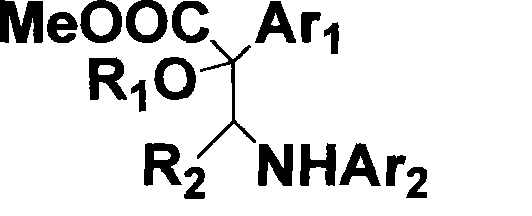

Method for synthesizing alpha-alkoxyl-beta-amino ester derivative

A synthesis method and technology of amino esters, applied in chemical instruments and methods, preparation of organic compounds, preparation of cyanide reaction, etc., can solve problems such as insufficient activation ability of chiral protonic acid, achieve short reaction time and wide source of raw materials , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

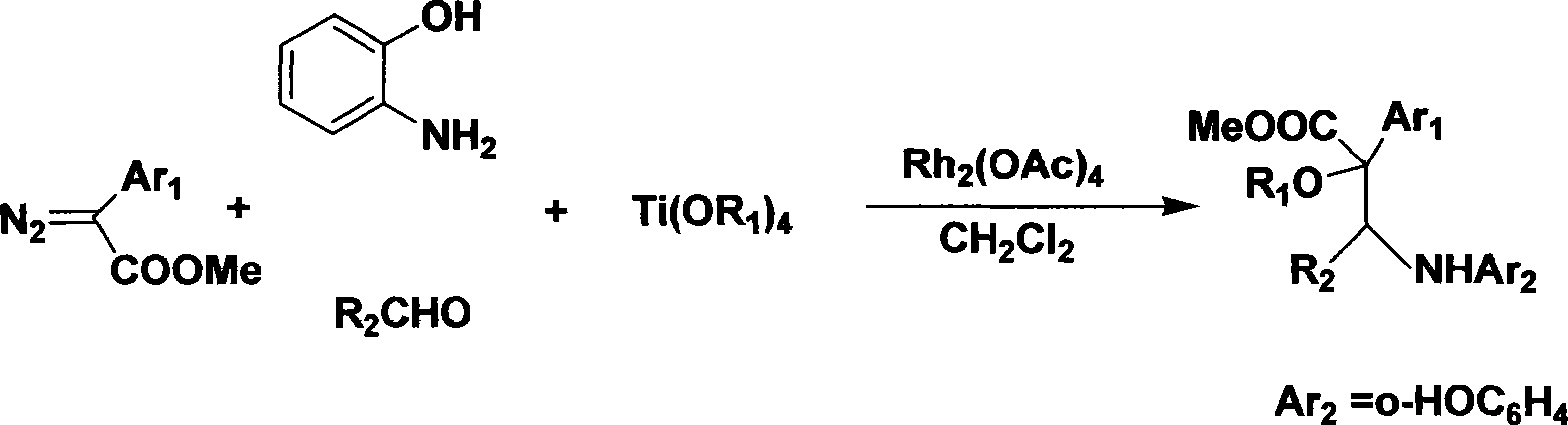

Method used

Image

Examples

Embodiment 1

[0028] Rhodium acetate (0.005mmol), o-aminophenol (0.5mmol), benzaldehyde (0.5mmol), titanium tetraisopropoxide (0.55mmol) and 4 Molecular sieves (250mg) were dissolved in 6ml CH 2 Cl 2 , stirred at room temperature for 2 to 3 hours to prepare a reaction system, dissolved methyl phenyldiazoacetate (1.0mmol) in 3ml CH 2 Cl 2 Inject the solution in the above reaction system slowly with the injection pump, and the time is controlled for 1 to 3 hours. After the injection is completed, the reaction is continued for 2 to 3 hours, and then saturated NaHCO is added dropwise to the reaction system. 3 The aqueous solution was used to quench the reaction, and the solvent was removed by rotary evaporation under reduced pressure to obtain a crude product, which was subjected to column chromatography (ethyl acetate:petroleum ether=1:50~1:20) to obtain a pure product. Yield 75%, dr value 79:21. Yellow oil; 1 H NMR (500MHz, CDCl 3 )δ (ppm) 7.25-7.35 (m, 5H), 7.10-7.13 (m, 3H), 6.97-6.9...

Embodiment 2

[0030] Rhodium acetate (0.005mmol), o-aminophenol (0.5mmol), p-chlorobenzaldehyde (0.5mmol), titanium tetraisopropoxide (0.55mmol) and 4 Molecular sieves (250mg) were dissolved in 6ml CH 2 Cl 2 , stirred at room temperature for 2 to 3 hours to prepare a reaction system, methyl phenyldiazoacetate (1.0mmol) was dissolved in 3ml CH 2 Cl 2 In the process, use the injection pump to slowly inject the solution into the above reaction system, and the time is controlled for 1 to 3 hours. After the injection is completed, continue to react for 2 to 3 hours, and then add saturated NaHCO to the reaction system dropwise. 3 The aqueous solution was used to quench the reaction, the solvent was removed by rotary evaporation under reduced pressure, and the crude product was subjected to column chromatography (ethyl acetate:petroleum ether=1:50~1:20) to obtain a pure product. The yield was 68%, and the dr value was 74:26. Yellow oil; 1 H NMR (300MHz, CDCl 3 )δ (ppm) 7.25-7.34 (m, 4H), 7....

Embodiment 3

[0032] Rhodium acetate (0.005mmol), o-aminophenol (0.5mmol), p-methoxybenzaldehyde (0.5mmol) and tetraethoxytitanium (0.55mmol)4 Molecular sieves (250mg) were dissolved in 6ml CH 2 Cl 2 , stirred at room temperature for 2 to 3 hours to prepare a reaction system, methyl phenyldiazoacetate (1.0mmol) was dissolved in 3ml CH 2 Cl 2 Inject the solution in the above reaction system slowly with the injection pump, and the time is controlled for 1 to 3 hours. After the injection is completed, the reaction is continued for 2 to 3 hours, and then saturated NaHCO is added dropwise to the reaction system. 3 The aqueous solution was used to quench the reaction, the solvent was removed by rotary evaporation under reduced pressure, and the crude product was subjected to column chromatography (ethyl acetate:petroleum ether=1:50~1:20) to obtain a pure product. The yield was 53%, and the dr value was 67:33. Yellow oil; 1 H NMR (300MHz, CDCl 3 )δ (ppm) 7.26-7.38 (m, 5H), 6.89-6.92 (d, 2H)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com