Method and device for preparing silicon nanoparticles by utilizing plasma body

A silicon nanoparticle and plasma technology, applied in the field of nanomaterials, can solve problems such as gaps and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

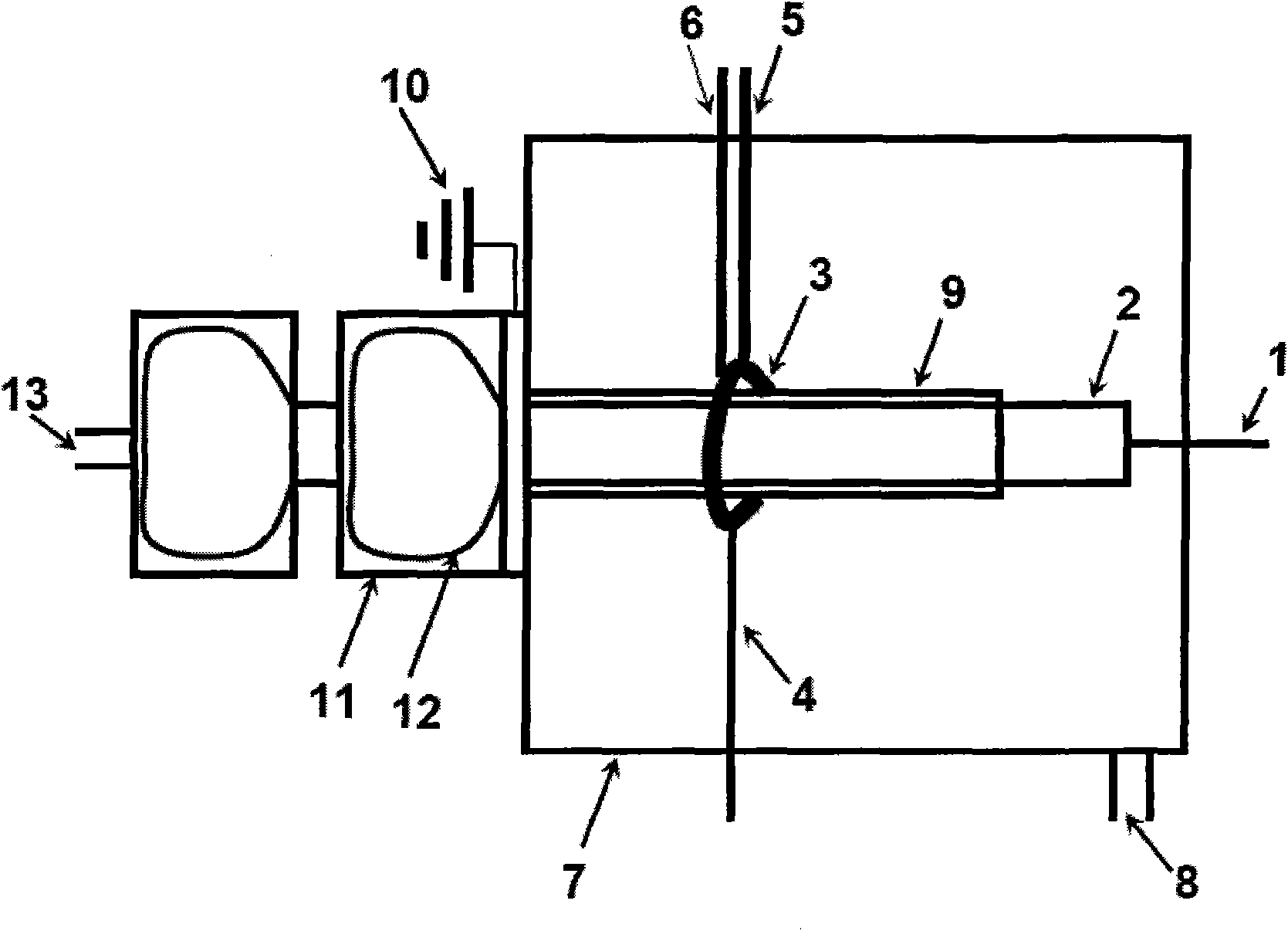

[0052] See figure 1 , The device of the present invention for preparing silicon nanoparticles using plasma includes a tubular plasma chamber 2. One end of the plasma chamber 2 is connected to the gas inlet pipe 1, and the other end is connected to a collector. The collector consists of a stainless steel collection bottle 11 and a built-in collection bag. In this embodiment, two collectors are connected in series with each other. The latter collector is connected to a vacuum pipeline interface 13 and connected to a vacuum pump. The collector has a ground wire 10.

[0053] The plasma chamber 2 is jacketed with a heating jacket 9 for heating the plasma chamber 2, and an excitation device for exciting plasma is provided outside the heating jacket 9.

[0054] The excitation device selects a radio frequency power supply to excite the plasma, including a ring-shaped radio frequency electrode 3 made of metal copper arranged outside the plasma cavity and connected to the radio frequency m...

Embodiment 2~4

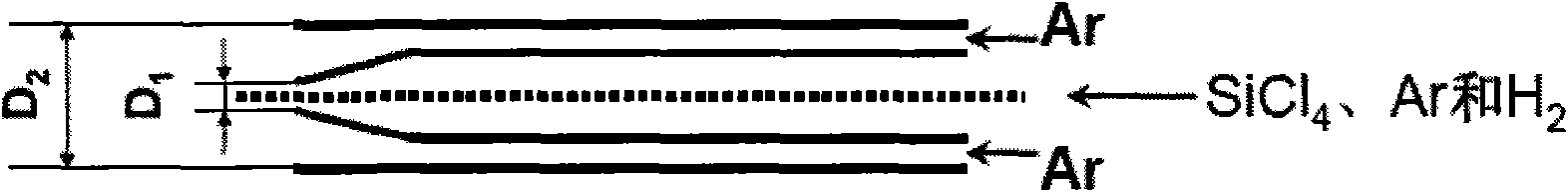

[0061] The device of Example 1 was used to prepare silicon nanoparticles. 5 slm of silicon tetrachloride gas, 11 slm of hydrogen, and 150 slm of argon were mixed and then entered into the inner tube of the inlet pipe made of quartz. Enter between the inner and outer tubes. Inner diameter of outer tube D 2 With the inner diameter of the inner tube D 1 The ratio is 15:1.

[0062] The air pressure in the quartz plasma chamber is adjusted to 1.5×10 by a vacuum pump connected to the collector 4 Pa. The power of the microwave (2.4 GHz) applied to the plasma is 2.5 kW (Example 2), 3 kW (Example 3), or 4 (Example 4) kW. The distance between the microwave resonator and the stainless steel coupling is 15 cm. The temperature of the heating jacket is set at 200°C. The generated silicon nanoparticles are continuously collected by two collection bags made of nickel wire mesh.

[0063] X-ray diffraction (XRD) measurement (see Figure 4 ) Indicates that the prepared silicon nanoparticles are cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com