Method for improving emission characteristic of film ZnO field

A field emission, thin film technology, applied in the field of field emission flat panel display, can solve the problems of high threshold voltage and low emission current density, and achieve the effect of reducing work function, reducing height and increasing field emission current density

Inactive Publication Date: 2010-11-10

IRICO

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

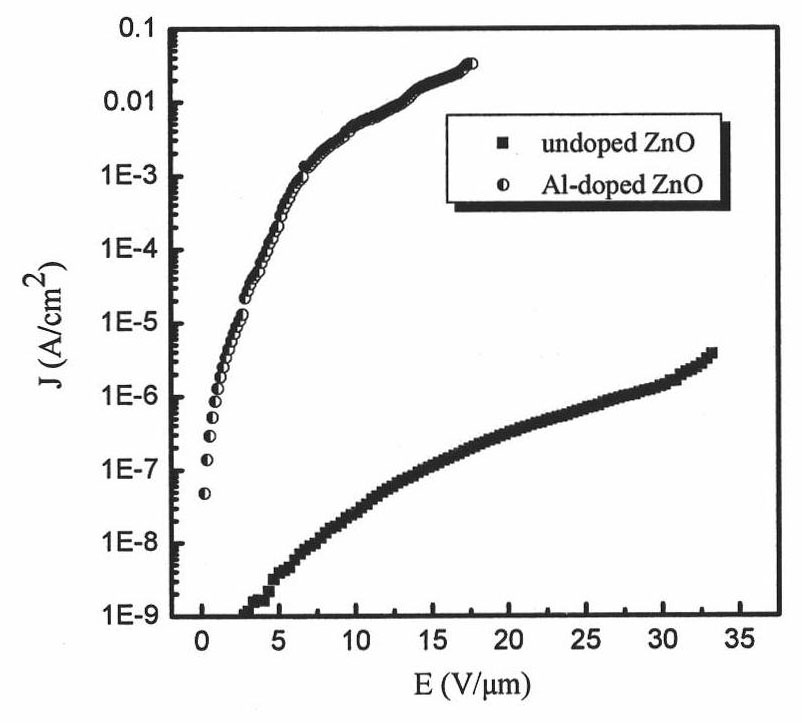

However, the research on ZnO field emission cathode materials is currently mainly focused on one-dimensional nanomaterials prepared by chemical methods. There are few reports on the field emission properties of ZnO thin films prepared by physical methods such as magnetron sputtering. The reason is that although thin film ZnO is used as an electron emitter body, good emission uniformity, high stability, strong adhesion to the substrate, and easy realization of a large area. However, due to the small field emission current density and large threshold voltage of thin-film ZnO emission materials, there is still a certain distance from the actual application level. gap

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

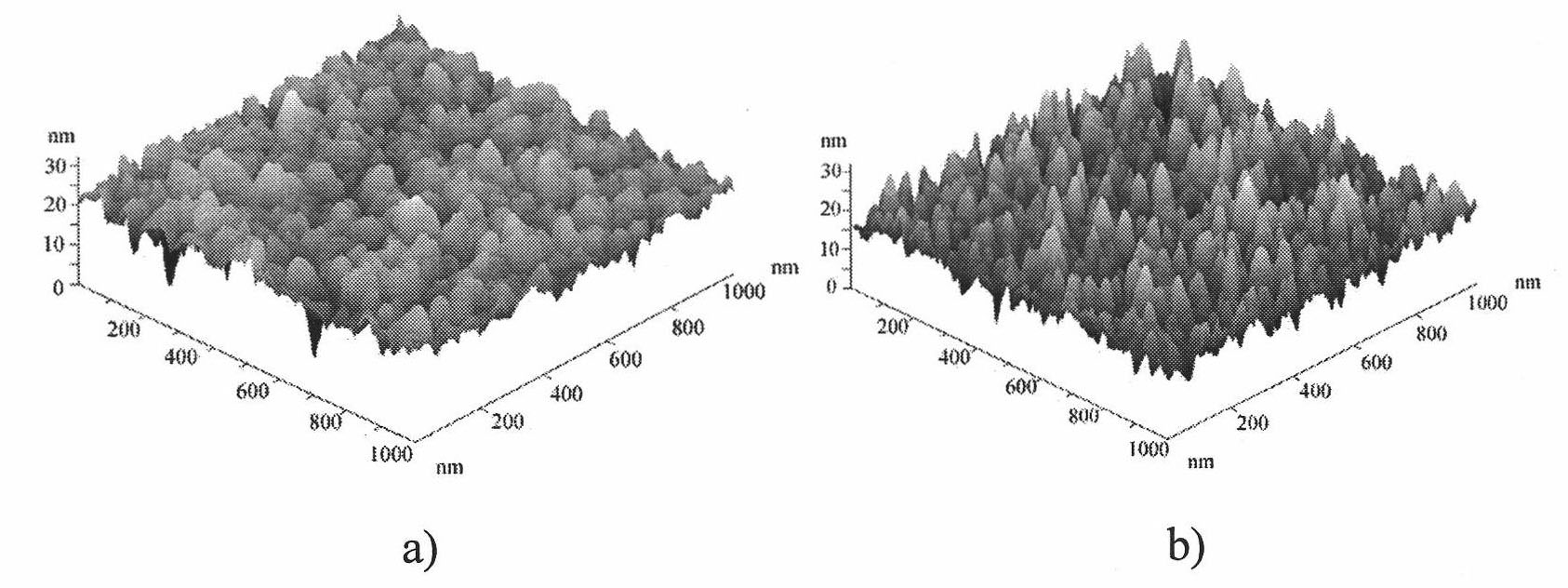

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

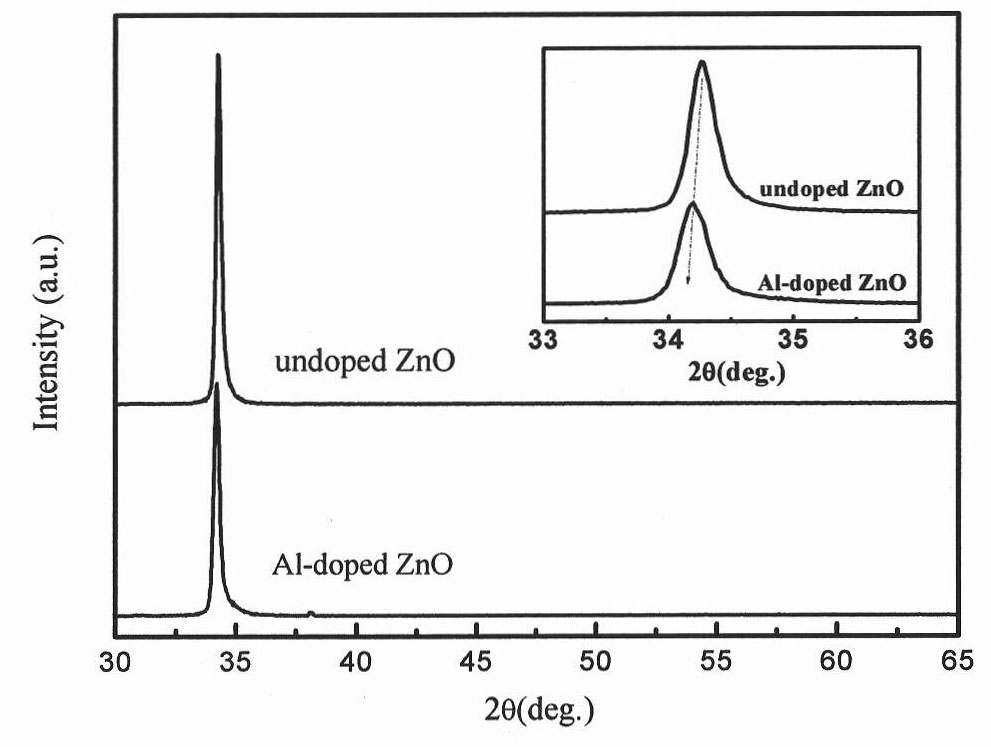

The invention discloses a method for improving the field emission characteristic of film ZnO, which comprises the following steps: firstly, preparing Al doped ZnO ceramic target material; secondly, preparing Al doped ZnO film, cutting the prepared Al doped ZnO film into 0.5cm<2)> to be used as a cathode, using ITO glass as anode, separating the cathode from the anode by using glass thread with 100 micrometers of spacing, and sending KEITHLEY 2410 into a vacuum testing system for the test, wherein the vacuum degree is 5*10 <-7> Pa, the lowest voltage applied between the Al doped ZnO film of the cathode and the ITO glass of the anode is defined as the starting voltage, and the corresponding electric field is the starting field. The method improves the field emission current density of the film ZnO and reduces the field emission starting field strength.

Description

A method for improving field emission characteristics of thin-film ZnO technical field The invention belongs to the technical field of field emission flat panel display, and relates to a preparation technology of a thin-film type field emission material and a method for improving the field emission characteristics of thin-film type ZnO. Background technique "Field emission" has a very wide and important application in vacuum microelectronic devices, such as field emission flat panel displays, high-power electron emission sources, etc., and one of the most critical technologies for these devices is to make cathode electron emitters with excellent performance. Wide bandgap semiconductor ZnO has many excellent properties, especially: good chemical stability, small or even negative electron affinity, high thermal conductivity, oxidation resistance, high temperature resistance, large breakdown field strength And high carrier mobility, large emission current, making it very pop...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01J9/02C23C14/35C23C14/08H01J9/42G01R19/08

Inventor 李军

Owner IRICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com