Methanol gasoline additive and preparation method thereof and methanol gasoline

A technology of methanol gasoline and additives, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc. It can solve the problems of air lock, high cost, and large amount of additives, and achieve the prevention of oxidation and corrosion, easy cold start, stable mutual solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

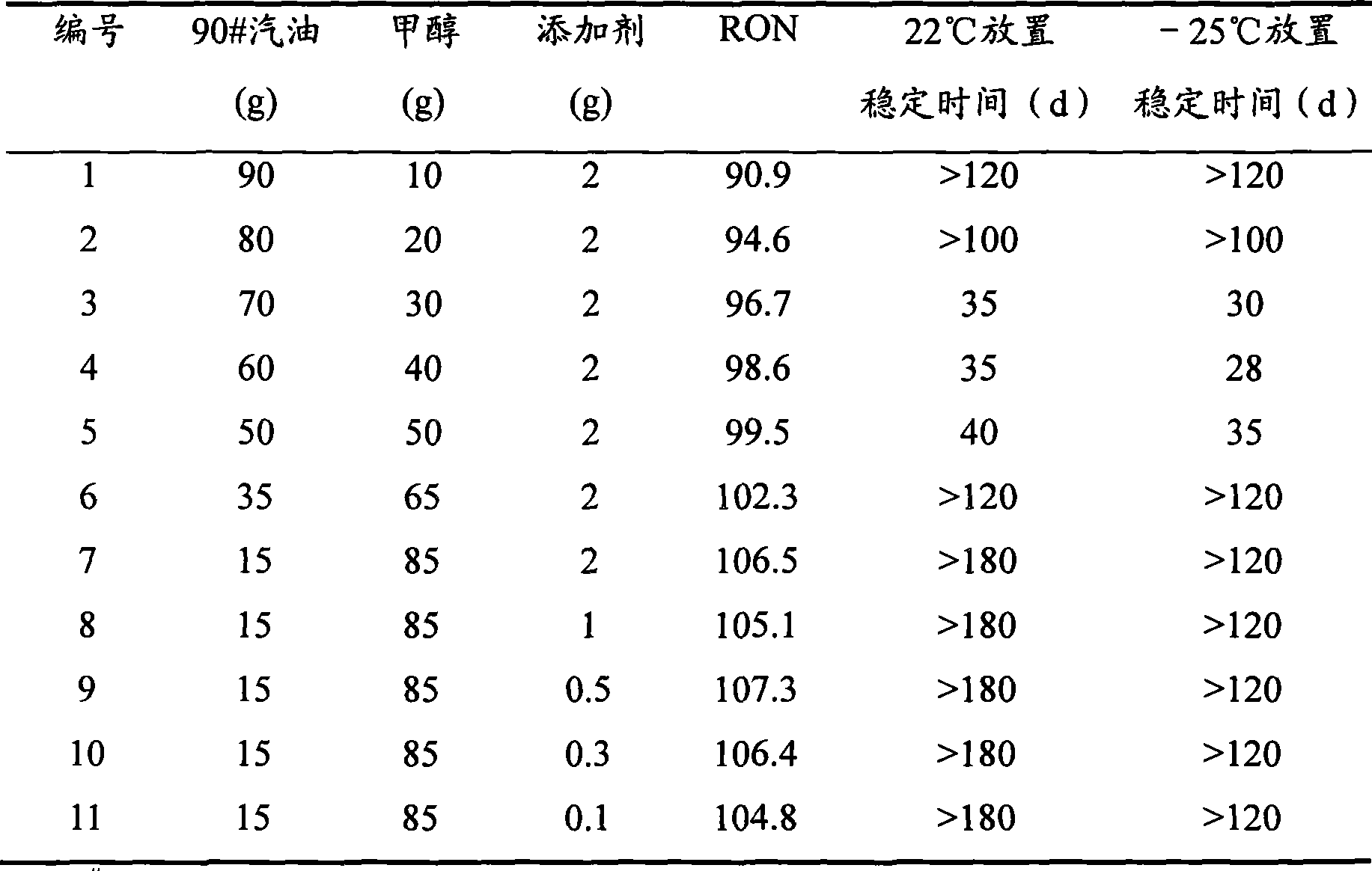

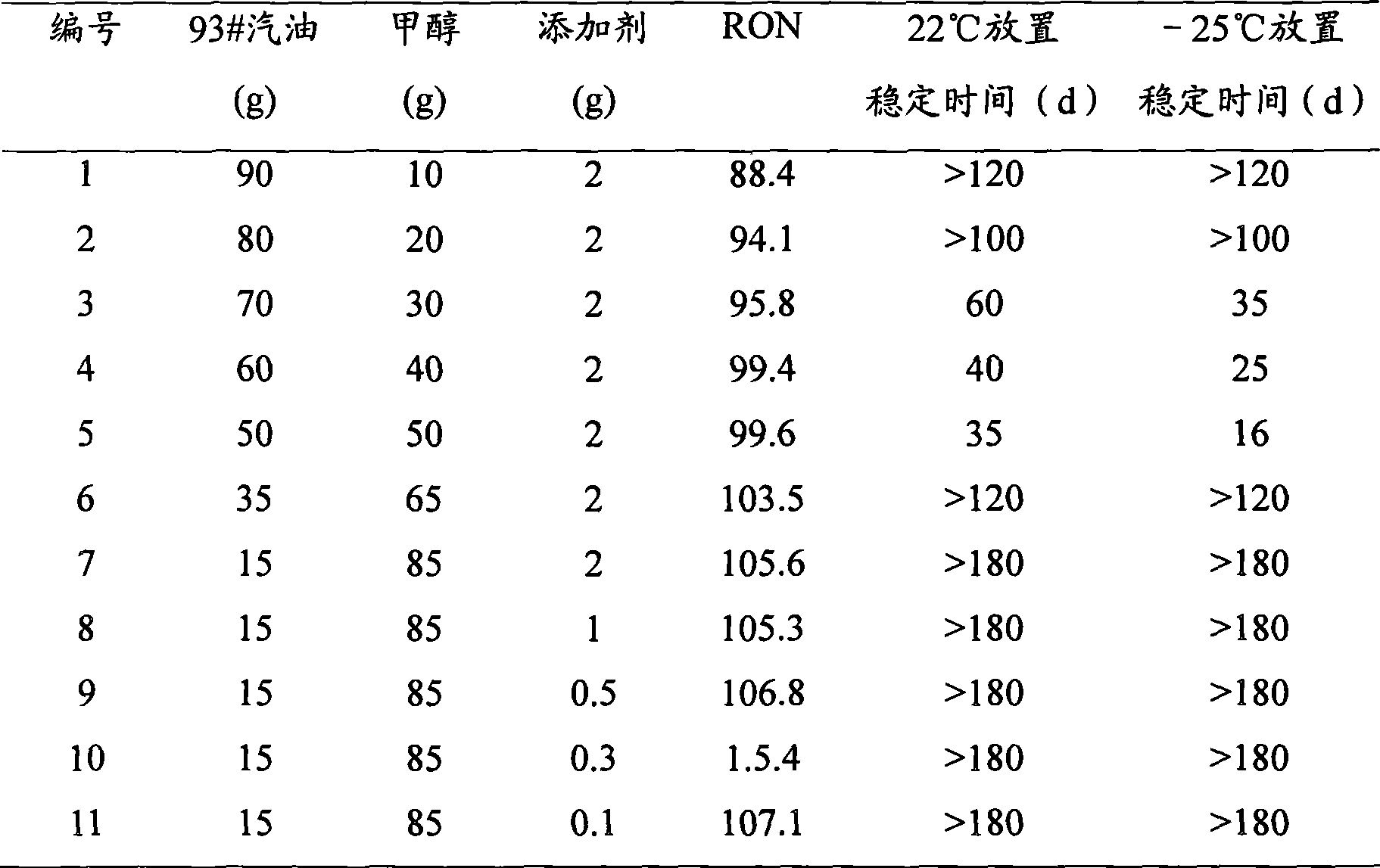

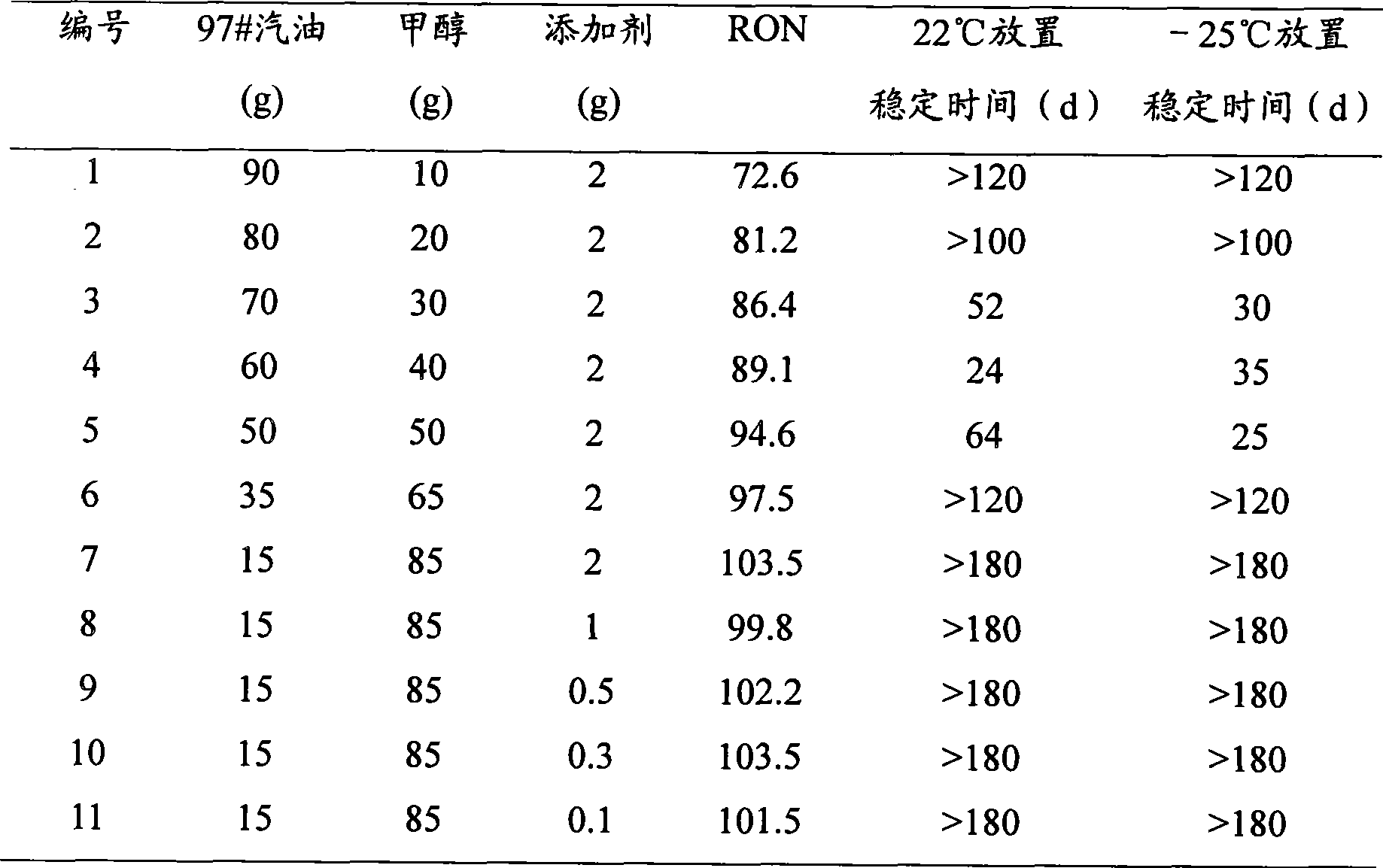

Examples

preparation example Construction

[0038] (The preparation method of methanol gasoline additive)

[0039] The methanol gasoline additive of the present invention is obtained through the following process. Weigh the required amount of each component of the above-mentioned methanol gasoline additive, add anti-oxidation corrosion agent, detergent and dispersant, combustion-promoting anti-explosion agent, coloring agent and mutual solvent into the reactor under stirring, and fully mix. After the addition, the temperature is raised to 20-80°C, preferably 45-50°C, stirred for 0.5-10 hours, cooled naturally, and the specific gravity is 1.05-1.15g / ml. Finally, a yellow or red-yellow transparent solution is obtained, free from water-soluble acid and alkali, and kept in airtight storage. In addition, as long as the reactor of the present invention is equipped with a stirring device, a condenser, and a temperature measuring device, any reactor can be used.

[0040]The methanol gasoline additive obtained according to the...

Embodiment 1

[0052] In the reaction kettle equipped with a thermometer, a high-speed shear mixer and a condenser, add 2.0 kg of ethylene glycol, start stirring, and add the following substances:

[0053] 2,6-di-tert-butyl-p-cresol 200g

[0054] N,N'-diisopropyl-p-phenylenediamine 25g

[0055] T154 polyisobutylene succinimide 400g

[0056] Methylcyclopentadiene Manganese Tricarbonyl 100g

[0057] n-Butanol 1.4kg

[0058] Sudan Red 50g

[0059] After the addition is complete, heat to 45-50°C, stir for 2 hours, and cool naturally to obtain a yellow or reddish-yellow transparent solution, which is sealed and stored.

Embodiment 2

[0061] In the reaction kettle equipped with a thermometer, a high-speed shear mixer and a condenser, add 2.0 kg of ethylene glycol, start stirring, and add the following substances:

[0062] 2,6-di-tert-butyl-p-cresol 100g

[0063] N,N'-diisopropyl-p-phenylenediamine 15g

[0064] T154 polyisobutylene succinimide 500g

[0065] Methylcyclopentadiene Manganese Tricarbonyl 50g

[0066] Isopropanol 1.3kg

[0067] Sudan Red 50g

[0068] After the addition is complete, heat to 45-50°C, stir for 2 hours, and cool naturally to obtain a yellow or reddish-yellow transparent solution, which is sealed and stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com