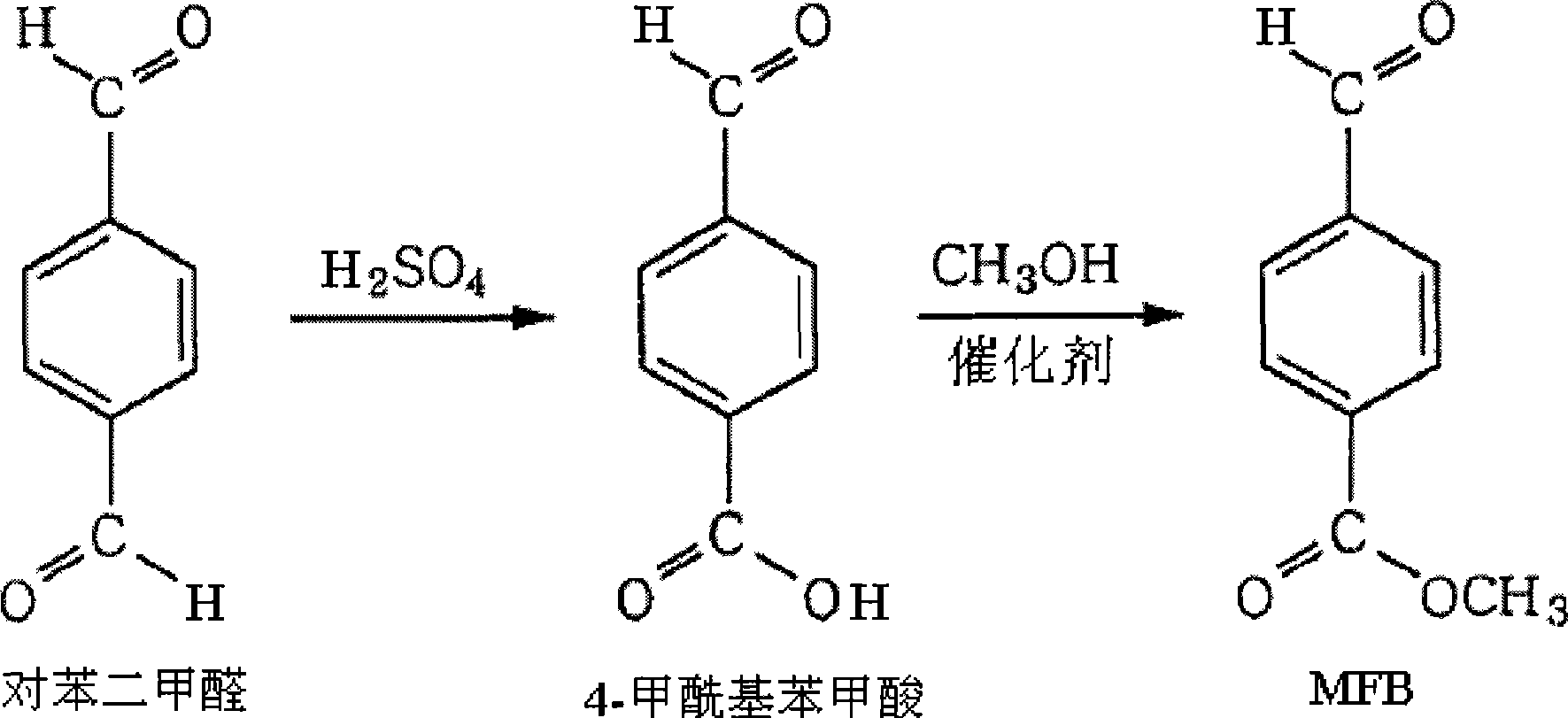

The process of isolating methyl-4-formylbenzoate and dimethylterephtalate

A technology of methyl formylbenzoate and dimethyl terephthalate, which is applied in the field of separation of methyl 4-formylbenzoate and dimethyl terephthalate, which can solve the disadvantages of worker safety and the high cost of MFB production , environmental problems and other issues, to achieve the effect of alleviating economic and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

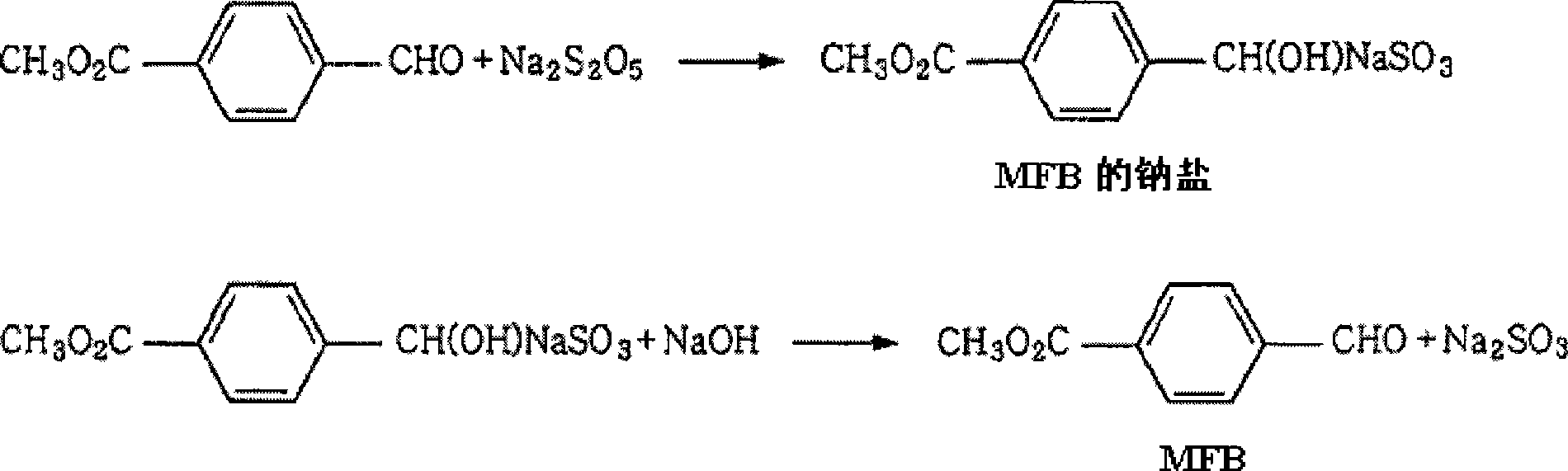

Problems solved by technology

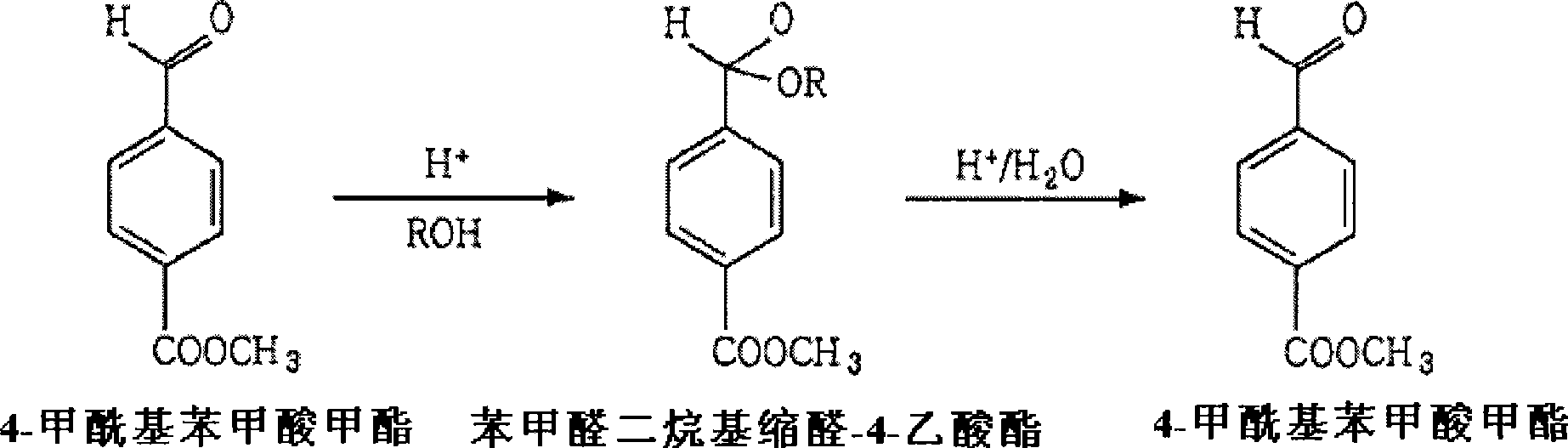

Method used

Image

Examples

Embodiment 1

[0038] 200 parts by weight of methanol were added to 100 parts by weight of a mixture containing about 63% by weight of MFB, about 30% by weight of DMT, about 6% by weight of MPT, about 1% by weight of MBZ and traces of impurities, and the mixture Is a by-product in the process of preparing DMT. The methanol solution was stirred at 25°C for 0.5 hours. After the stirring was completed, only DMT remained as a solid, and the stirred solution was filtered to recover DMT as a solid. The solid DMT was washed with methanol, and the weight of DMT thus obtained was 27.4 g, and the purity was 99.4%.

[0039] To the obtained filtrate was added 0.2 parts by weight of hydrochloric acid (HCl), and the solution was stirred for 2 hours to convert MFB into benzaldehydedimethylacetal-4-acetate. When the reaction product converted to benzaldehyde dimethylacetal-4-acetate was kept at -2°C, the residual DMT was precipitated as a solid. The reaction product was filtered at -2°C to recover the re...

Embodiment 2

[0042] 200 parts by weight of ethanol were added to 100 parts by weight of a mixture containing about 63% by weight of MFB, about 30% by weight of DMT, about 6% by weight of MPT, about 1% by weight of MBZ and traces of impurities, and the mixture Is a by-product in the process of preparing DMT. The ethanol solution was stirred at 25°C for 0.5 hours. After the stirring was completed, only DMT remained as a solid, and the stirred solution was filtered to recover DMT as a solid. The solid DMT was washed with ethanol, and the weight of DMT thus obtained was 25.1 g, and the purity was 99.6%.

[0043] To the obtained filtrate was added 0.2 parts by weight of hydrochloric acid (HCl), and the solution was stirred for 2 hours to convert MFB into benzaldehyde dimethylacetal-4-acetate. When the reaction product converted to benzaldehyde dimethylacetal-4-acetate was kept at -2°C, the residual DMT was precipitated as a solid. The reaction product was filtered at -2°C to recover residual...

Embodiment 3

[0046] MFB was recovered in the same manner as in Example 1, except that the heptane was replaced with the same amount of Exelsol 670 (Korean SK Company). In this case, the recovered DMT had a purity of 99.4% and weighed 29.8 g, and the recovered MFB had a purity of 98.8% and weighed 39.9 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com