Noise-reducing and rut-resisting agent and production method thereof

A production method and noise reduction technology, applied in the field of noise reduction and anti-rutting agent, can solve the problem of high noise, and achieve the effects of reducing noise, improving adhesion, and being safe and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

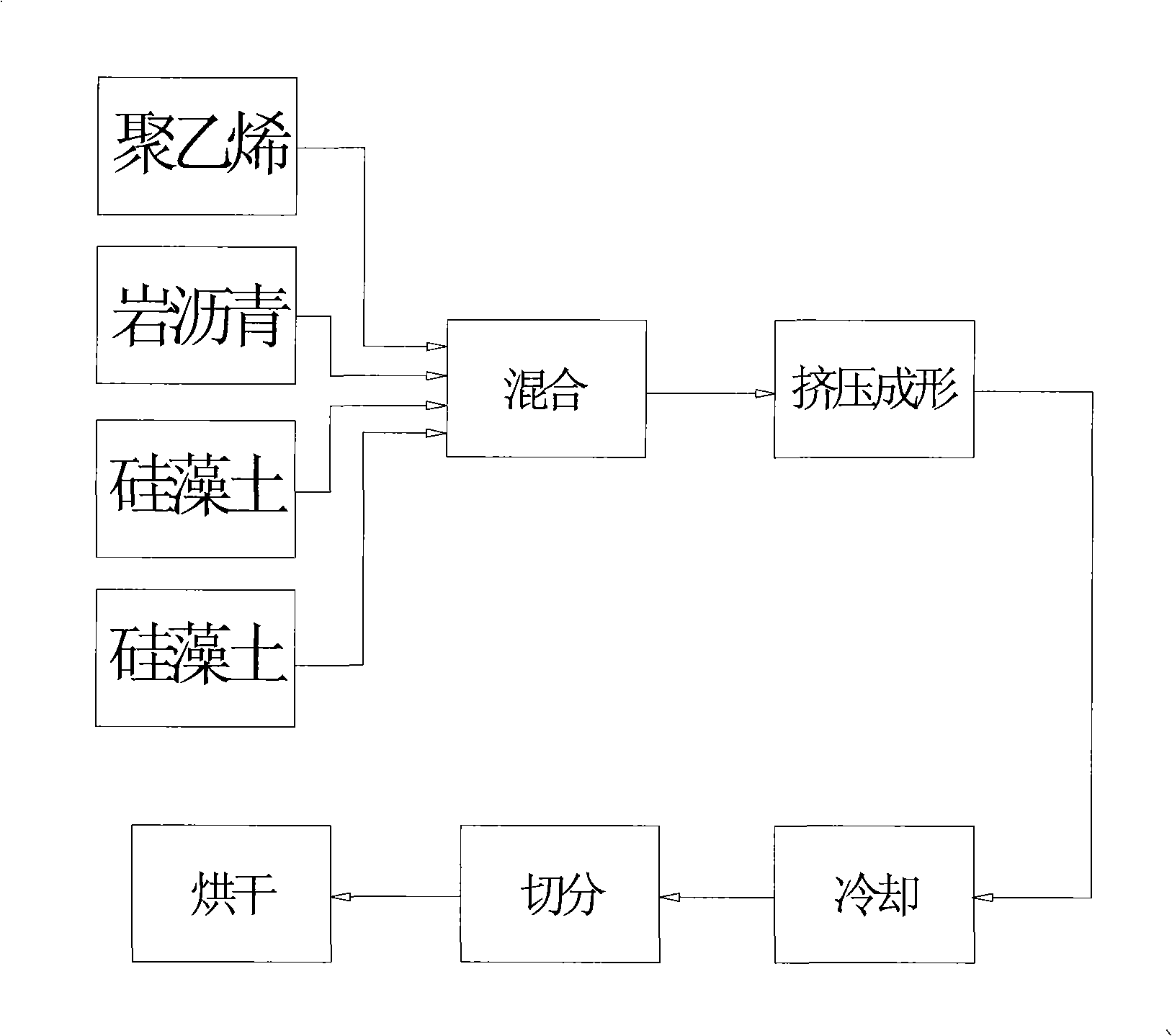

Method used

Image

Examples

Embodiment 1

[0024] First take 5000g of rock asphalt with 400 mesh size, recycle 15000g of polyethylene (RPE, waste film with side length or radial size about 10mm), 20,000g of diatomaceous earth with 400 mesh size and 60,000g of rubber powder, and mix them in the mixer at room temperature. ,Use electronic metering to add to the screw extruder for blending and extrusion (processing and extrusion temperature is 160°C) to form a strip-shaped semi-finished product. Then through water cooling (the water temperature is lower than 20℃), the wheel cutter is divided and granulated (particle size is 3~4mm), and it is dried in a drying device for one hour (temperature 80℃) to obtain the noise reduction of the present invention Finished anti-tracking agent.

Embodiment 2

[0026] First take 10000g of 400 mesh rock asphalt and 25000g of diatomaceous earth of similar particle size, as well as 20000g of low-density polyethylene (LDPE) (with a particle size of less than 1mm), and 65000g of rubber powder of about 60 mesh. Blending and extruding out of the machine (processing and extrusion temperature is 140°C) to form a semi-finished product in strip shape. Then through water cooling (water temperature lower than 20 ℃), wheel cutter slitting and granulation (particle size 3 ~ 4mm), and drying in a drying device for one hour (temperature 80 ℃), that is, the new type of resistance of the present invention is obtained. Finished rutting agent.

Embodiment 3

[0028] The raw materials used rock asphalt 14000g, polyvinyl chloride (PVC) 30,000g, diatomaceous earth 30,000g and rubber powder 70,000g, the particle size is the same or similar to the above-mentioned embodiment, and the process flow and process parameters are the same as in embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com