Photoinitiator for ultraviolet light radiation solidification, aromatic ketone compound and method of manufacturing the same

A technology of photoinitiator and manufacturing method, which is applied in the field of aromatic ketone compound photoinitiator and aromatic ketone compound manufacture, which can solve the problems of inconsistency in test results, etc., and achieve total reduction, high photoinitiation efficiency, and good solubility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

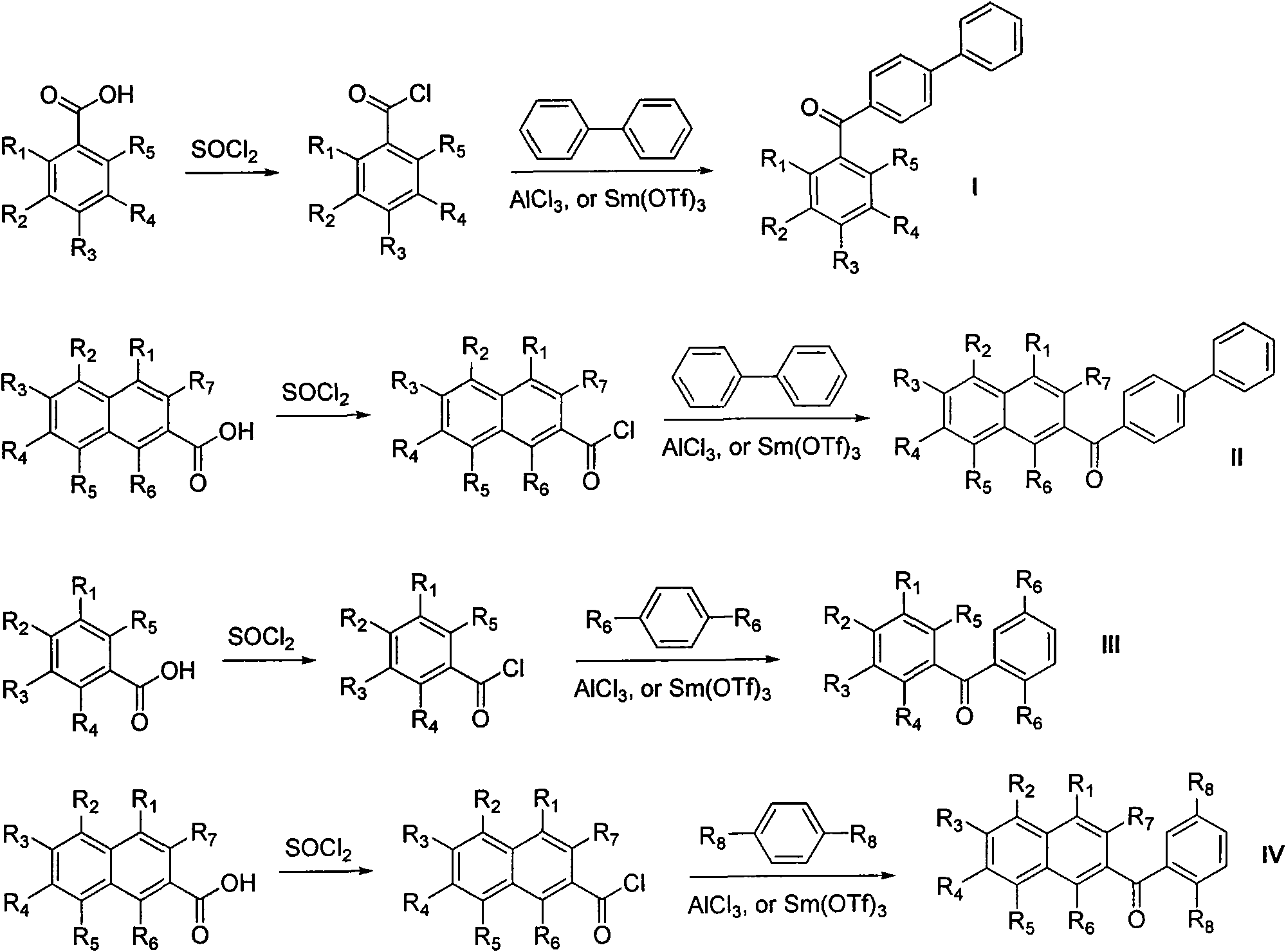

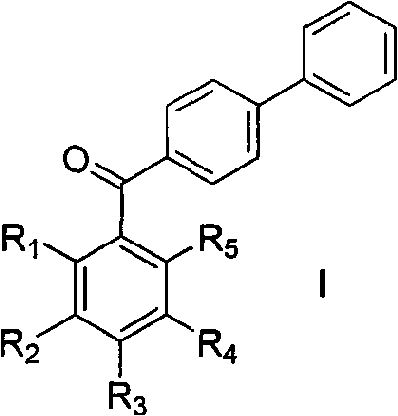

[0054] The present invention discloses substituted aromatic ketone compounds with the following general formulas I-IV.

[0055]

[0056] Among them, R 1 -R 8 Substituents can be P, OP, OC(O)P, C(O)P, C(O)OP, NHP, NP 2 , NHC(O)P, C(O)NHP, or C(O)NP 2 ; And P can be hydrogen, open-chain or ring-closed form of alkyl, or aryl; wherein in the general formula I, III and IV, all R groups are not hydrogen at the same time.

[0057] The compound can be used in photoinitiator applications involving strict restrictions on the total amount of benzene and volatile organic compounds, such as UV-curable ink technology. The compound of the present invention and its composition can be added to any photo-curable material composed of photo-curable resin and monomer, and the photo-curable material can be cured by free radical polymerization after being irradiated by a light source of appropriate wavelength.

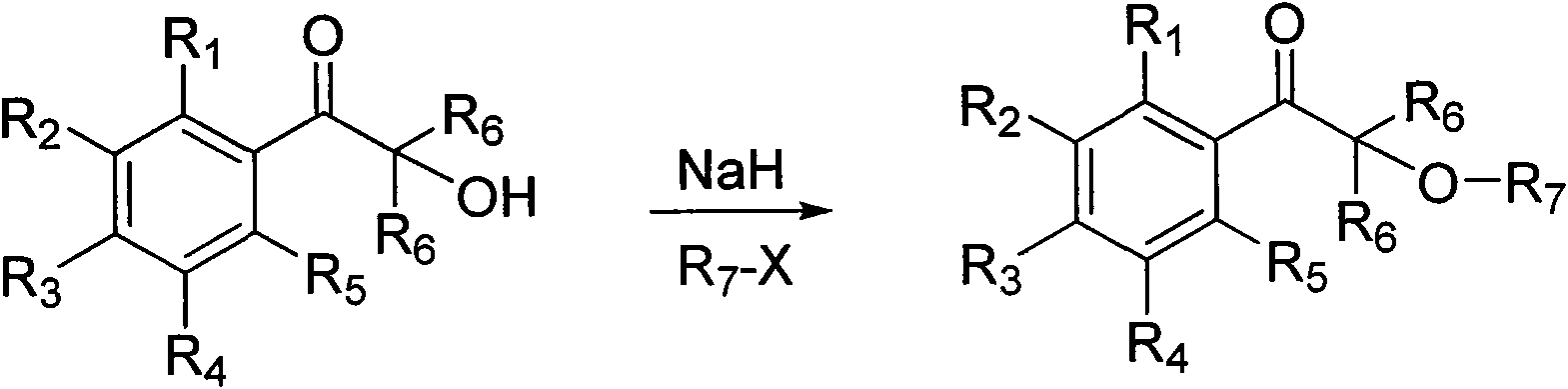

[0058] Please refer to figure 1 , the above compound can be prepared by the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com