Method and device for contacting two non miscible liquids without mixing them

A liquid and liquid reaction technology, applied in the field of chemical separation and contact technology, can solve problems such as degradation, and achieve the effects of low energy consumption, easy remote operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

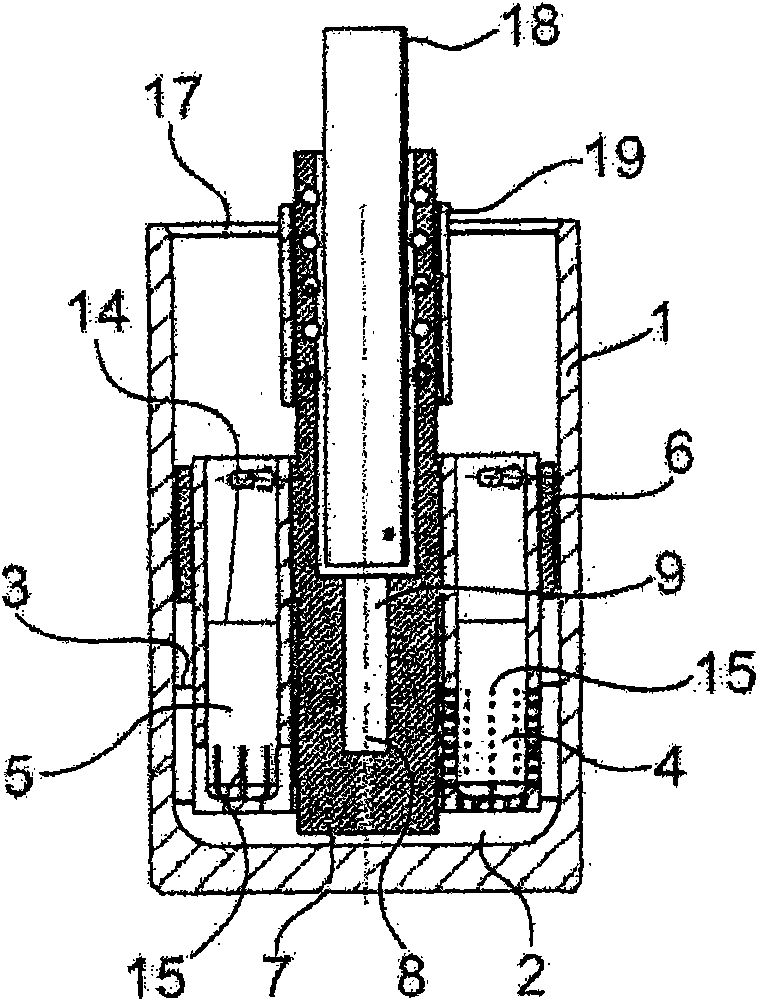

[0173] NdF in the from solution 3 During the test for the recovery of rubidium (Nd), the and Figure 1~4 The associated extraction device.

[0174] Operation mode includes 10g NdF 3 Dissolved to 300g LiF / AlF 3 in.

[0175] The salt mixture thus obtained is placed in a graphite crucible with a volume of 1 liter, and then melted in a shaft furnace at 700°C to 800°C.

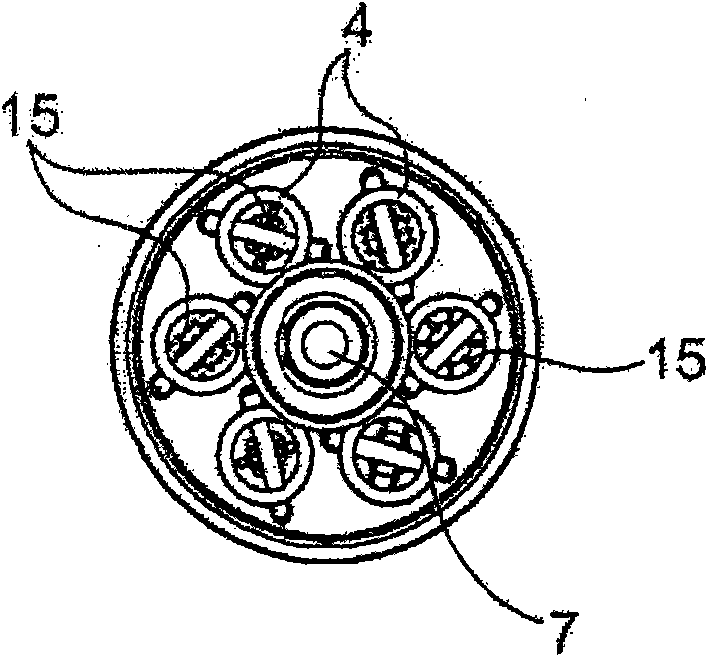

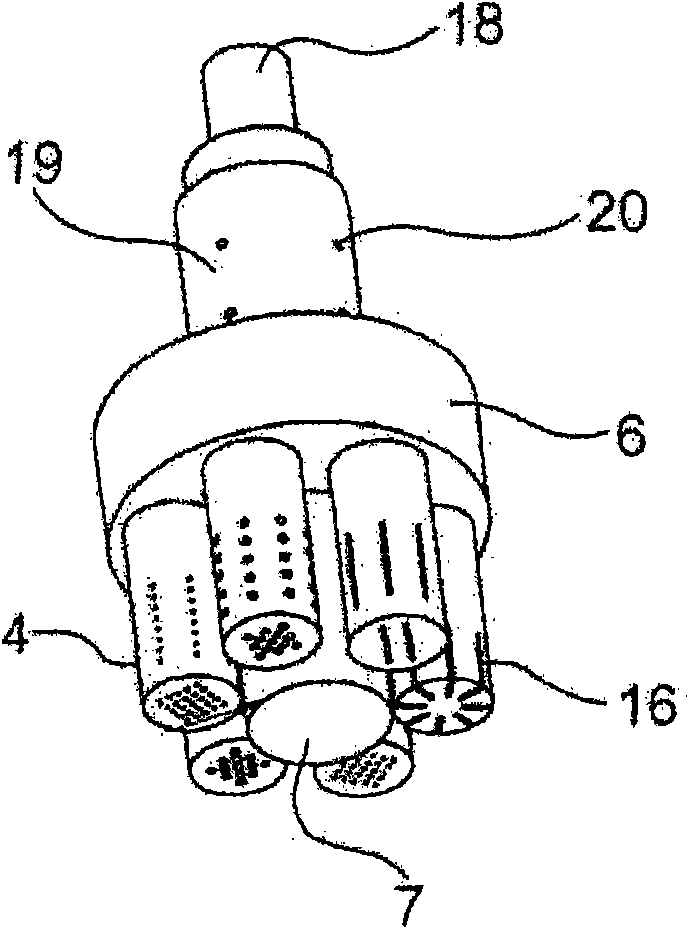

[0176] For the extraction medium, 100g Al is placed in six perforated, perforated baskets with a volume of 0.14 liters, the pore geometry of the basket corresponds to image 3 , And then vacuum melting the salt at 800°C.

[0177] Then the contact between the molten metal and the salt medium takes place in a rough vacuum, after which argon gas covers the inside of the furnace at atmospheric pressure to avoid any excessive evaporation of the salt.

[0178] For this test, the extraction time is 24 hours of contact between the two media.

[0179] After 24 hours, the turntable support with six baskets was slowly raised at a ...

Embodiment 2

[0185] Three more experiments are needed to test the possibility of removing the turntable from the salt without losing aluminum, which involve a melting / cooling cycle for aluminum contained in a perforated, perforated basket.

[0186] These experiments were performed on crucibles containing aluminum whose height was 10% lower than the maximum height calculated from Equation 1 depending on the geometry of the pores.

[0187] The height of Al thus used is between 1.5 cm and 8 cm. The weight loss measurement performed for each crucible showed a weight change of about 0.5%. This good result confirms the possibility of keeping liquid aluminum in an argon atmosphere without the hydrostatic back pressure of molten salt.

[0188] After three melting / cooling cycles, no damage to the crucible containing aluminum was observed. Therefore, the design of the system makes it possible to achieve good mechanical characteristics facing the problem of uneven expansion (thermal cycle) of materials. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com