Preparation of LiMnO2 nano-sheet and application thereof in lithium battery

A nanosheet and lithium battery technology, applied in the field of nanomaterials, can solve the problems of no nanosheet patent report, complex preparation method, harsh conditions, etc., and achieve the effects of significant economic value, simple preparation method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] Mix lithium hydroxide and manganese trioxide according to a mol ratio of 5-15:1, add deionized water so that the concentration of lithium hydroxide in the solution is 2mol / L, stir it fully with a magnetic stirrer and transfer it to poly LiMnO can be prepared by hydrothermally reacting at 200°C for three hours in a stainless steel reaction kettle with vinyl fluoride substrate, washing and filtering with water for 2 to 3 times, and vacuum drying at 70°C for 10 hours. 2 Nanosheets.

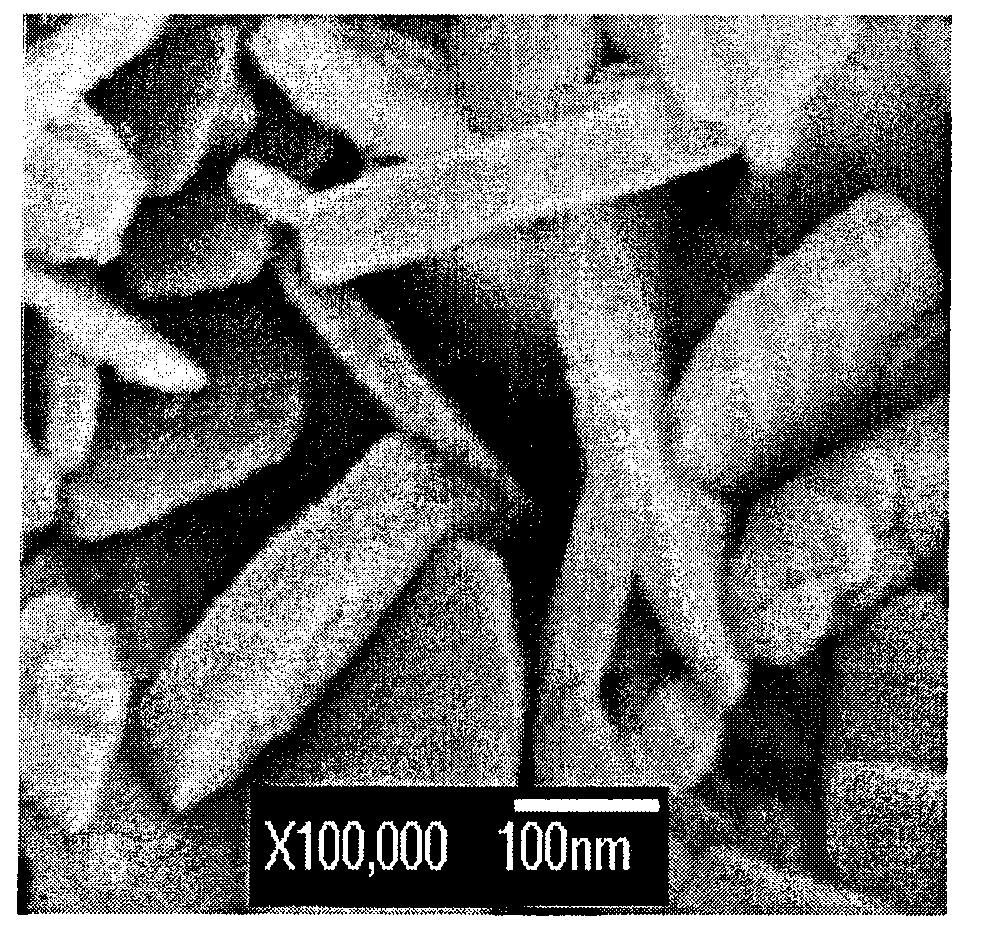

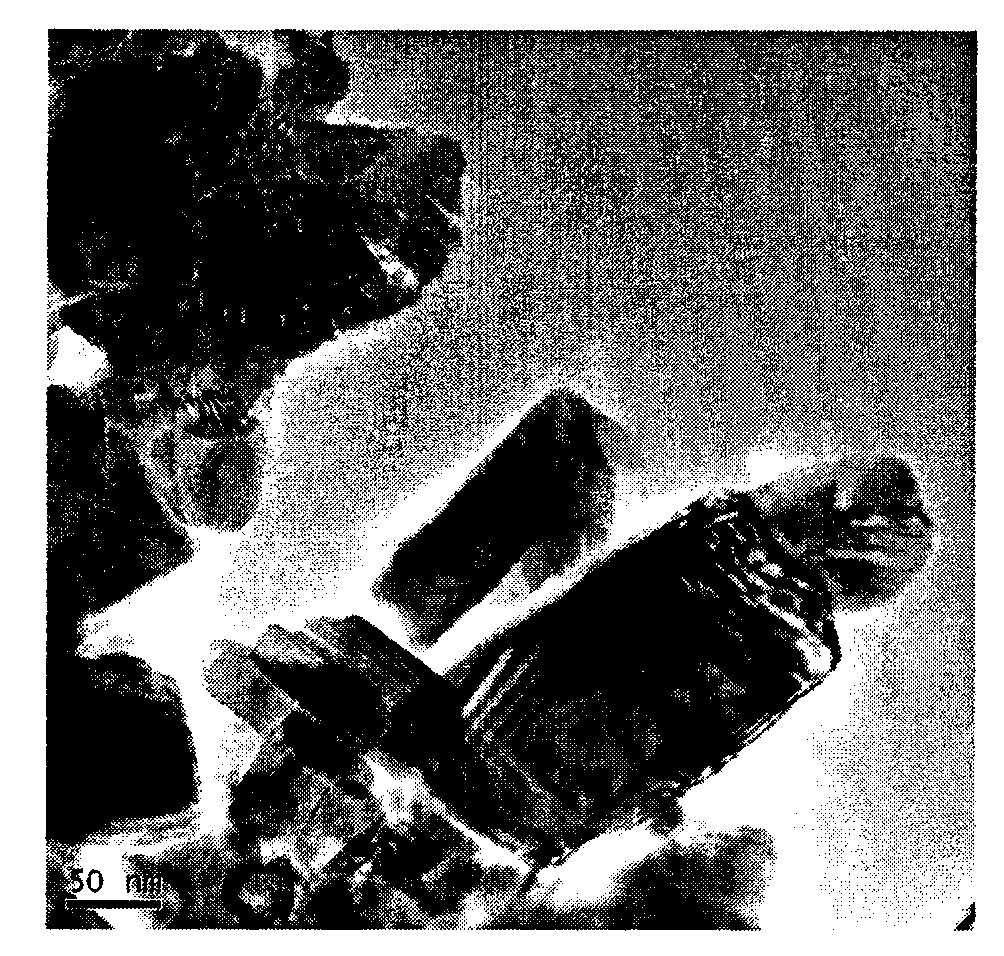

[0014] From figure 1 and figure 2 It can be clearly seen that the LiMnO of the present invention 2 Nanosheets are stacked by many thin sheets with a thickness of about several nanometers, and the thickness of the nanosheets is about 40nm.

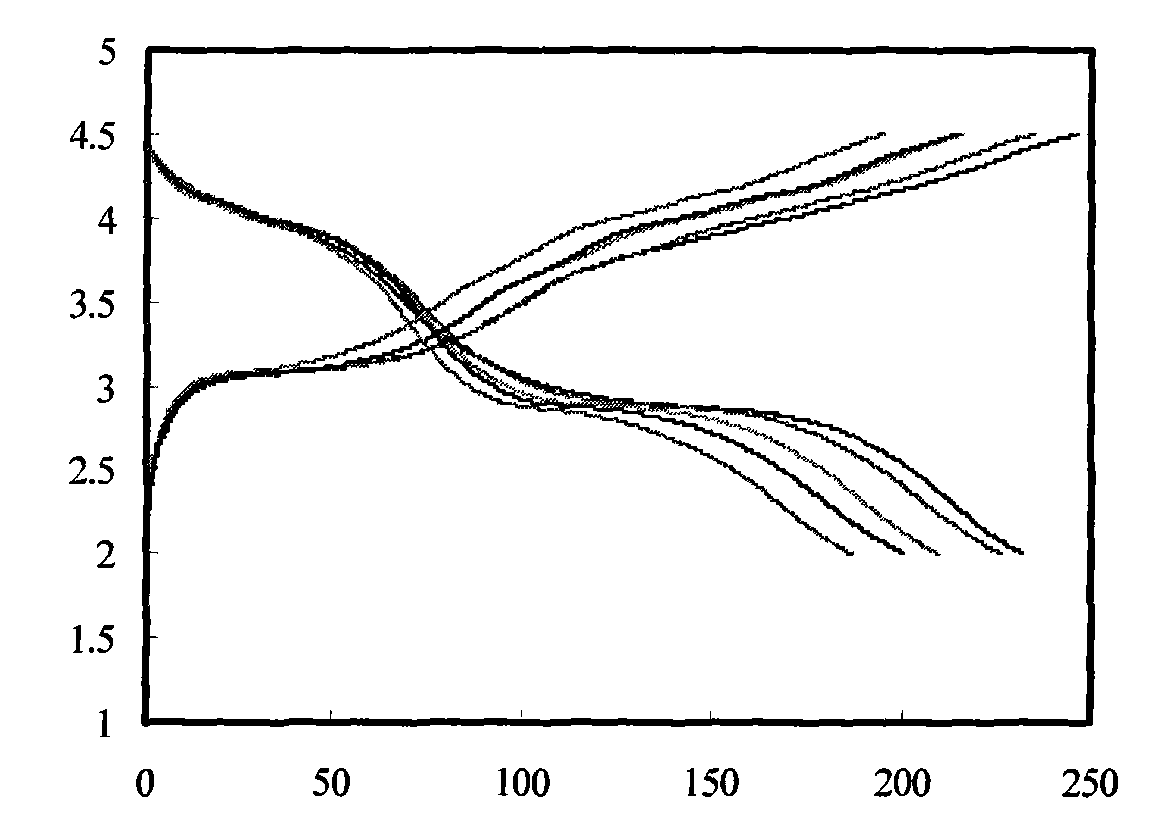

[0015] LiMnO 2 Application of Nanosheets in Lithium Batteries: Assembly of the Lithium Batteries: By Mass Ratio LiMnO 2 Nanosheets: acetylene black: polyvinylidene fluoride (PVDF) = 75:15:10 mixed and ground and evenly coated on a circular aluminum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com