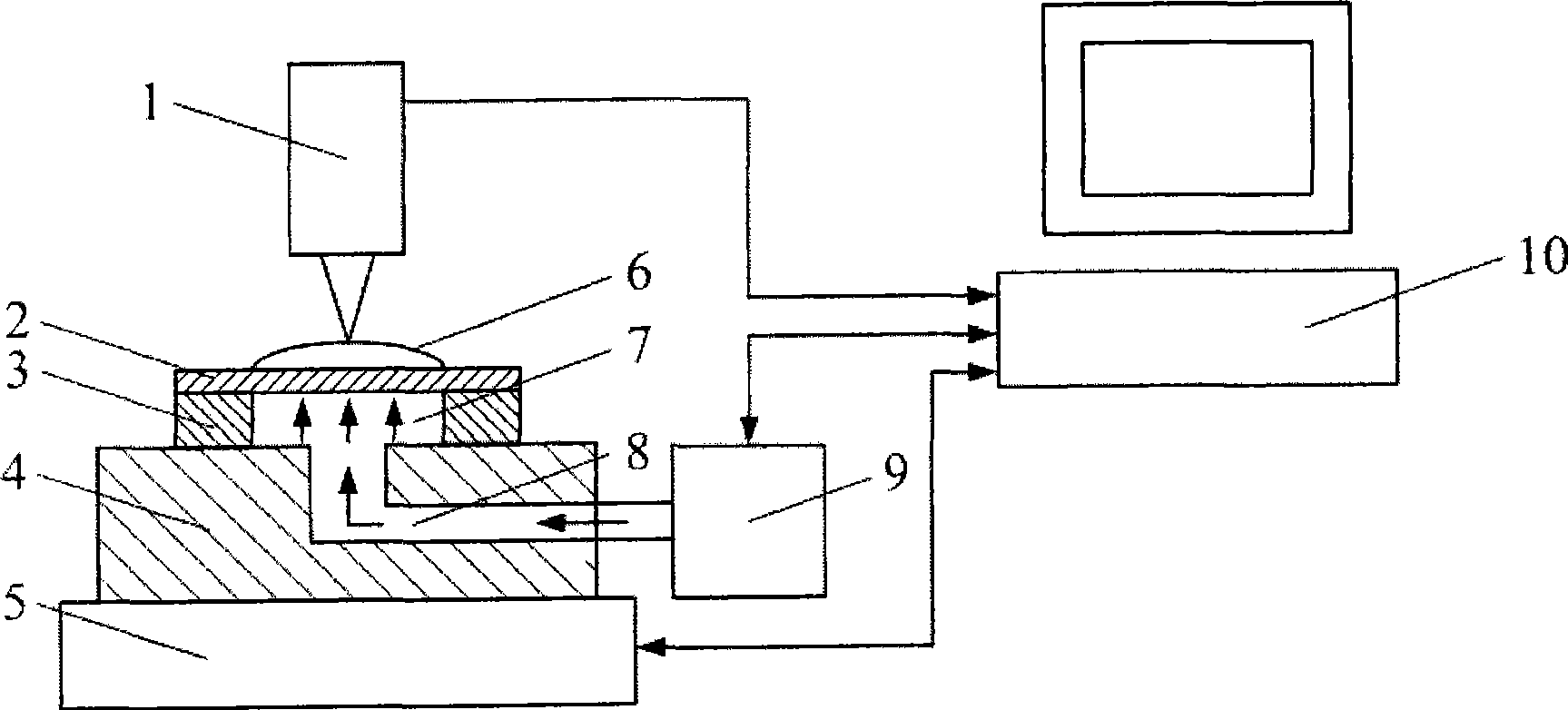

Method for testing mechanical property and reliability of thin film material of micro-electromechanical system (MEMS) and device thereof

A technology of micro-electromechanical systems and thin-film materials, applied in the field of micro-electromechanical systems, can solve problems such as the damage and influence of the measured thin film cannot be eliminated, the sample clamping and alignment difficulties, and the preparation process are complicated, so as to achieve high test efficiency and simple test. , the effect of simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

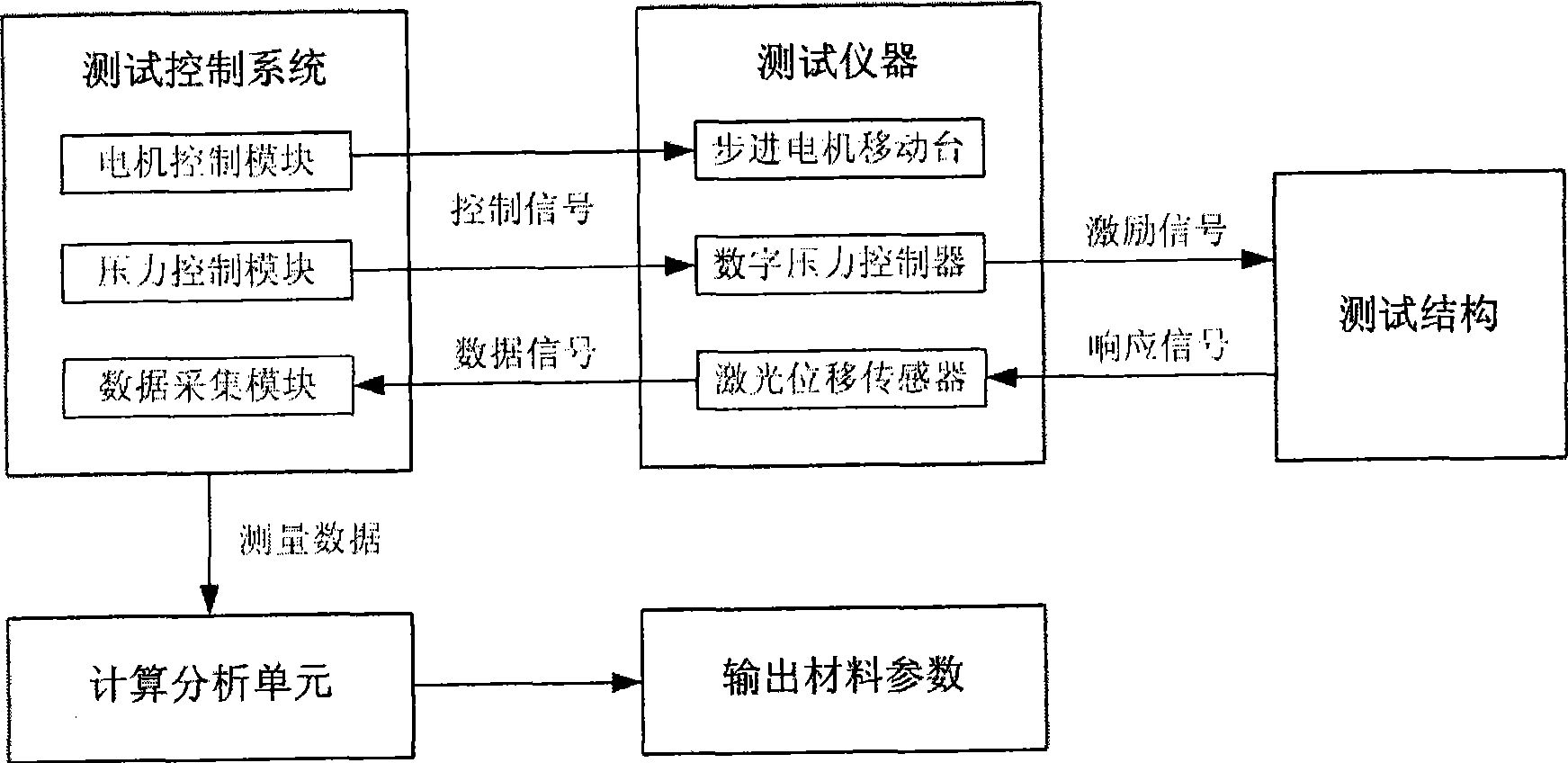

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

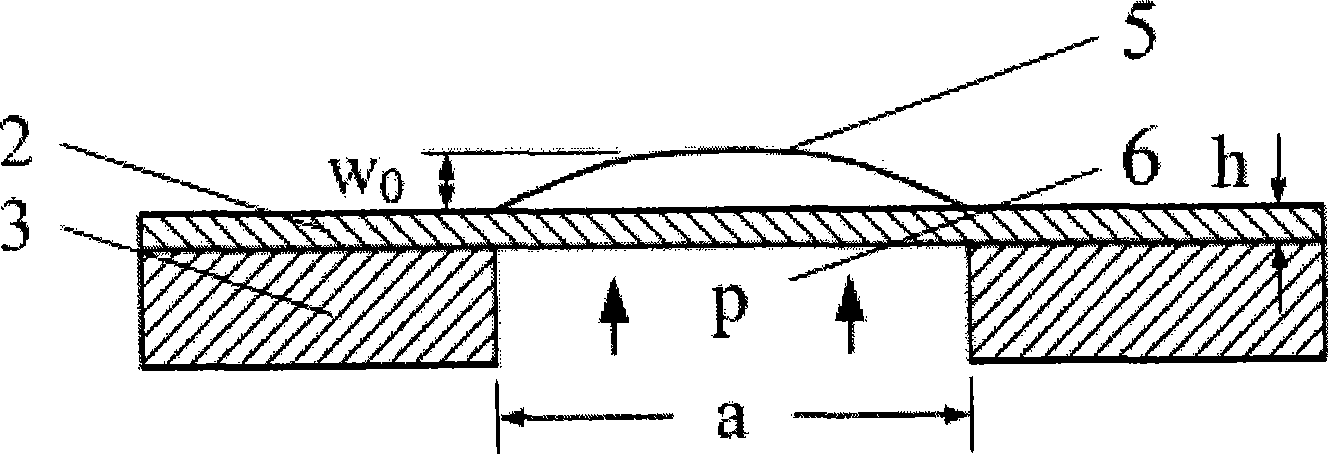

[0059] The preparation steps of the above-mentioned test structure are as follows: the measured material thin film 2 is deposited on the substrate 3, and the deposition process of the measured material thin film 2 can be traditional chemical vapor deposition (CVD), physical vapor deposition (PVD) Wait. Then, a thin film is deposited on the back of the substrate 3, and the thin film is used as a mask when etching the substrate 3, and the thin film is subjected to photolithography and dry etching to form pattern windows. The substrate 3 with the mask pattern on the back is placed in the wet etchant, and the substrate 3 exposed in the pattern window of the mask layer film is etched away to form a cavity 7, so that the measured material film 2 is partially The area forms a suspended membrane 6 .

[0060] The shape of the suspended membrane 6 is one of rectangle, square or circle, and an array with multiple suspended membranes 6 can be prepared on the same substrate 3 at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com