Extraction method of fish skin collagen

A technology of fish skin collagen and fish collagen, which is applied in the fields of pharmaceutical formula, food preparation, food science, etc., to achieve the effects of low cost, solving environmental pollution and safety hazards, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

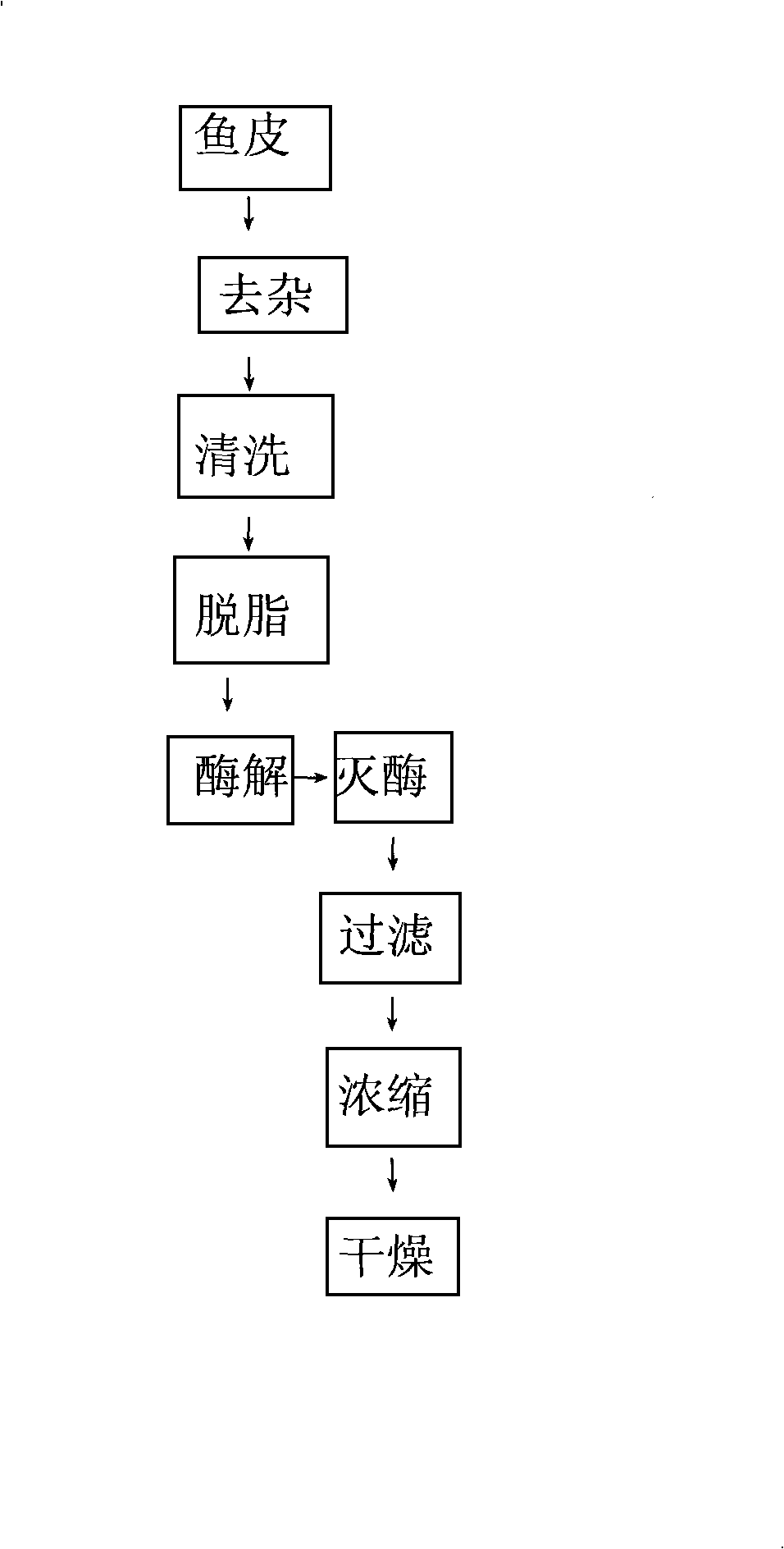

Image

Examples

Embodiment 1

[0024] Accurately weigh and remove impurities, wash 1 kg of fresh fish skin, add 2 kg of distilled water, and stir well. Heat the suspension to 35°C-70°C, adjust the pH to 9 with calcium hydroxide, add 10 grams of triacylglycerol lipase, and the enzymatic hydrolysis time is 2 hours, then add 12 grams of alkaline protease, and the enzymatic hydrolysis time is After 4 hours, the temperature was raised to 95°C and kept for 10 minutes to inactivate the enzyme, and then the enzymolysis solution was filtered to obtain the supernatant and filter residue, and the supernatant was concentrated and dried to obtain fish skin collagen.

Embodiment 2

[0026] Accurately weigh and remove impurities, wash 2 kg of fresh fish skin, add 3 kg of distilled water, and stir evenly. Heat the suspension to 35°C-70°C, adjust the pH to 10 with calcium hydroxide, add 15 grams of diacylglycerol lipase, and the enzymolysis time is 1.5 hours, then add 20 grams of papain, and the enzymolysis time is 5 hours. hours, then raise the temperature to 95°C and keep for 10 minutes to inactivate the enzyme, then filter the enzymolysis solution to obtain supernatant and filter residue, the supernatant is concentrated and dried to obtain fish skin collagen.

Embodiment 3

[0028] Accurately weigh and remove impurities, wash 5 kg of fresh fish skin, add 8 kg of distilled water, and stir evenly until the fish scale powder becomes a suspension. Heat the suspension to 35°C-70°C, adjust the pH to 8 with calcium hydroxide, add 20 grams of monoacylglycerol lipase, and the enzymatic hydrolysis time is 1.8 hours, then add 30 grams of trypsin, and the enzymatic hydrolysis time is 4 hours hours, then raise the temperature to 95°C and keep for 10 minutes to inactivate the enzyme, then filter the enzymolysis solution to obtain supernatant and filter residue, the supernatant is concentrated and dried to obtain fish skin collagen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com