Device and process for processing nitrogen-oxide waste gas containing acidic gas

A waste gas treatment device and nitrogen oxide technology, which is applied in the field of protecting the environment and preventing nitrogen oxides from causing atmospheric pollution, can solve the problems of unsatisfactory technical and economic indicators and effects, easy leakage of reducing agents, and high operating costs, and achieves a degree of automation High, easy to operate, simple effect of waste gas treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

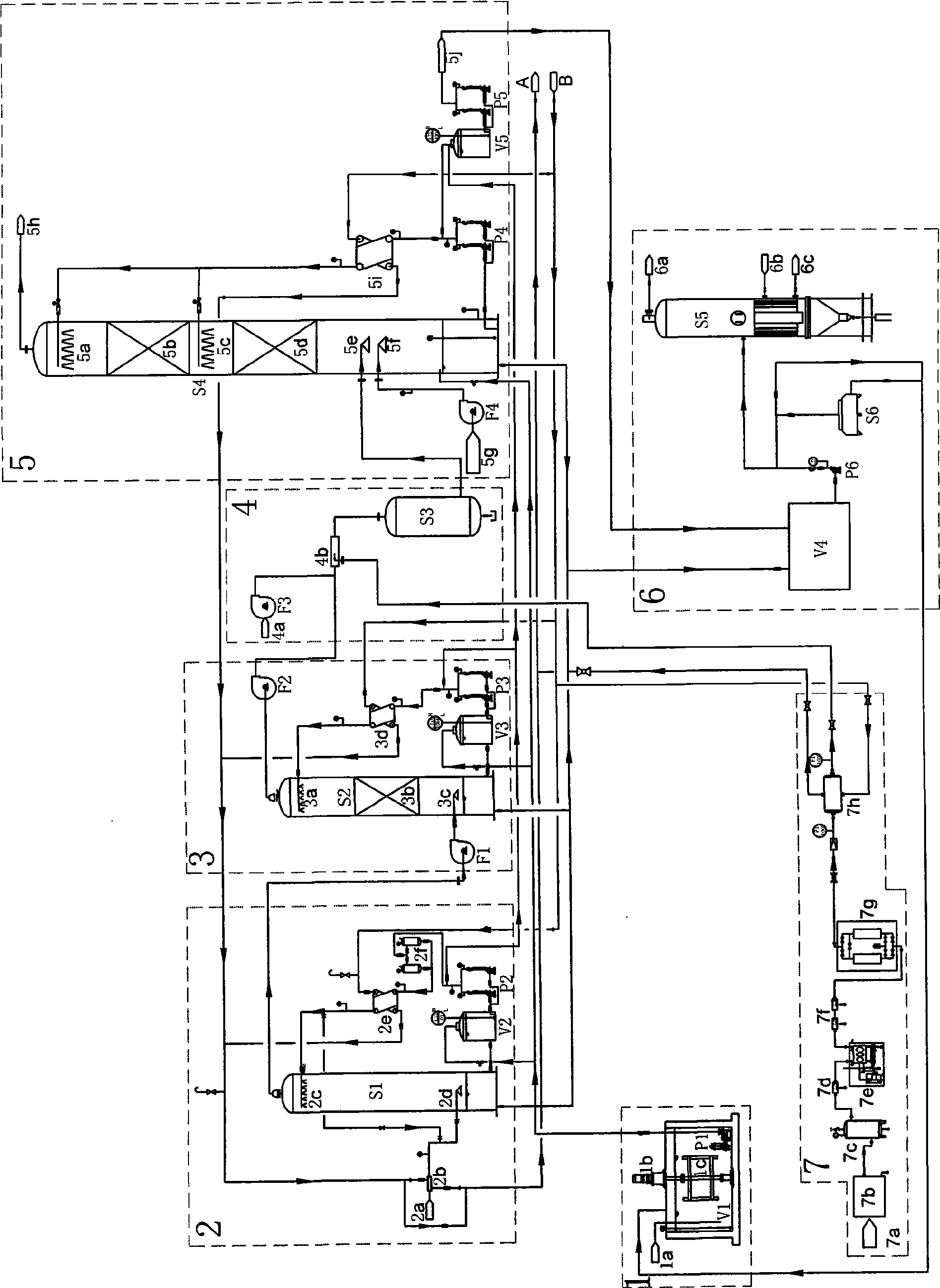

[0034] figure 1 A system diagram of a nitrogen oxide waste gas treatment device containing acid gas is shown. In the figure, 7 systems are framed by dotted lines, which are lye configuration and distribution system 1 ( figure 2 ), dust removal lye circulation absorption system 2 ( image 3 ), a lye circulation absorption system 3 ( Figure 4 ), ozone oxidation reaction system 4, secondary lye circulation absorption system 5 ( Image 6 ), waste liquid recycling system 6 ( Figure 5 ) and ozone generating system 7.

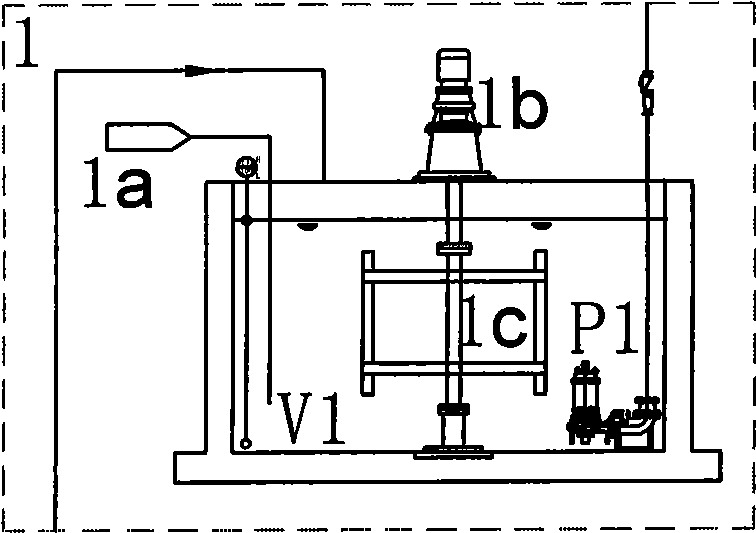

[0035] figure 2 The shown lye configuration and distribution system 1 is mainly provided with an alkali distribution pool V1, in which an agitator 1c driven by an agitator 1b and an lye lifting pump P1 are provided. Add water into the alkali distribution pool V1 through the tap water inlet 1a, and then put in flake sodium hydroxide. The ratio of sodium hydroxide to water is 1:10, and start the mixer 1b to stir evenly.

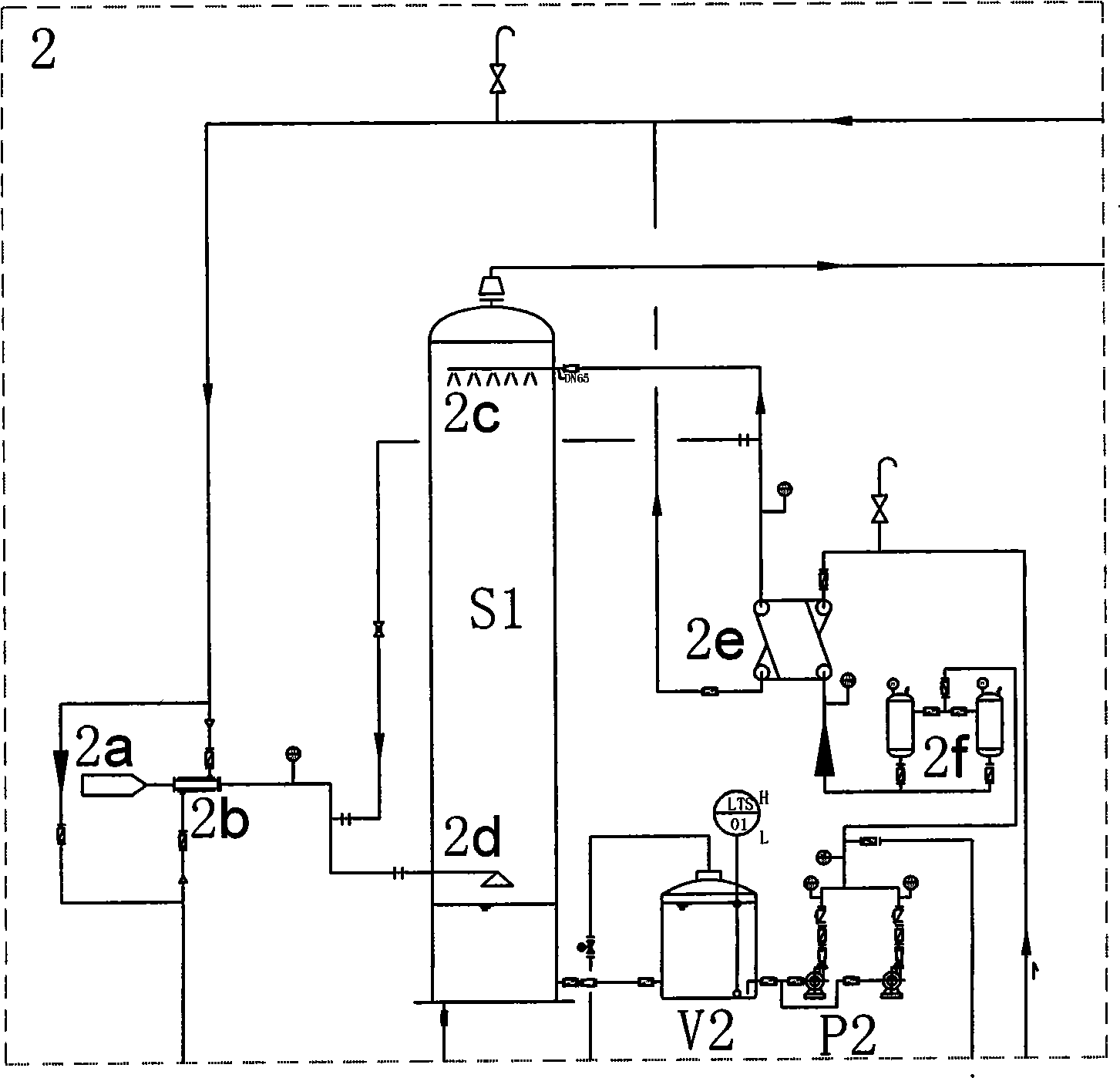

[0036] image 3 The shown dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com