Membrane electrode and current collecting board element of electrochemical cell and electrochemical cell module

A current collection and battery module technology, applied in the field of electrochemical batteries, can solve the problems of high manufacturing cost, high requirements for bipolar plates, complex structure and assembly process, etc., to simplify the structure and assembly process, reduce costs, and increase the effective area The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

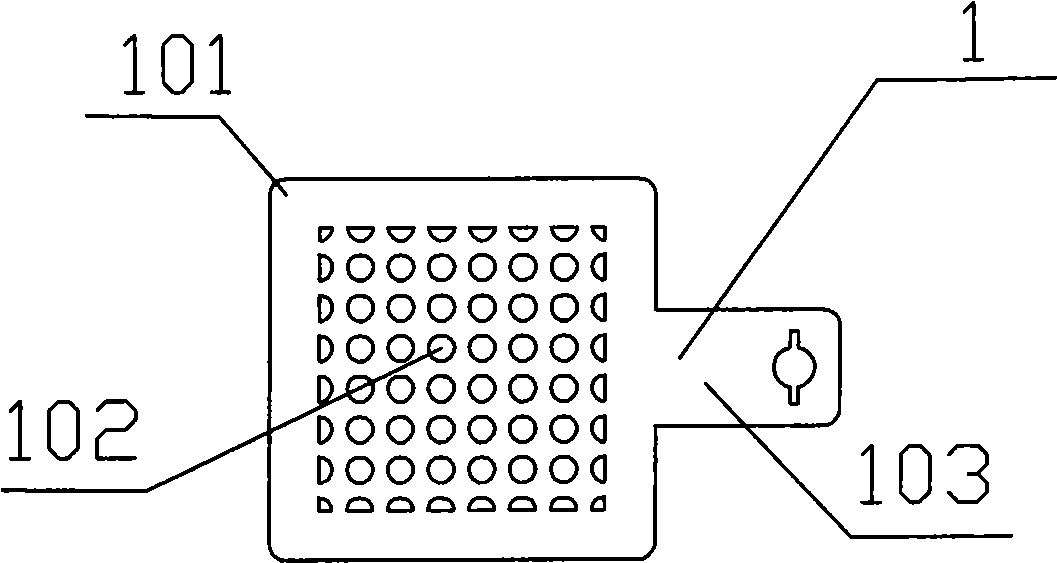

[0031] figure 1 Shown is a metal plate 1 acting as a porous current collector plate on one side, its middle area is covered with tiny through holes, which is the reactive area 101, and its non-porous outer ring is the non-reactive area 102, with a handle-like extension on the right It is the electrical lead-out area 103, and the end of the electrical lead-out area has a through hole for electrical connection.

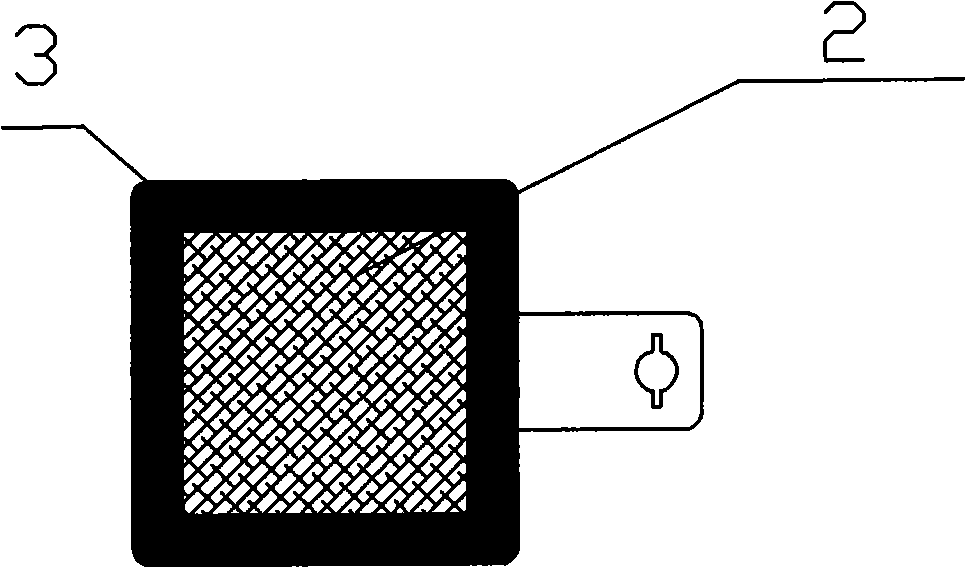

[0032] figure 2 Shown is an intermediate product with carbon paper 2 as a gas diffusion layer on one side and glue 3 as a sealing material; the area of carbon paper 2 basically corresponds to the reaction area 101 of metal plate 1; the position of glue 3 is the same as that of the metal plate The non-reactive region 102 of 1 basically corresponds.

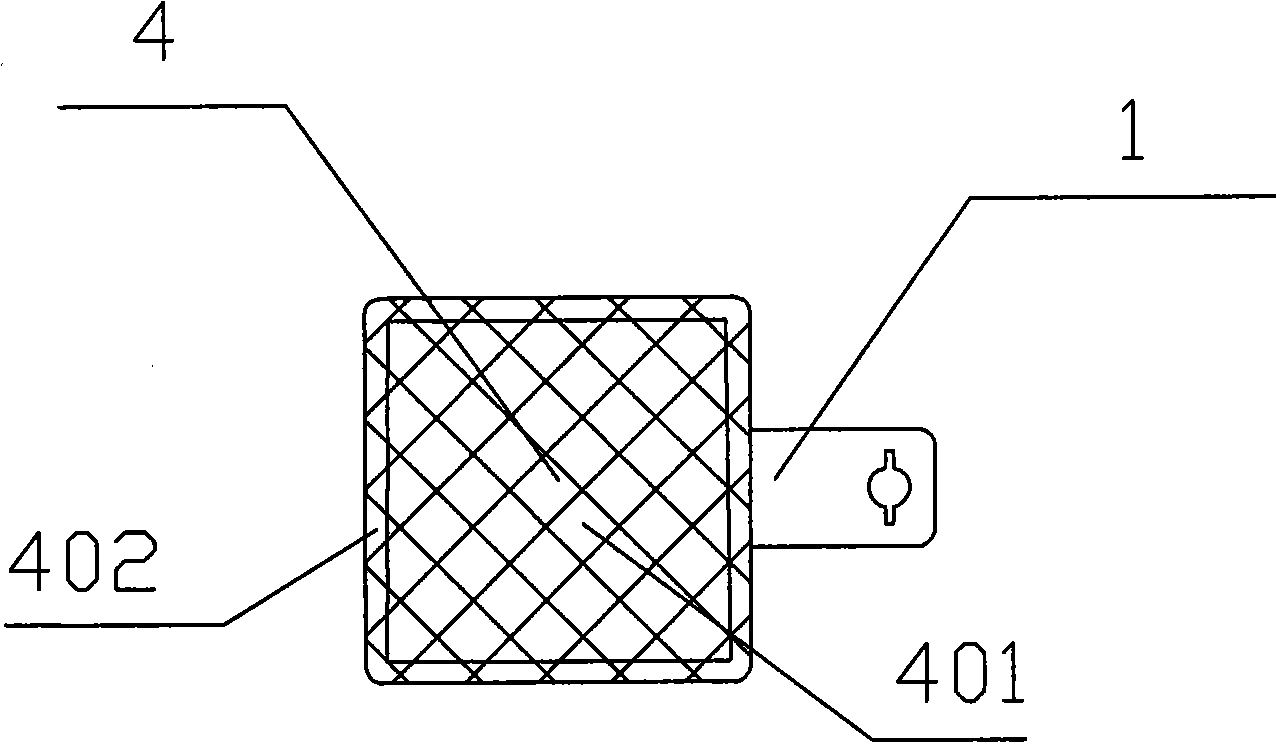

[0033] image 3 Shown is the assembly with a membrane 4 added, the middle part of the membrane 4 being the reaction zone 401 and the outer circle being the non-reaction zone 402 .

[0034] The glue 3 fills the space ...

Embodiment 2

[0038] Figure 5 It is an extension of the component shown in Example 1. The carbon paper 5 serving as the gas diffusion layer on the other side, the metal plate 6 serving as the porous current collecting plate on the other side, and the glue 7 serving as the sealing material are added.

[0039] The positional relationship of carbon paper 5, metal plate 6, and glue 7, the distribution of reaction area, non-reaction area and electric lead-out area are similar to the situation of metal plate 1, film 4 and carbon paper 2 in Example 1, and the attached figure is clear enough , no longer numbered for each region.

Embodiment 3

[0041] Figure 6 It is an extension of the component shown in Example 1. A metal plate 6 acting as a porous current collecting plate on the other side and a glue 7 acting as a sealing material are added. Since this assembly is used to assemble the electrolytic cell module, the electrolytic cell has a high polarization overvoltage during operation, in order to avoid galvanic corrosion, there is no carbon paper 5, so the glue 7 is very thin and can hardly be seen in the figure. Other positional relationships are similar to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com