Application of alkyl sulfonate to in-furnace desulfurization and desulfurizing and coal saving method

An alkyl sulfonate and furnace desulfurization technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of inability to meet environmental protection technical requirements, inability to directly remove solid sulfur, high investment and operating costs, etc. problems, to achieve the effect of simple structure, good adaptability, raw material cost and operating cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

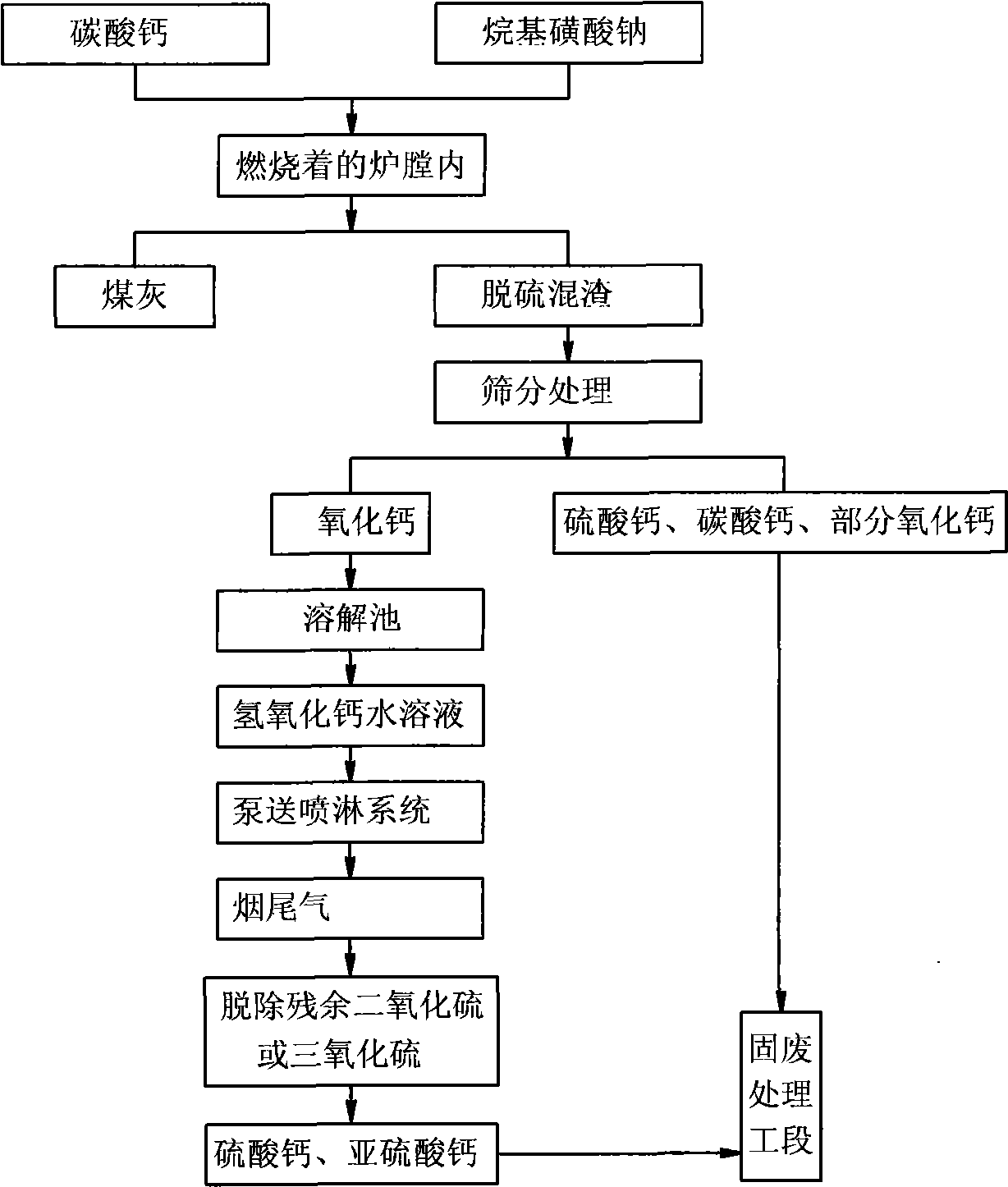

[0030] a. Furnace desulfurization:

[0031] 1. Prepare sodium dodecylsulfonate and CaCO 3 mixture

[0032] The mixture contains 1% sodium dodecyl sulfate;

[0033] 2. With a mass ratio of 1:1000 (mixture / coal), sodium alkylsulfonate and CaCO 3 The mixture is put into the burning furnace, and the chemical reaction is carried out under the high temperature environment in the furnace. The solid sulfur and CaCO in the coal combustion 3 Generate sulfur-containing solid sulfate (main component calcium sulfate) under the action of sodium alkylsulfonate;

[0034] Calcium sulfate, remaining CaCO 3 And the CaO generated by the reaction is discharged in the form of desulfurization mixed slag.

[0035] b. Flue gas desulfurization:

[0036] 1. Sieve out most of the CaO in the above-mentioned desulfurization mixed slag by using a projection vibrating sieving machine. The mesh numbers of the three sets of sieves are 20 mesh, 40 mesh and 60 mesh respectively;

[0037] After screening, ...

Embodiment 2

[0043] a. Furnace desulfurization:

[0044] 1. Prepare sodium pentadecylsulfonate and CaCO 3 The mixture, the mixture contains 1% sodium pentadecyl sulfonate;

[0045] 2. With the mass ratio (mixture / coal) of (0.5—1.5):(500—1500), sodium pentadecylsulfonate and CaCO 3 The mixture is put into the burning furnace, and the chemical reaction is carried out under the high temperature environment in the furnace. The solid sulfur and CaCO in the coal combustion 3 Generate sulfur-containing solid sulfate (main component calcium sulfate) under the action of sodium pentadecylsulfonate;

[0046] Calcium sulfate, remaining CaCO 3 And the CaO generated by the reaction is discharged in the form of desulfurization mixed slag.

[0047] b. Flue gas desulfurization:

[0048] 1. Sieve out most of the CaO in the above-mentioned desulfurization mixed slag by using a projection vibrating sieving machine. The mesh numbers of the three sets of sieves are 20 mesh, 40 mesh and 60 mesh respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com