Silicon rubber/gadoleic acid cholesterol ester liquid crystal cross linking membrane and preparation method and applications thereof

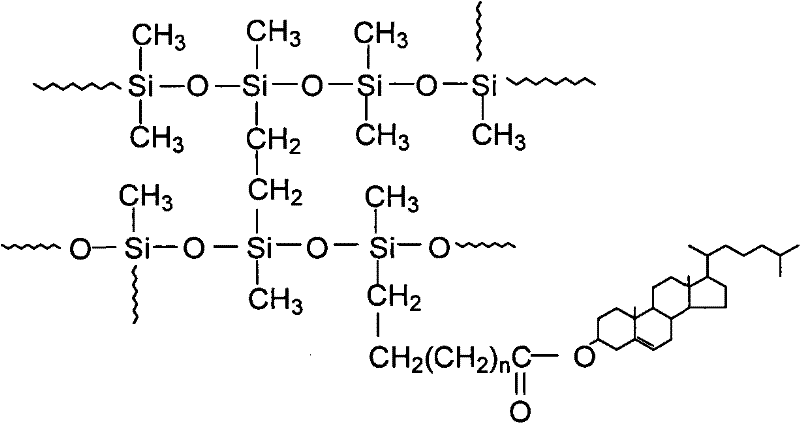

A technology of cholesteryl enoate and silicone rubber, which is applied in the field of functional polymer membrane materials, can solve the problems of small molecular liquid crystal compounds entering the human body, improve blood compatibility and biocompatibility, improve air permeability, and avoid The effect of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

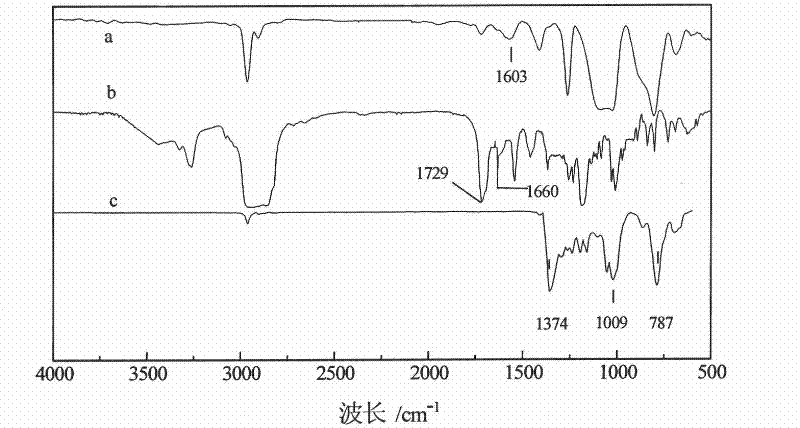

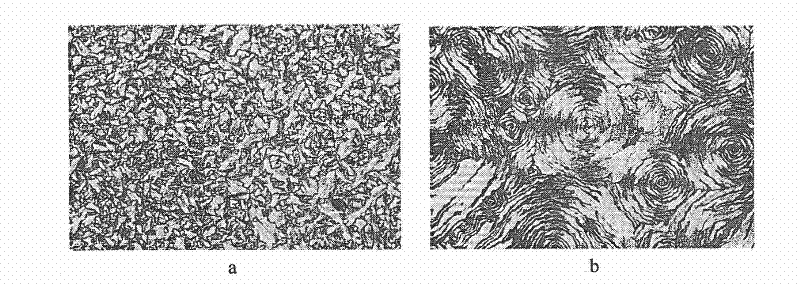

Method used

Image

Examples

Embodiment 1

[0032] (1) Mix 0.025mol vinyl silicone rubber and 0.025mol cholesteryl crotonate liquid crystal, dissolve in tetrahydrofuran, stir evenly, and form a uniform solution with a mass fraction of 5.0%;

[0033] (2) Slowly add 0.012g of hydrogen-containing silicone oil and 0.006g of chloroplatinic acid solution dropwise in the uniform solution, and cross-link at room temperature for 10 minutes to obtain a transparent and viscous liquid crystal / silicone rubber solution for preliminary reaction;

[0034] (3) Use the framework to cast the silicone rubber / liquid crystal solution obtained in step (2) on a polyethylene terephthalate (PET) film to form a film, evaporate the solvent naturally, dry for 12 hours, peel off the film after solidification, and obtain the thickness A transparent and flexible silicone rubber / cholesteryl crotonate liquid crystal cross-linked film with a thickness of about 30 μm was dried in a vacuum desiccator at room temperature for one day and set aside.

[0035] ...

Embodiment 2

[0040] (1) Mix 0.025mol vinyl silicone rubber and 0.025mol cholesteryl pentenoate liquid crystal, dissolve with tetrahydrofuran, stir evenly, and form a uniform solution with a mass fraction of 2.5%;

[0041] (2) Slowly add 0.012g of hydrogen-containing silicone oil and 0.006g of chloroplatinic acid solution dropwise in the uniform solution, and cross-link at room temperature for 25 minutes to obtain a transparent and viscous liquid crystal / silicone rubber solution for initial reaction;

[0042](3) Use the frame to cast the liquid crystal / silicone rubber solution obtained in step (2) on a polyethylene terephthalate (PET) film to form a film, evaporate the solvent naturally, dry for 18 hours, peel off the film after solidification, and obtain the thickness A transparent and flexible silicone rubber / cholesteryl pentenoate liquid crystal cross-linked film with a thickness of about 40 μm was dried in a vacuum desiccator at room temperature for one day and set aside.

[0043] Since...

Embodiment 3

[0048] (1) Mix 0.025mol vinyl silicone rubber and 0.025mol cholesteryl undecylenate liquid crystal, dissolve with tetrahydrofuran, stir evenly, and form a uniform solution with a mass fraction of 12.5%;

[0049] (2) Slowly add 0.012g of hydrogen-containing silicone oil and 0.006g of chloroplatinic acid solution dropwise in the uniform solution, and cross-link at room temperature for 20 minutes to obtain a transparent and viscous silicone rubber / liquid crystal solution for initial reaction;

[0050] (3) Cast the silicone rubber / liquid crystal solution obtained in step (2) on a polyethylene terephthalate (PET) film to form a film using a frame, naturally evaporate the solvent, dry for 24 hours, and carefully peel off the film after solidification to obtain A transparent and flexible silicone rubber / cholesteryl undecylenate liquid crystal cross-linked film with a thickness of about 30 μm. Dry in a vacuum desiccator at room temperature for one day and set aside. The above reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com