Method for environment-friendly utilization of copper-nickel-tungsten alloy

A tungsten alloy and waste technology, applied in the field of environmental protection utilization of copper-nickel-tungsten alloy, can solve the problems of difficult treatment, waste liquid discharge pollution, low utilization rate, etc., and achieve the effect of high social and economic benefits and no environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] Follow the steps below:

[0027] 1. In the rotary drum reactor, add copper-nickel-tungsten-containing waste and sodium chloride to the waste acid etching solution containing copper chloride, heat to 80°C, wait until the solution turns dark brown and then detect: Take a sample of 10ml and pour it into 50ml of water to form a white precipitate, and the copper ion content in the supernatant on the precipitate is detected <0.01%. At this time, the reaction is stopped, and the mixed solution after the reaction is filtered. The filter residue is metal tungsten containing a small amount of impurities; the filter residue is dried After dry recovery, it is a tungsten powder product with a tungsten content of more than 95%. The filtrate is a solution containing copper ions, nickel ions, manganese ions and iron ions.

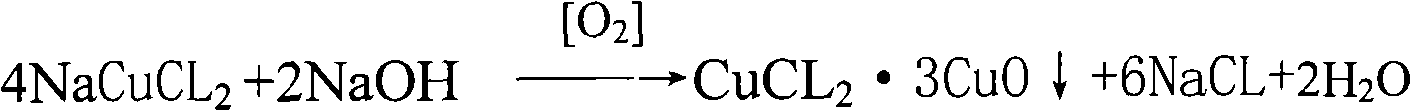

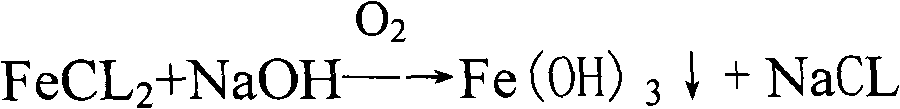

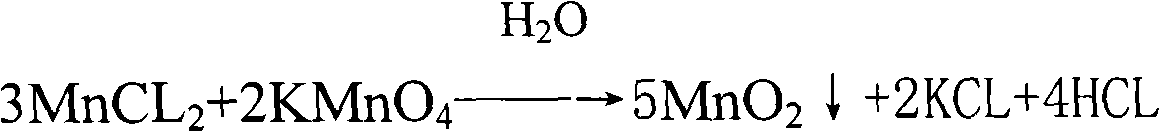

[0028] 2. Copper separation, the filtrate in the previous step is adjusted to a pH value of 3.5 with sodium hydroxide, and air is introduced at 45°C until the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com