Method for preparing zinc sulfide quantum wire by using template method

A technology of quantum wire and zinc sulfide, which is applied in the field of nanomaterial preparation, can solve the problems of application limitations, lack of physical properties, large diameter, etc., and achieve low production cost, simple and easy preparation method, and high emission current density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

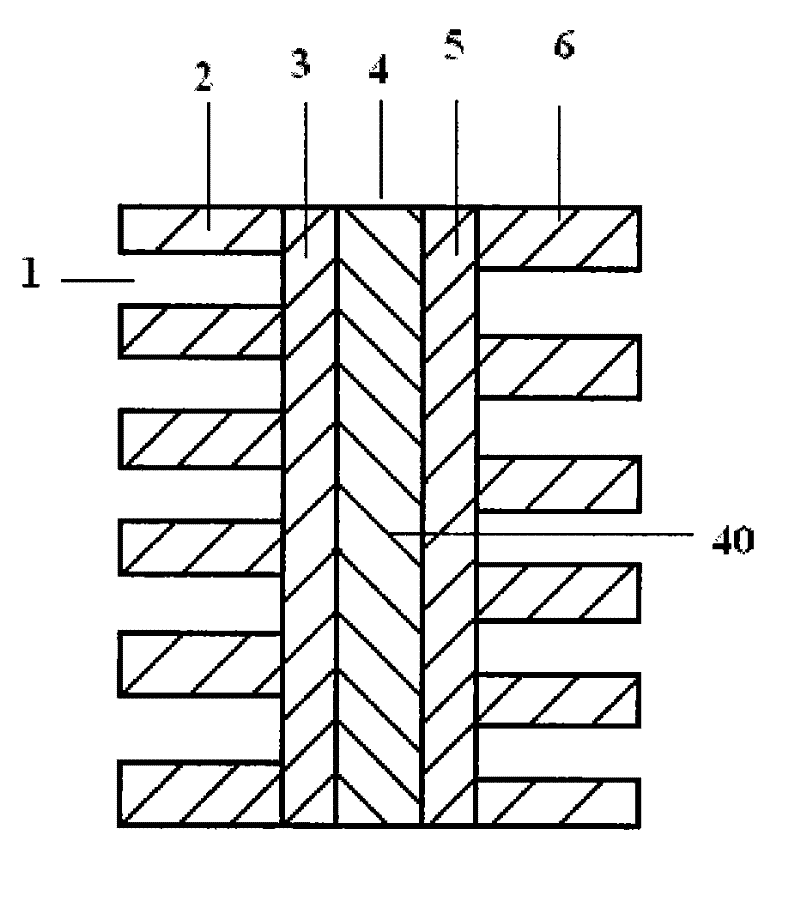

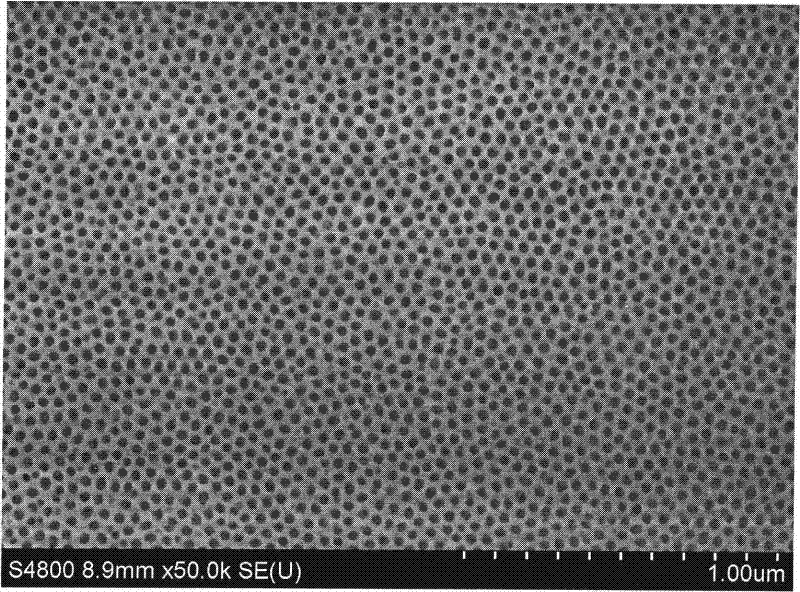

[0037] In the first step, the substrate 4 is annealed at 450°C for 4 hours and electrochemically polished at 0°C for 30 seconds; in the second step, the concentration of the sulfuric acid solution is 12wt%, the temperature of the primary anodization is -6°C, and the anodizing The time and current are 2 hours and 10mA respectively; in the third step, the water bath time is 40 minutes, the concentration of the sulfuric acid solution is 12wt%, the temperature of the secondary anodization is -6°C, and the anodization time and current are 2 hours and 10mA; in the fourth step, water bath for 40 minutes; in the fifth step, the solution of dealuminization 40 is SnCl with a concentration of 10wt% 4 Solution, the soaking time is 8 hours; in the sixth step, the reaction time is 10 minutes; in the ninth step, the deposition time is 10 minutes.

Embodiment 2

[0039] In the first step, the substrate 4 is annealed at 550°C for 4.5 hours and electrochemically polished at 5°C for 40 seconds; in the second step, the concentration of the sulfuric acid solution is 14wt%, the temperature of the primary anodization is 0°C, and the anodizing time And the current is 3.5 hours and 6mA respectively; in the third step, the water bath time is 45 minutes, the concentration of the sulfuric acid solution is 14wt%, the temperature of the secondary anodization is 0°C, the anodization time and current are 3 hours and 7mA respectively; In the fourth step, water bath for 50 minutes; in the fifth step, the solution of dealuminization 40 is SnCl with a concentration of 13wt% 4 Solution, the soaking time is 6 hours; in the sixth step, the reaction time is 13 minutes; in the ninth step, the deposition time is 15 minutes.

Embodiment 3

[0041] In the first step, the substrate 4 is annealed at 650°C for 5 hours and electrochemically polished at 10°C for 50 seconds; in the second step, the concentration of the sulfuric acid solution is 16wt%, the temperature of the primary anodization is 6°C, and the anodizing time And the current is 5 hours and 2mA respectively; in the third step, the water bath time is 50 minutes, the concentration of the sulfuric acid solution is 16wt%, the temperature of the secondary anodization is 6°C, the anodization time and current are 5 hours and 2mA respectively; In the fourth step, water bath for 60 minutes; in the fifth step, the solution of dealuminization 40 is SnCl with a concentration of 16wt% 4 Solution, soaking time is 4 hours; in the sixth step, the reaction time is 16 minutes; in the ninth step, the deposition time is 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com