Hydraulic slip-and-lift construction method for water tower

A construction method and hydraulic technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., to achieve the effects of small construction safety hazards, overcoming large material consumption, and reducing high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

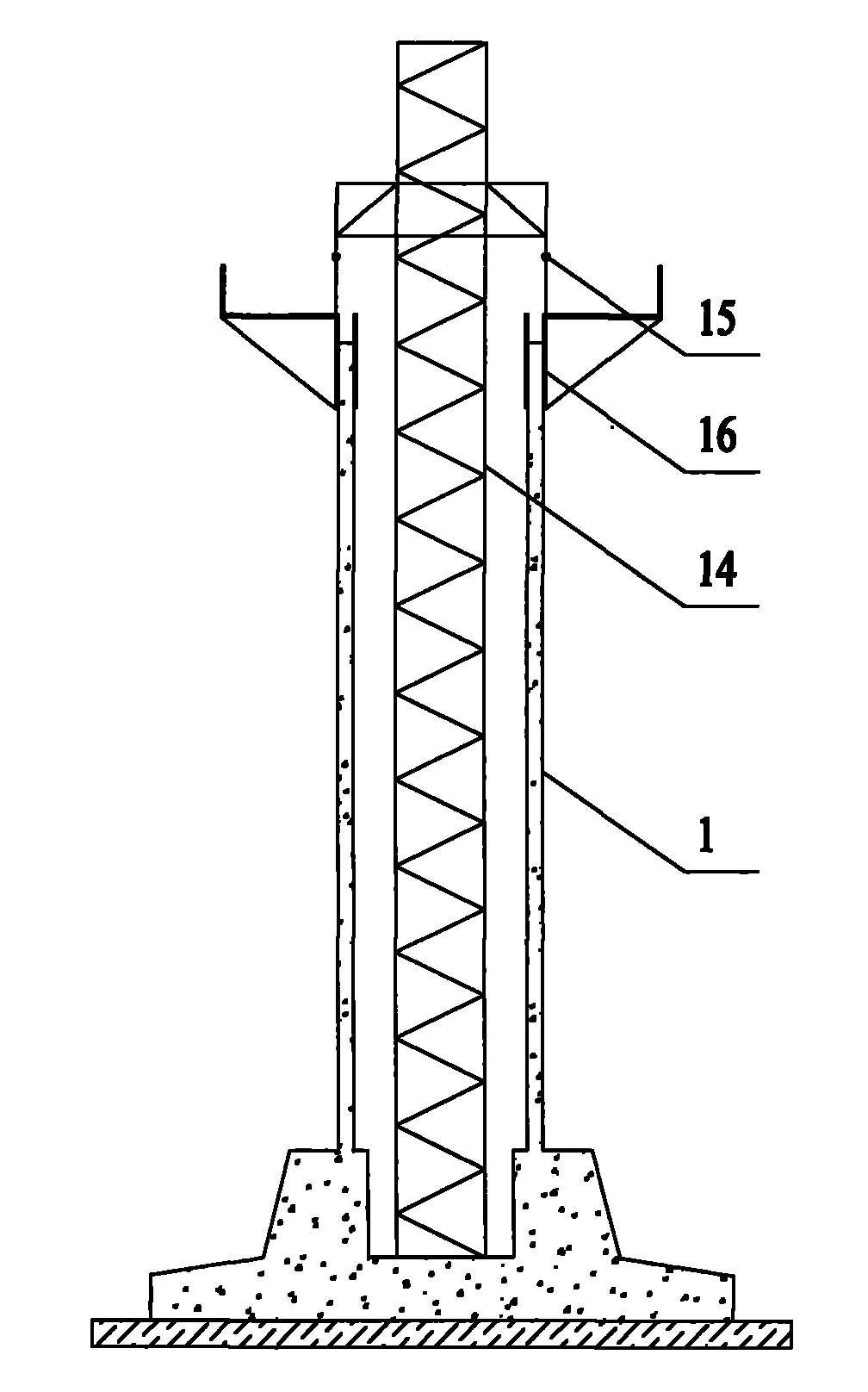

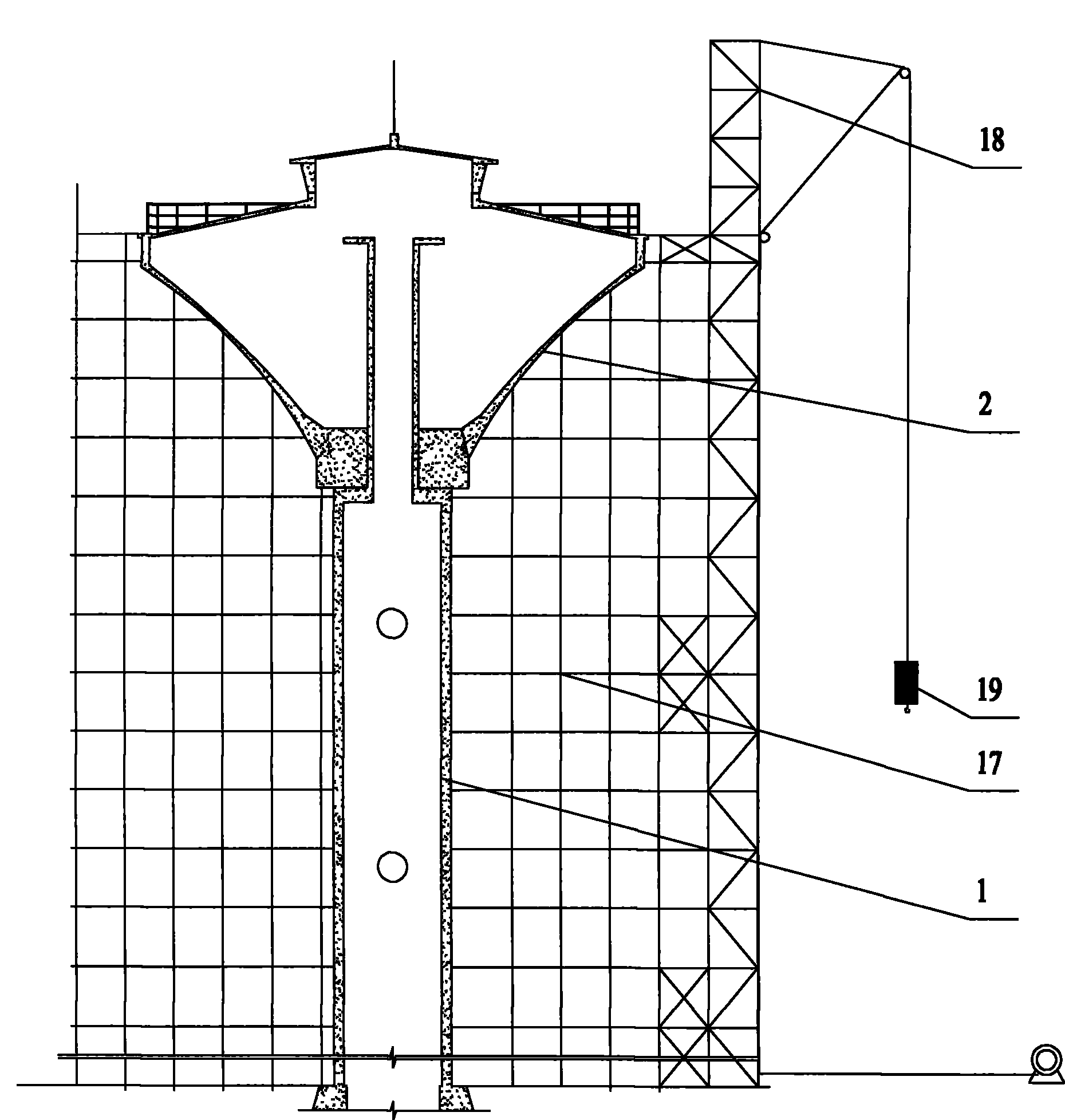

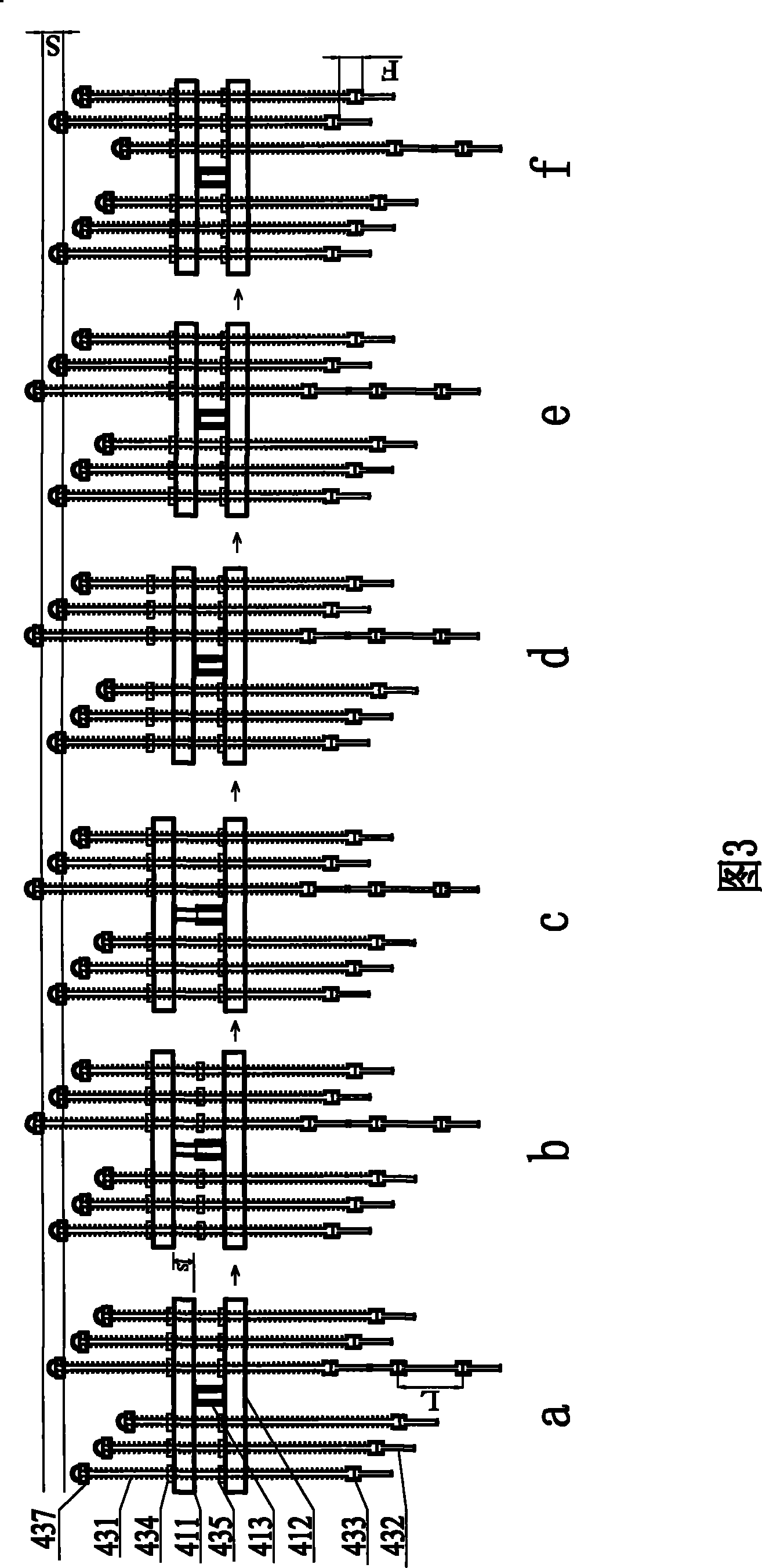

[0090] The water tower of a steel factory is designed to be 1000m 3 / 40m reinforced concrete hyperbolic thermal insulation water tower, the effective volume of the water tower water tank is 1000m 3 , the minimum water level of the water stored in the tower is 40m, and the water tank of the water tower has an arc shape. In this embodiment, the water tower is constructed using a dual-hydraulic combined sliding-lifting construction process (that is, the hydraulic sliding form construction process of the support tube and the hydraulic lifting construction process of the water tank prefabrication).

[0091] The water tower construction project of this embodiment is mainly composed of four parts: foundation engineering, support tube construction, water tank construction and project finishing. The foundation of the water tower is a reinforced concrete circular cup foundation, which falls on the 6-1 residual sandy clay layer, and the bearing capacity of the foundation soil is f k=18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com