Micro-spectrum analysis method and device based on Fresnel zone plate

A Fresnel zone plate and spectrum analysis technology, applied in the field of spectrum analysis, can solve the problems of no Fresnel zone plate, complex processing technology, small diffraction area, etc., to avoid light energy loss, device Compact structure, improve the effect of detecting light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

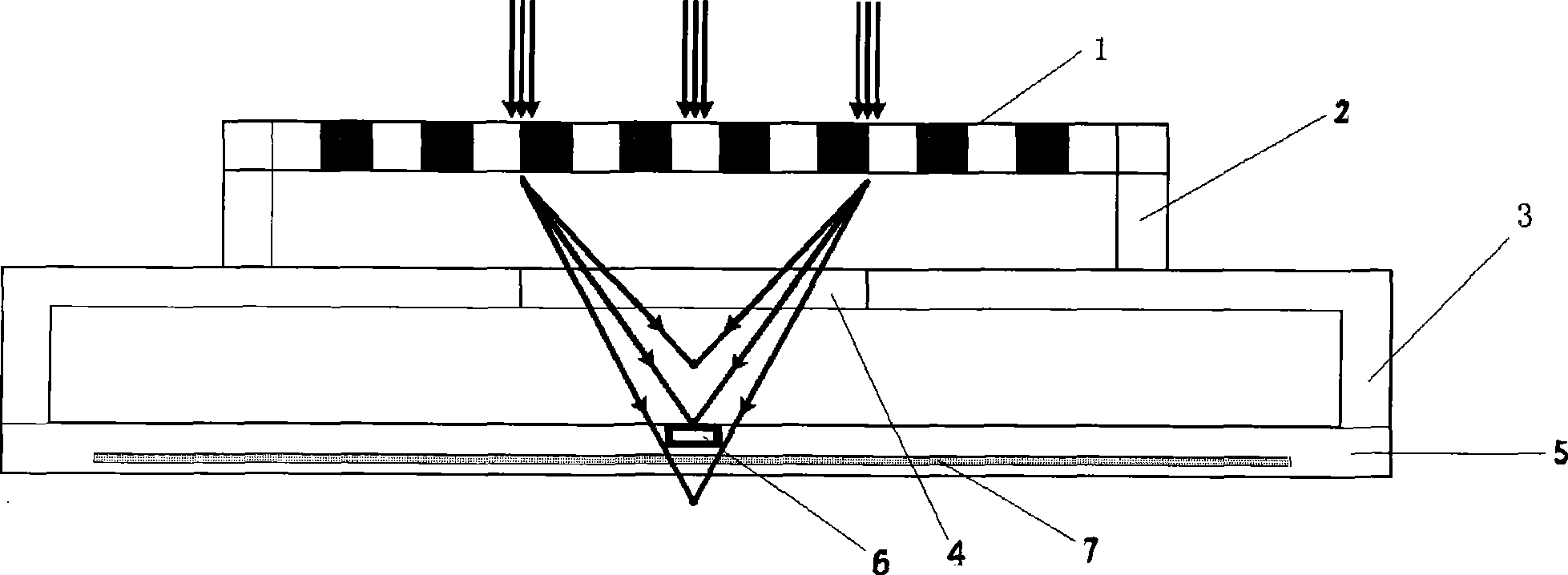

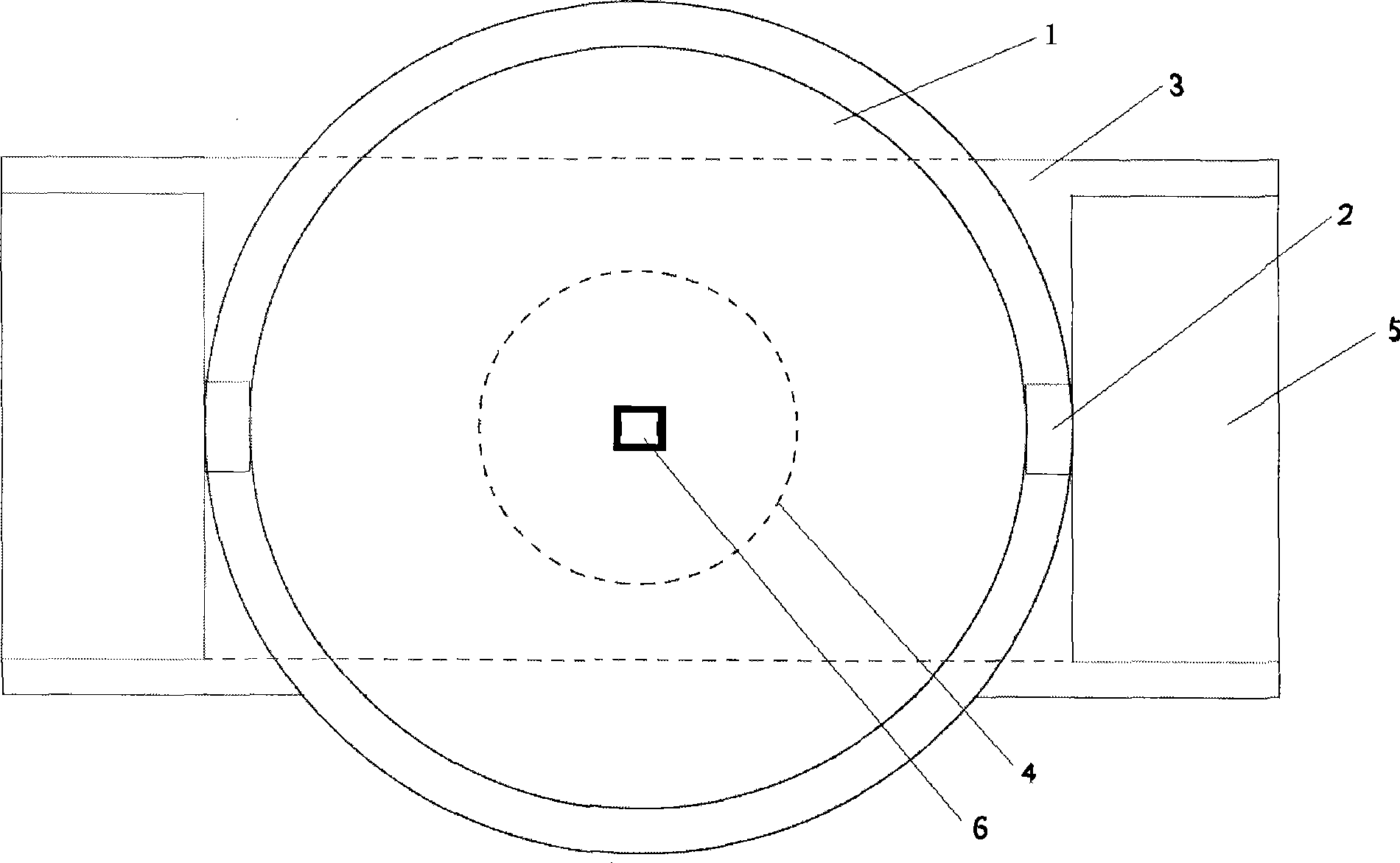

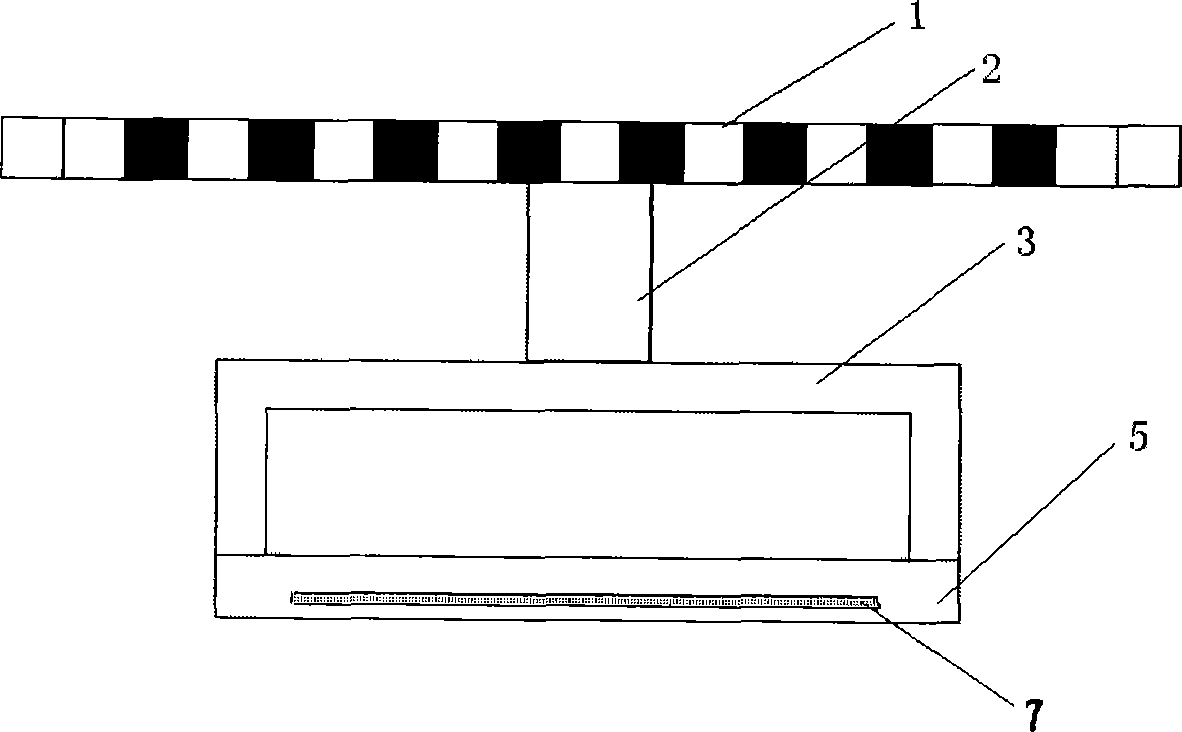

[0015] The processing technology of the micro-spectral analysis device based on the Fresnel zone plate is realized as follows: first, the driving circuit unit and the bottom electrode 7 are processed on the silicon substrate by using CMOS technology, and an insulating layer is deposited, and a single semiconductor photodetector is integrated at the same time. Unit 6. The bridge support structure 3 is manufactured by silicon micromachining technology, and is electrically connected with the driving circuit unit of the lower layer and the bottom electrode 7, and the Fresnel zone plate 1 is manufactured on the bridge support structure 3 by optical micromachining technology and There are support columns 2 to realize bridge support at both ends; and the focus of the Fresnel zone plate 1 is just located on the photodetection unit 6 . In this way, the electrostatic drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com