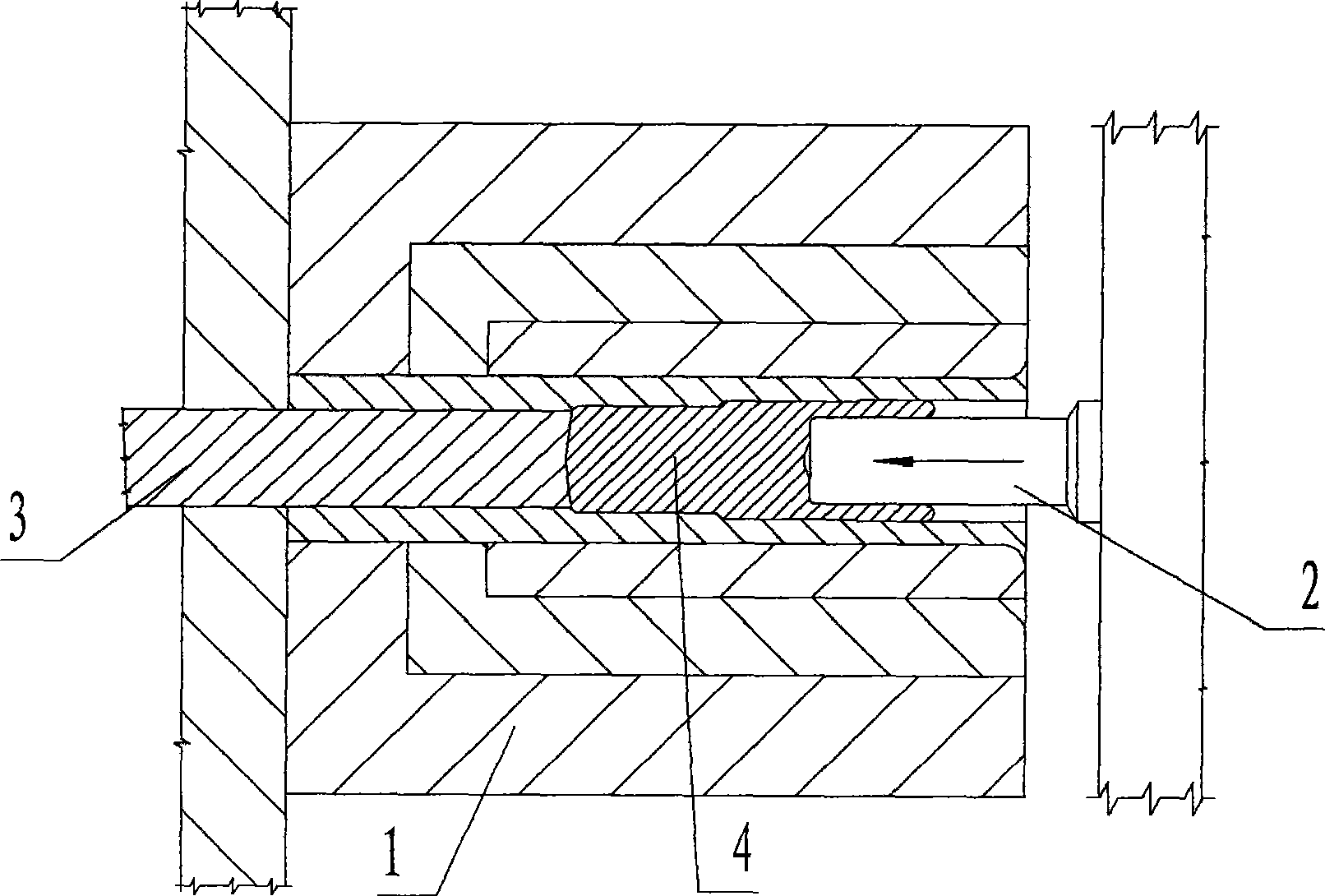

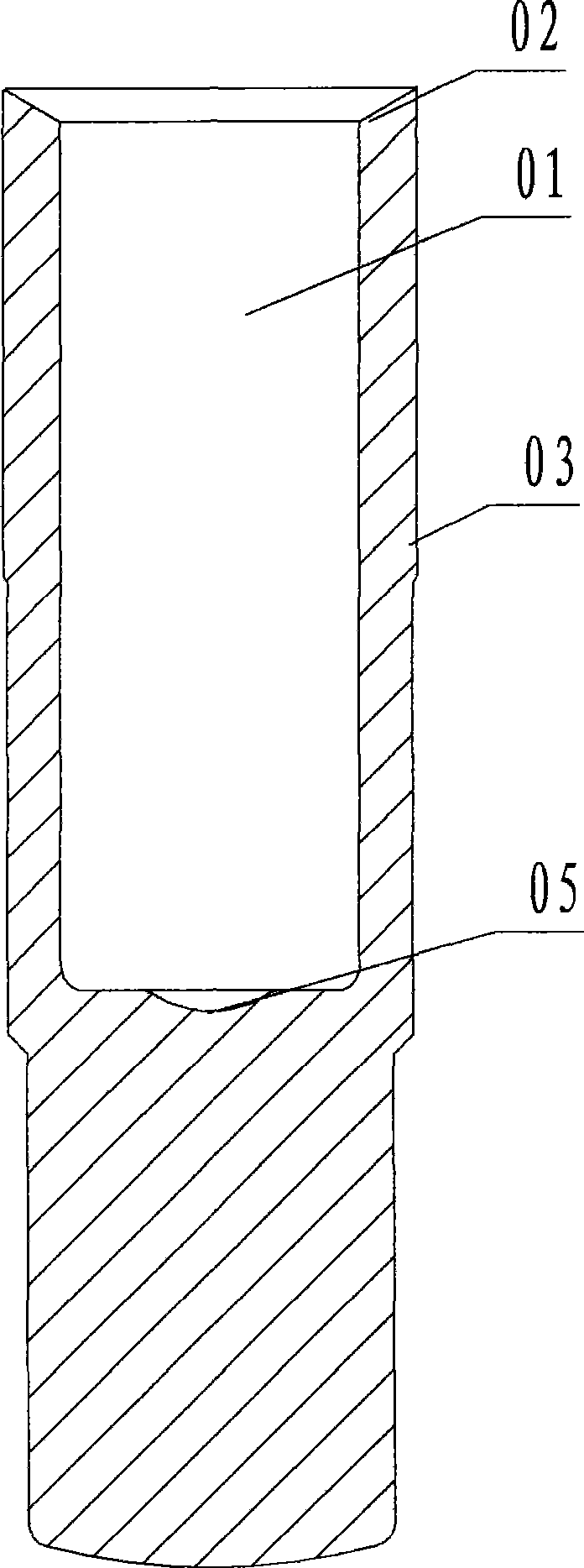

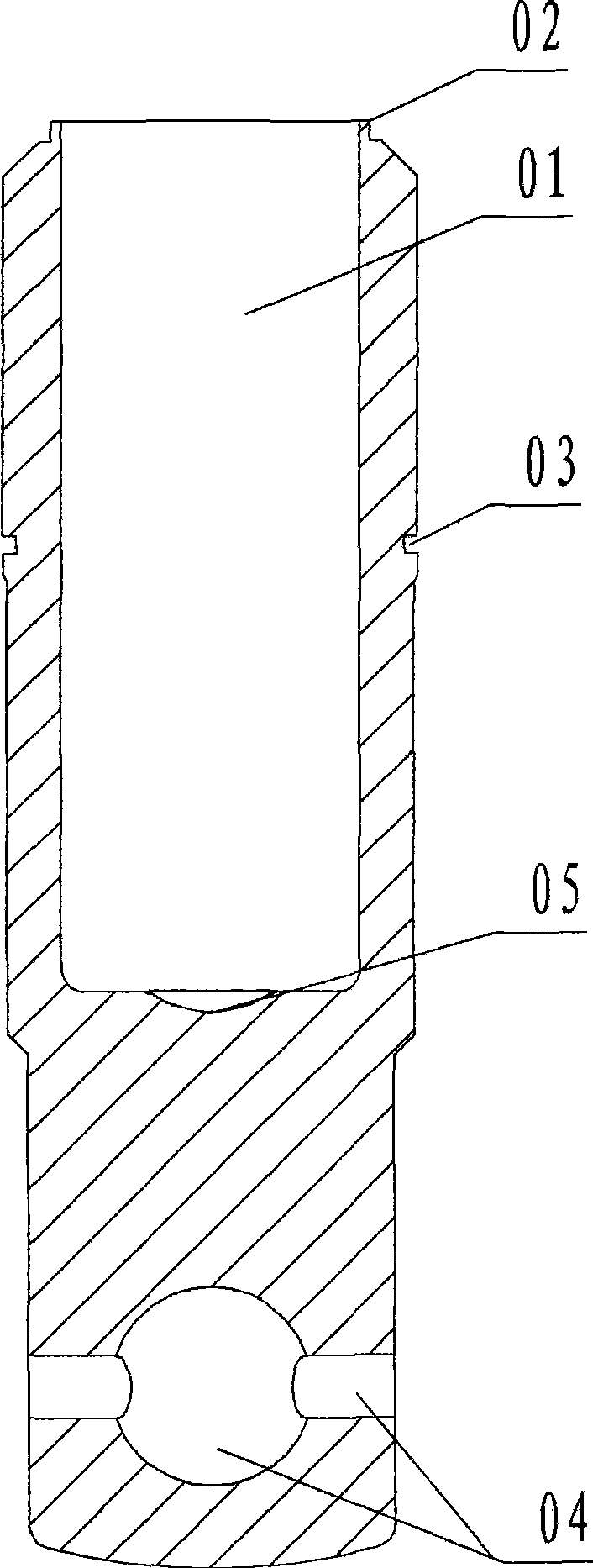

[0017] refer to figure 1 , figure 2 , image 3 , the cold extrusion molding process of the oil cylinder under the manual pallet truck of the present invention includes phosphating and cold extrusion, wherein: the phosphating is to immerse the low-carbon steel billet after degreasing and rust removal at a medium temperature of 50-75°C In the phosphating solution, the phosphating treatment time is 10-15 minutes, and the thickness of the phosphating film formed is greater than 10g / m2 per unit area. 2 , and then use zinc stearate, sodium stearate and other soapy materials to coat the surface layer and make it full of the chemical treatment process of phosphating saponification in the pores of the phosphating film; The low-carbon steel billet is placed in the composite die 1 with a three-layer prestressed structure composed of high-speed steel, high-carbon and high-chromium alloy tool steel, which is made of cemented carbide as the inner layer, and the cemented carbide punch 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com