Preparation process of wood-rubber functional environment-friendly composite material

A composite material and preparation technology, which is applied to wood processing appliances, flat products, household components, etc., can solve problems such as poor dimensional stability, low density, and easy hydrolysis, and achieve good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

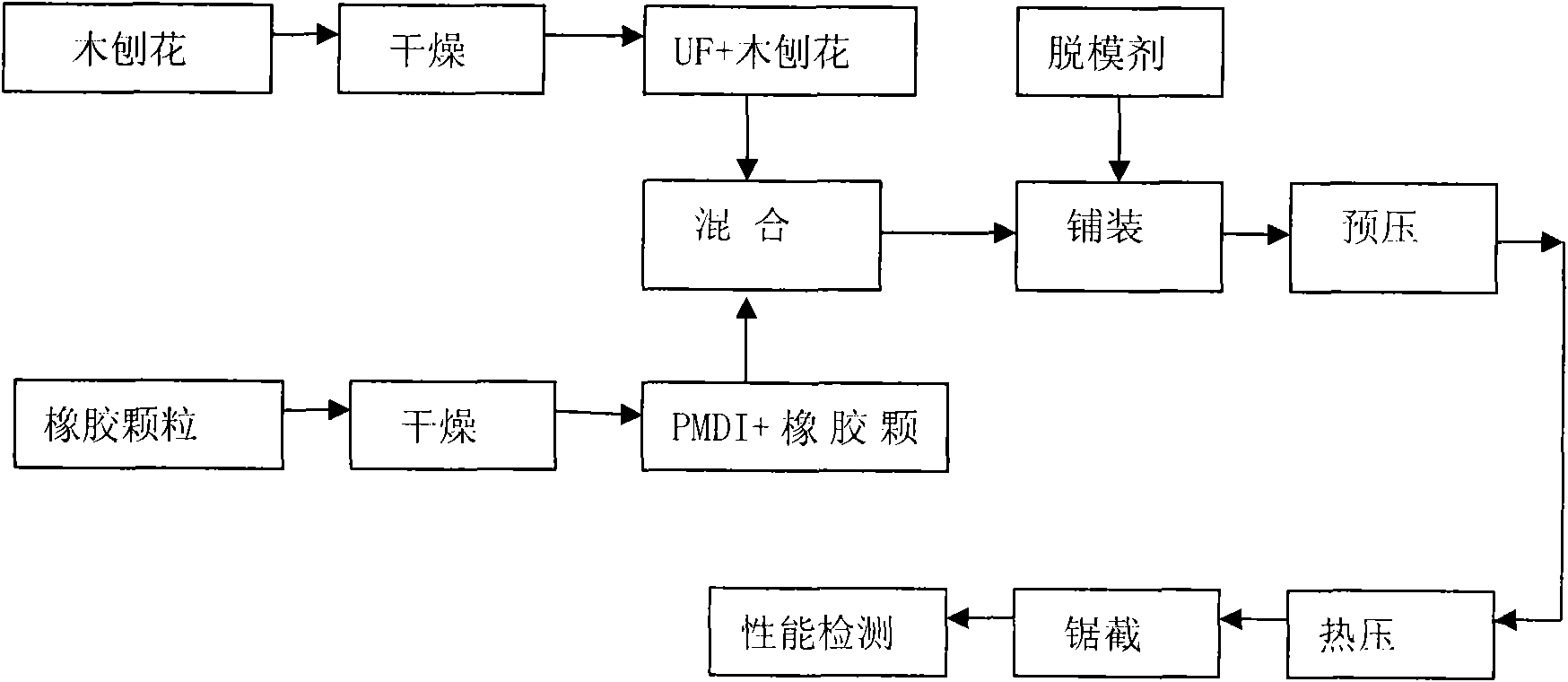

[0019] The manufacturing process of wood-rubber functional environmental protection composite material of the present invention comprises the following steps:

[0020] a. Preparation and drying of wood shavings. Use a wood planer to plan the logs into shavings. The geometry of the shavings is needle-shaped wood shavings for general industrial production: length 3mm-25mm; width 1.0-2.5mm; thickness 0.2-0.8mm, and then use conventional drying to dry the shavings. Dried to a moisture content of 6%-9%.

[0021] b. Mix wood shavings and urea-formaldehyde glue (UF) evenly. The dried wood shavings are mixed evenly with 10% urea-formaldehyde glue (UF).

[0022] c. Preparation and drying of rubber granules. The raw material of rubber granules is taken from ordinary waste automobile tires, and the reinforcing ribs in the waste tires are removed by special machinery to make rubber granules of 1-7mm.

[0023] d. Mix rubber particles with isocyanate (PMDI) evenly. The rubber particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com