Copper and iron modified titanium dioxide pillared bentonite catalyst and preparation method thereof

A titanium dioxide and catalyst technology, applied in the field of catalysts, can solve the problems of catalyst deactivation, blocking downstream pipelines, and short catalyst life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

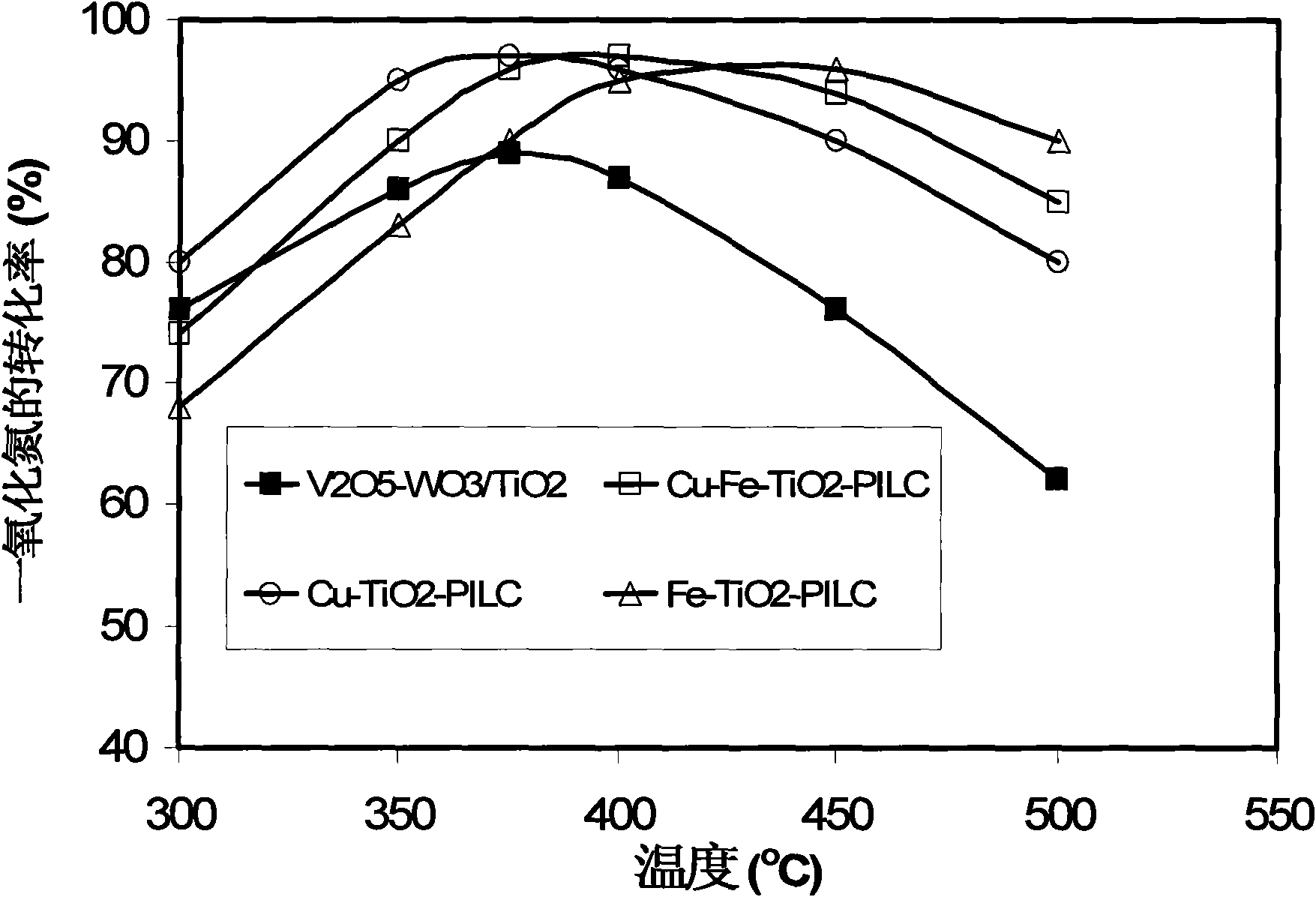

[0034] Example 1 Cu-TiO 2 -PILC

[0035] 1.1 TiO 2 - Preparation of PILC

[0036] Method (1): Anhydrous TiCl 4 Form Ti cross-linking agent solution with alcohol (propanol, isopropanol, methanol, ethanol, butanol, isobutanol or their mixture) solvent, and with 0.1-10wt% bentonite alcohol suspension with titano-soil ratio 2-20mmol / g mixed, hydrothermal reaction at 50-220°C for 1-72 hours. Then filter, wash and dry at 120°C, and finally bake at 350-500°C for 1-24 hours.

[0037] Method (2): First prepare TiCl 4 Disperse in hydrochloric acid aqueous solution to form Ti crosslinking agent solution, the concentration of hydrochloric acid is between 0.1-1.0M. Mix the Ti crosslinking agent solution with 0.1-10wt% bentonite aqueous suspension at a titanium-to-soil ratio (2mmol-50mmol) / g, age for 1-72 hours, then filter, wash and dry at 120°C, and finally dry at 350- Baking at 500°C for 1-24 hours.

[0038] 1.2 Cu-TiO 2 - Preparation of PILC

[0039] Using the traditional aqu...

Embodiment 2

[0040] Example 2 Fe-TiO 2 -PILC

[0041] 2.1 TiO 2 The preparation of -PILC is the same as 1.1.

[0042] 2.2 Fe-TiO 2 - Preparation of PILC

[0043] Applying the traditional aqueous ion exchange method, TiO 2 - PILC was added to an aqueous iron salt solution (solid / liquid = 1 g: 10-2000 ml), and kept stirring for 1-72 hours. Sources of iron salt precursors include ferric sulfate, ferrous sulfate, ferric nitrate, ferric chloride, ferrous chloride, and ferric acetate. The concentration of the iron salt solution is between 0.01-5.0M. Then filter, wash, dry at 120°C, and finally bake at 350-500°C for 1-24 hours.

Embodiment 3

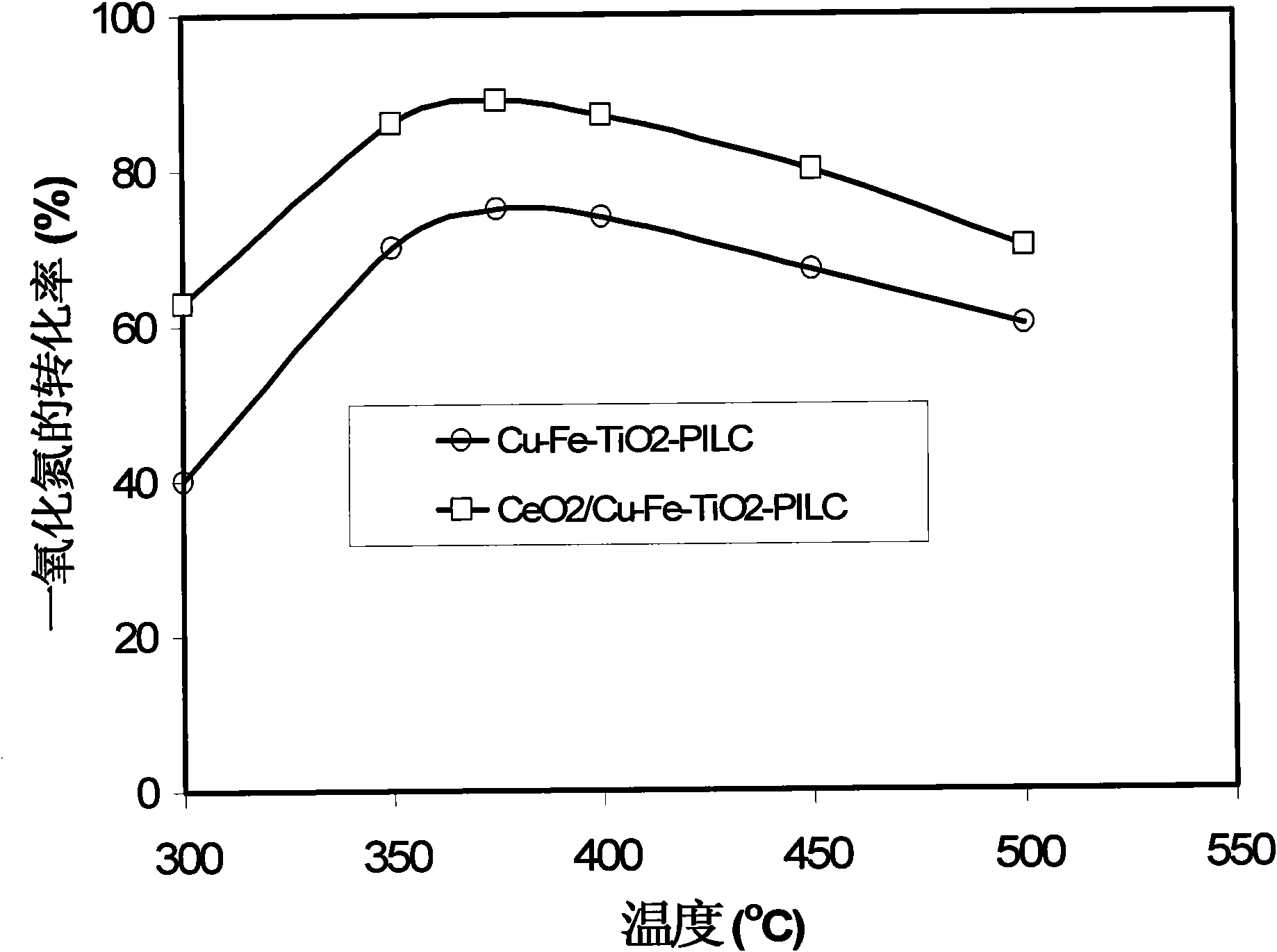

[0044] Example 3 Cu-Fe-TiO 2 -PILC

[0045] 3.1 TiO 2 The preparation of -PILC is the same as 1.1.

[0046] 3.2 Cu-Fe-TiO 2 - Preparation of PILC

[0047] Using the traditional aqueous solution ion exchange method, the TiO 2 - PILC was added to copper and iron salt aqueous solution (Cu / Fe molar ratio = 0.01-100:1, solid / liquid = 1 g / 10-2000 ml), and kept stirring for 1-72 hours. The concentration of the total copper and iron salt solution is between 0.01-5.0M. Then filter, wash, dry at 120°C, and finally bake at 350-500°C for 1-24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com