Method for preparing bonding superfine Al welding wire

A manufacturing method and welding wire technology, which can be applied to manufacturing tools, welding media, welding equipment, etc., can solve the problems of increasing the number of broken wires, reducing work efficiency, etc., so as to reduce the number of broken ends, improve production efficiency, and eliminate surface defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: A kind of manufacturing method of bonding Al welding wire, the steps are as follows:

[0014] First stretch the Al-1% Si alloy wire billet to Φ1.0mm with an alloy die, and then treat it with 20% NaOH solution at 60°C to remove wire drawing lubricating oil stains on the wire surface, then wash it with water, and then enter chemical polishing. Immerse the length of 100-300mm in the tank, rinse with water after chemical polishing, dry with hot air, and finally take it up with a take-up shaft.

[0015] Its operating process is:

[0016] Wire drawing→greasing→water washing→chemical polishing→water washing→hot air drying→collection.

[0017] Wherein, the chemical polishing fluid is formulated by the following components: phosphoric acid (H 3 PO 4 Specific gravity 1.7) 50-90%, nitric acid (HNO 3 Specific gravity 1.5) 5-20%, glacial acetic acid (CH 3 COOH concentrated) 5~30%, copper chloride (CuCl 2 Crystal) 3-50 g / L, phosphoric acid, nitric acid, and glacia...

Embodiment 2

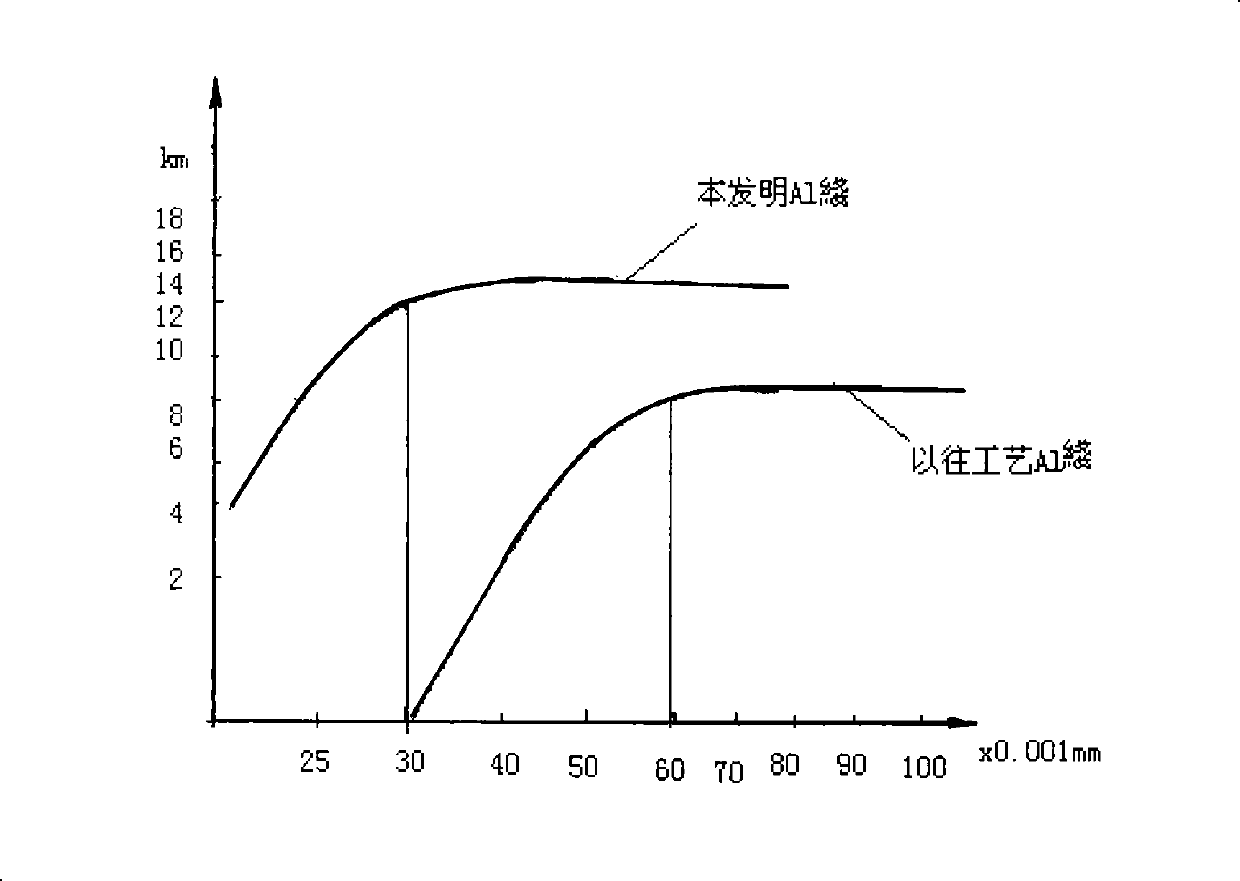

[0019] Embodiment 2: the Al welding wire prepared in embodiment 1 is stretched to 100~25 μ m by the average deformation rate of 7% per pass, and the speed is 150 m / min, and the average single head length of each wire diameter is obtained. Compared with the average single head length of the wire rod of the same size prepared by common process in the prior art, the results are as follows: figure 1 shown.

[0020] Depend on figure 1 Visible, because the present invention has carried out chemical polishing to the Al alloy wire of Φ1.0mm, has eliminated surface defect, makes surface smooth, and has produced extremely thin and uniform oxide film on the surface, has improved lubricity and reduced the number of broken ends, the same The average single end length of the wire of the present invention is long in diameter, and the difference is large especially below Φ60 μm. At the same time, it can also be seen that when the ultra-fine wire is drawn, the transition point (such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com