Natural gas vehicle tai-gas clean-up catalyst and preparation method thereof

An exhaust gas purification and natural gas technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of unsuitable natural gas vehicle exhaust, and achieve the effect of increasing methane purification performance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

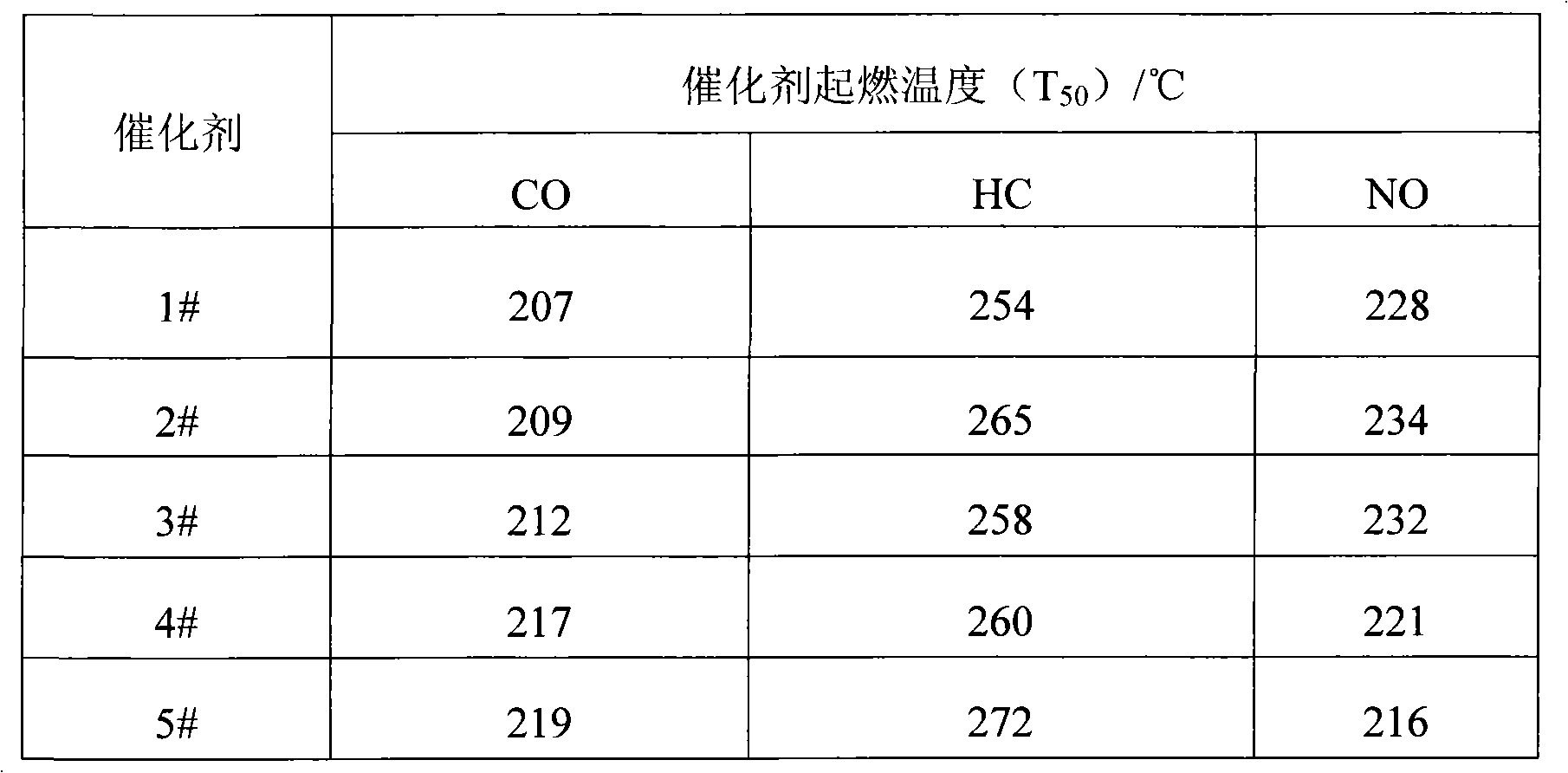

Examples

Embodiment 1

[0030] Weigh 110g of cerium-zirconium solid solution, add 132mL of deionized water, add 12.5mL of rhodium nitrate (8.0g / L) while stirring, and dry at 100°C for 12 hours; the best calcination condition is to calcine at 500°C for 2 hours. Grind the calcined material with 10 g of pseudo-boehmite, then add 156 mL of deionized water and stir, adjust the pH to 4-5 with nitric acid to prepare a coating slurry, and impregnate 1.0 L of ceramic carrier in a vacuum container slurry. After that, it was dried at 120°C for 5 hours for later use.

[0031] Weigh 6.3g of cerium nitrate and 6.6g of lanthanum nitrate, dissolve them in ionized water, add 50g of HZSM-5, stir at room temperature for 24h, dry at 100°C for 12h, and calcinate at 500°C for 4h to obtain modified HZSM-5. Add 55mL deionized water to the modified HZSM-5, add 11.3mL palladium nitrate (80.0g / L) and 6.3mL chloroplatinic acid (80.0g / L) while stirring, and dry at 100°C for 12 hours; calcined for 2 hours. Grind the calcined m...

Embodiment 2

[0033]The reagents used for the modified molecular sieve are cerium nitrate and ferric nitrate, and the rest of the preparation method is the same as in Example 1. It is counted as catalyst 2#.

Embodiment 3

[0035] The reagents used for the modified molecular sieve are cerium nitrate and lanthanum nitrate, and the rest of the preparation method is the same as in Example 1. It is counted as catalyst 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com