Method for preparing zirconium hydride

A zirconium hydride, oxidizing technology, applied in the direction of transition element hydride, etc., can solve the problems of micro-cracks in the matrix, easy cracking and peeling of the film layer, and difficulty in the hydrogen barrier film layer. Effects of the hydrogen problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

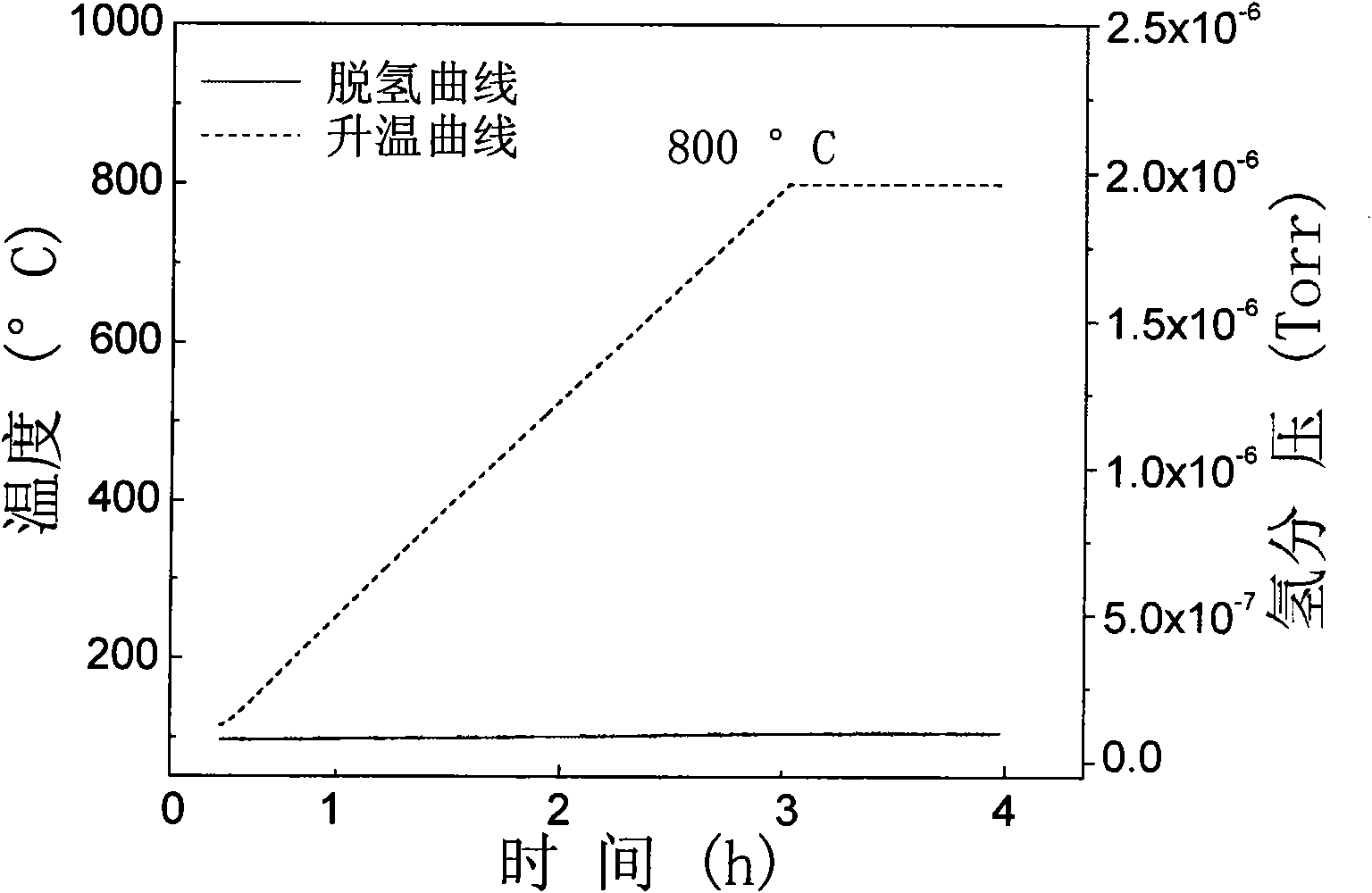

[0029] Cut zirconium hydride with a hydrogen-zirconium atomic ratio of about 1.8 into a Φ20mm×10mm cylindrical sample. The samples were ultrasonically cleaned with acetone for 15 minutes and then dried.

[0030] The pretreated zirconium hydride sample is placed in a vacuum tube resistance furnace for high-temperature thermal oxidation treatment, so that a zirconium oxide hydrogen barrier film layer is formed on the surface of the zirconium hydride. The specific steps are as follows: put the zirconium hydride sample into a stainless steel crucible, then put it into a vacuum tube resistance furnace, start the mechanical pump, vacuumize, extract the air in the crucible, and then inject CO into the crucible. 2 To 0.1MPa, start heating. The heating rate during the heating process is 1°C / min. When the temperature reaches 350°C, keep it warm for 60 hours, then cut off the power supply, and cool down with the furnace to form a zirconia hydrogen barrier film layer.

[0031] The oxidi...

Embodiment 2

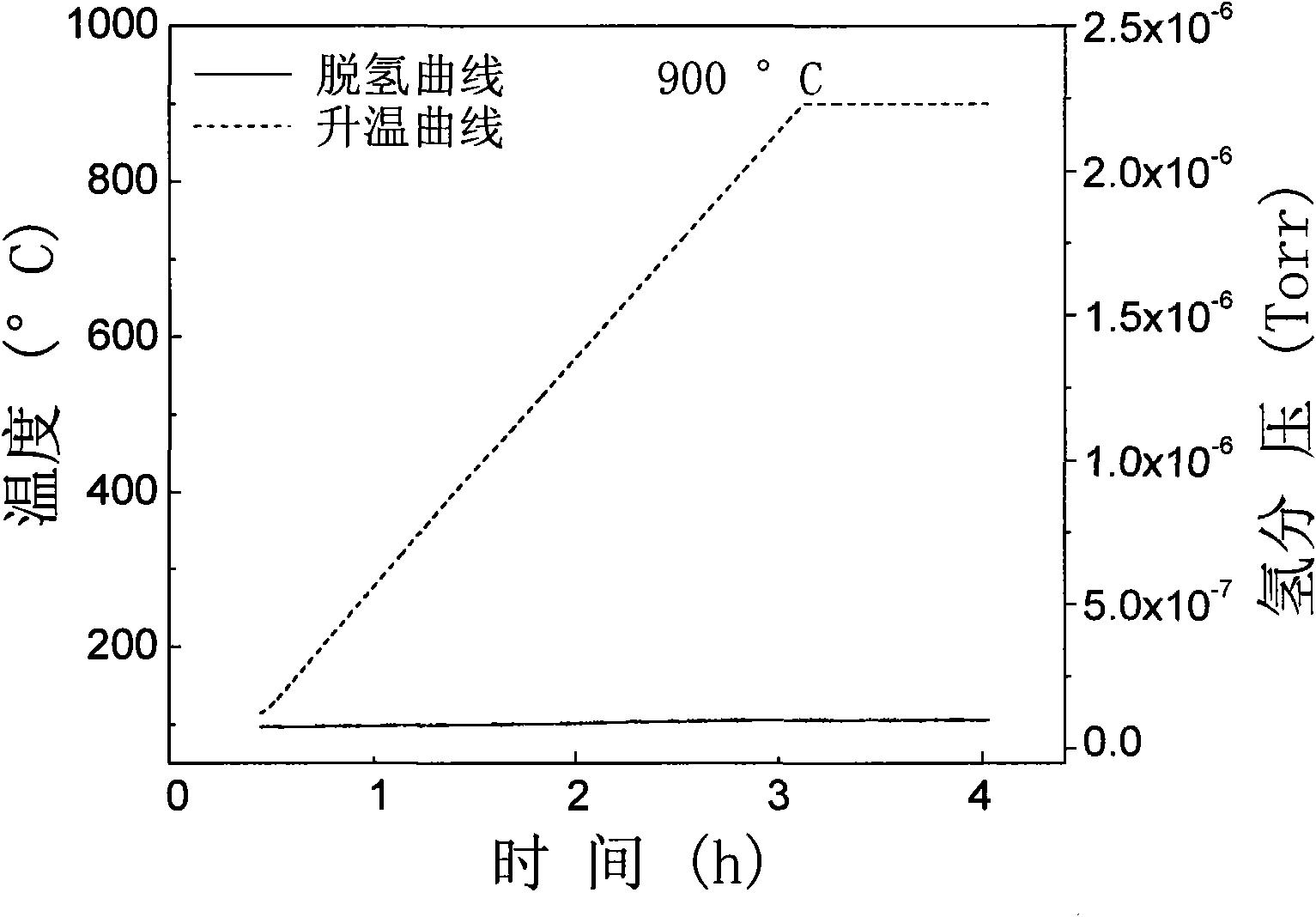

[0033] Cut zirconium hydride with a hydrogen-zirconium atomic ratio of about 1.8 into a Φ20mm×10mm cylindrical sample. The samples were ultrasonically cleaned with acetone for 20 minutes and then dried.

[0034] The pretreated zirconium hydride sample is placed in a vacuum tube resistance furnace for high-temperature thermal oxidation treatment, so that a zirconium oxide hydrogen barrier film layer is formed on the surface of the zirconium hydride. The specific steps are as follows: put the zirconium hydride sample into a stainless steel crucible, then put it into a vacuum tube resistance furnace, start the mechanical pump, vacuumize, extract the air in the crucible, and then inject CO into the crucible. 2 To 0.1MPa, start heating. The heating rate during the heating process is 5°C / min. When the temperature reaches 600°C, keep it warm for 30 hours, then cut off the power supply, and cool down with the furnace to form a zirconia hydrogen barrier film layer.

[0035] The oxidi...

Embodiment 3

[0037] Cut zirconium hydride with a hydrogen-zirconium atomic ratio of about 1.8 into a Φ20mm×10mm cylindrical sample. The samples were ultrasonically cleaned with acetone for 20 minutes and then dried.

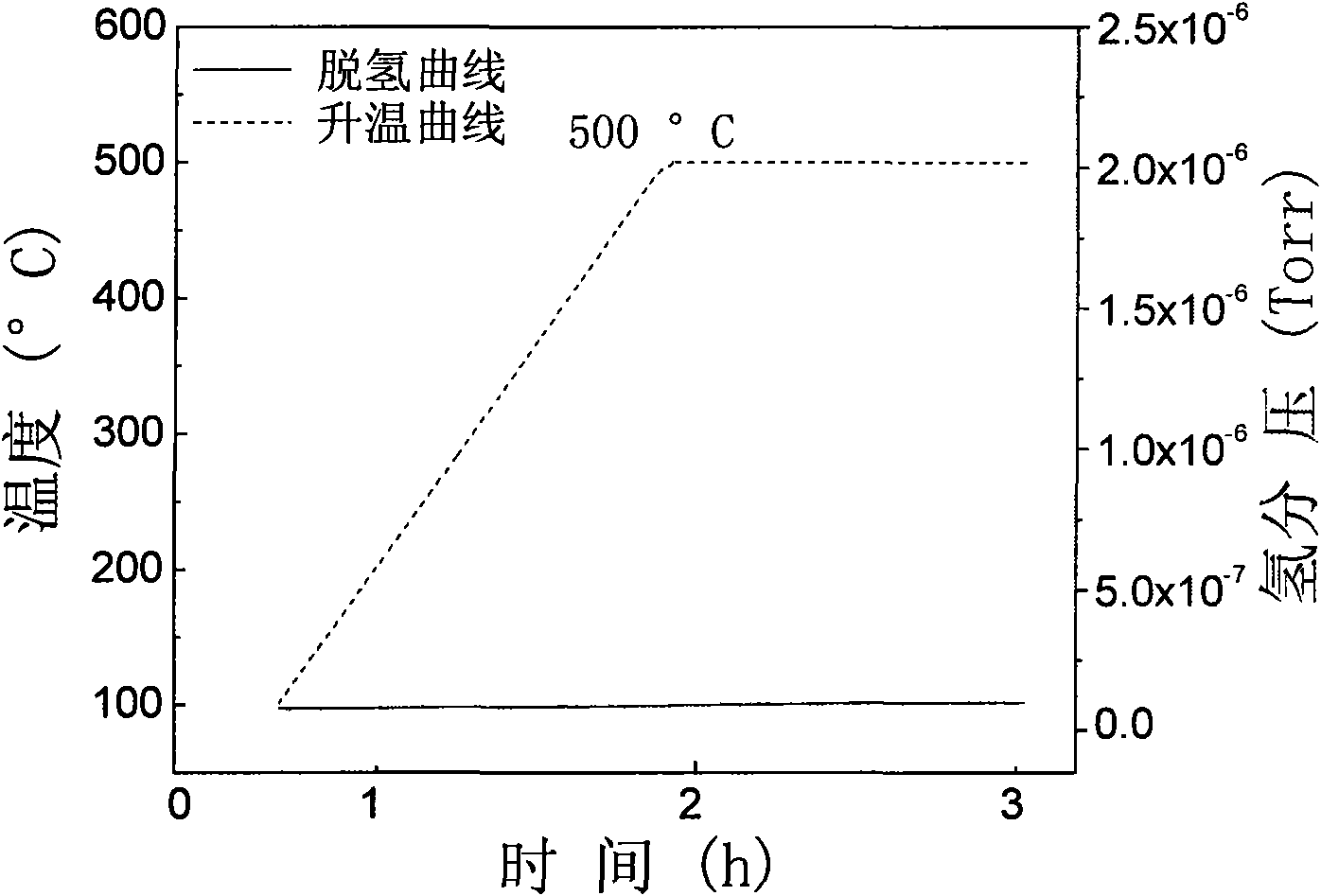

[0038] The pretreated zirconium hydride sample is placed in a vacuum tube resistance furnace for high-temperature thermal oxidation treatment, so that a zirconium oxide hydrogen barrier film layer is formed on the surface of the zirconium hydride. The specific steps are as follows: put the zirconium hydride sample into a stainless steel crucible, then put it into a vacuum tube resistance furnace, start the mechanical pump, vacuumize, extract the air in the crucible, and then inject CO into the crucible. 2 To 0.1MPa, start heating. The heating rate during the heating process is 2°C / min. When the temperature reaches 500°C, keep it warm for 40 hours, then cut off the power supply, and cool down with the furnace to form a zirconia hydrogen barrier film layer.

[0039] The oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com