Flexible optical waveguide, method for producing the same, and epoxy resin composition for flexible optical waveguide

A technology of epoxy resin and optical waveguide, which is applied in the directions of optical waveguide, light guide, optics, etc., can solve the problems of complicated preparation process and increased preparation cost, and achieve the effects of good heat resistance, good flexibility and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

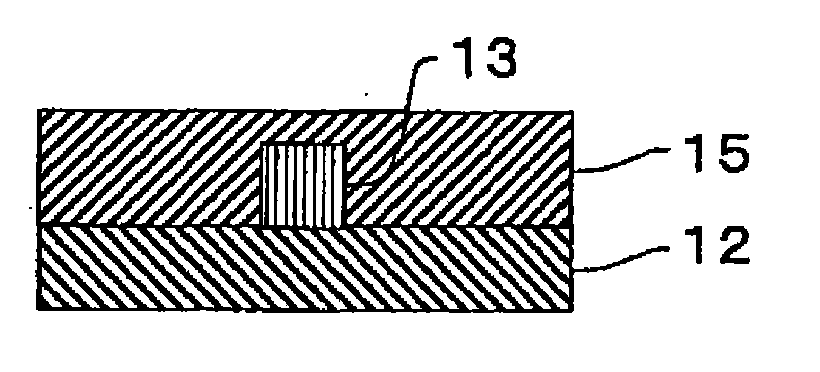

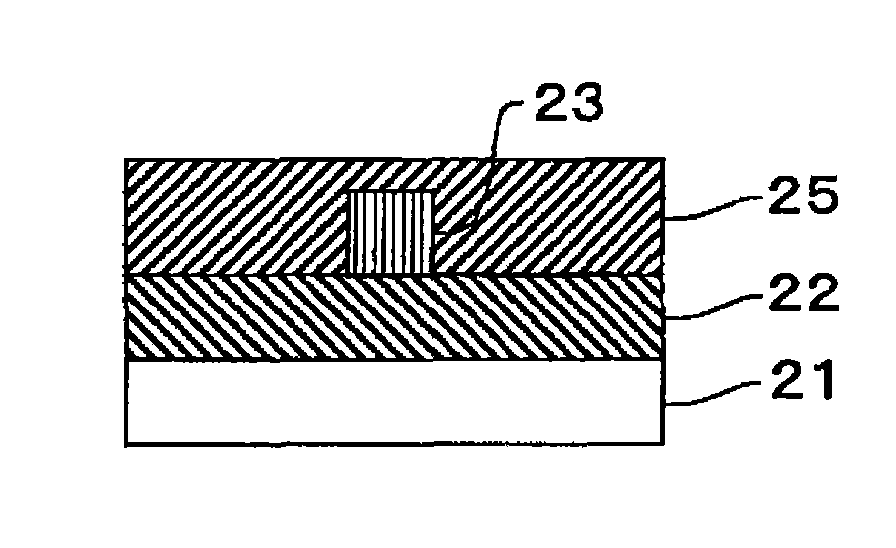

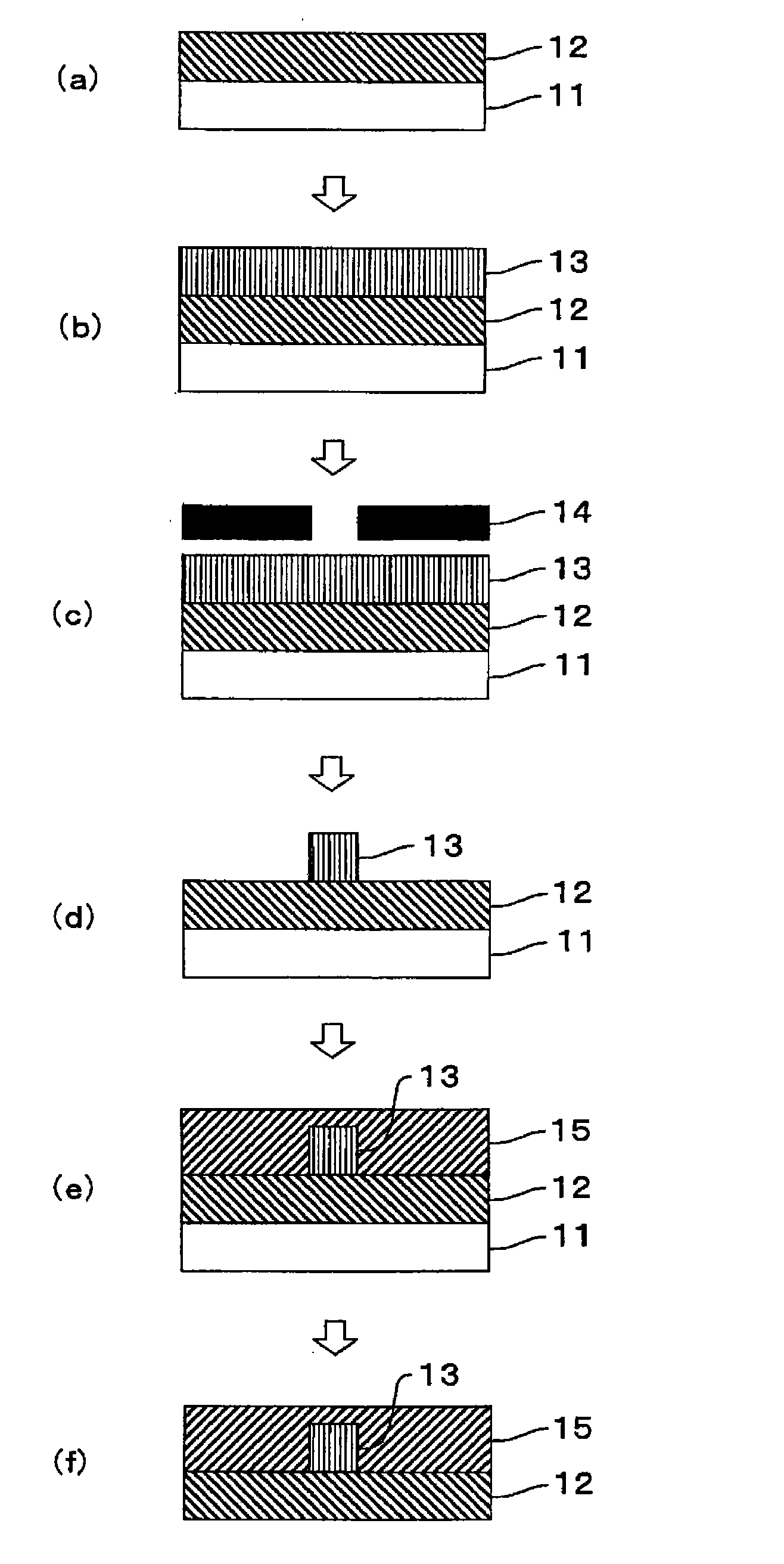

[0144] "Preparation method of flexible optical waveguide"

[0145] The production method of the present invention is characterized in that the production method includes the steps of forming a lower cover layer, forming a center layer on the lower cover layer, and forming a layer between the lower cover layer and the center layer so as to embed the center layer. In the process of forming the upper cladding layer, the epoxy film constituting at least one of the lower cladding layer, the central layer and the upper cladding layer is formed using an epoxy resin composition containing Polyglycidyl compounds of polyalkylene glycol chains and at least two glycidyl groups.

[0146] In this production method, the lower cover layer is formed from the resin composition for the lower cover layer, the center layer is formed from the resin composition for the center layer, and the upper cover layer is formed from the resin composition for the upper cover layer. form. At least one of the ...

Embodiment 1

[0208] First, on a silicon substrate, an epoxy resin composition (1) for a cover layer was spin-coated, and an exposure machine (product name: MA-60F, manufactured by Mikasa Co., Ltd.) using a high-pressure mercury lamp as a light source (wavelength: 365 nm) was used. ), at an illuminance of 10mW / cm 2 Under UV irradiation for 15 minutes, the exposure energy is 9J / cm 2 , forming a lower covering layer formed of an epoxy film with a thickness of 50 μm. The refractive index of the lower cladding layer was measured to be 1.53 at a wavelength of 830 nm using a prism coupler (for example, product name SPA-4000, manufactured by SAIRON TECHNOLOGY, INC.).

[0209] Spin-coat the epoxy resin composition (1) for the center layer on the lower cover layer obtained, and use a high-pressure mercury lamp as a light source (wavelength of 365 nm) exposure machine (product name is MA-60F, ミカサ Co., Ltd.), the illuminance is 10mW / cm 2 Under UV irradiation for 15 minutes, the exposure energy is 9J...

Embodiment 2

[0214] Except that the epoxy resin composition (2) for the covering layer was used instead of the epoxy resin composition (1) for the covering layer when forming the upper covering layer, in the same manner as in Example 1, a film having The flexible optical waveguide (2) of the formed lower cladding layer, central layer and upper cladding layer.

[0215] When the waveguide loss of the obtained flexible optical waveguide (2) was measured without bending, it was 0.13 dB / cm. In addition, based on the test method for polymer waveguides (7.1.1 Bending test JPCA-PE02-05-01S) published by the Japan Print Circuit Industry Association, using the obtained flexible optical waveguide (2), when bending 90 degrees with a radius of 10 mm The waveguide loss was the same value as the waveguide loss measured without bending, and no increase in waveguide loss was confirmed. In addition, when the waveguide loss is measured after being bent at 90 degrees with a radius of 10 mm and returned to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com