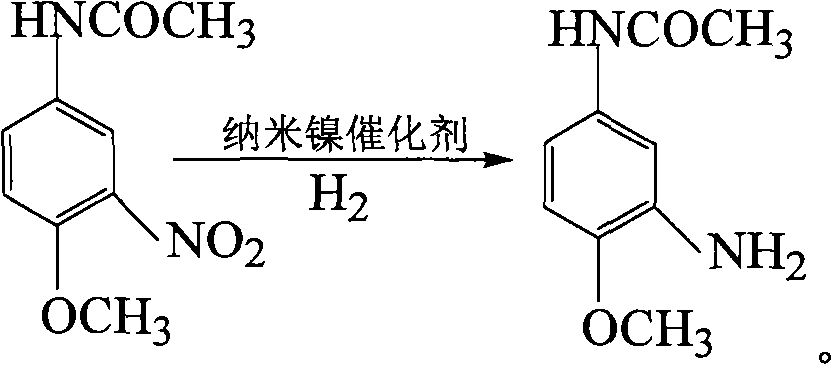

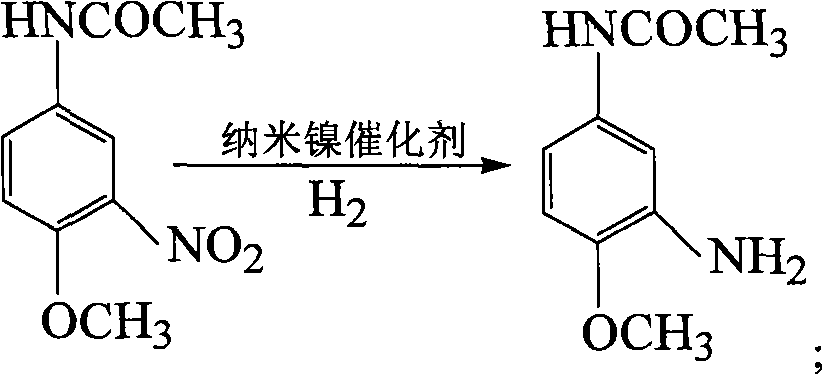

Method for synthesizing 3-amino-4-methacetin by catalytic hydrogenation

A methoxyacetanilide, catalytic hydrogenation technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid amides, etc. High raw material conversion rate and product selectivity, environmental friendliness, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Nickel oxalate and the surfactant polyethylene glycol 200 that consumption is 1wt% of nickel oxalate are ultrasonically dispersed in 50ml ethanol solution respectively, then both are added in the three-neck round-bottomed flask of 250ml respectively, in the setting of magnetic stirrer Mix with stirring (60°C). Then, add 1 mol / L NaOH dropwise to adjust the pH value between 11-12. After reacting for 1 hour, use a constant pressure funnel to drop the reducing agent hydrazine hydrate with a concentration of 0.35 mol / L. Into the above-mentioned reducing agent-surfactant mixed ethanol solution, the time for dropping is 30min. The dropwise reaction mixture was stirred at 80° C. for 8 h to obtain a nano-nickel catalyst. Weigh 0.3g of the above-mentioned prepared nano-nickel catalyst, 30g of 3-nitro-4-methoxy-acetanilide, the amount of catalyst is 1wt% of the raw material, put it into a 1000ml reactor, add 200ml of absolute ethanol, and start Stir. Nitrogen was introduced for...

Embodiment 2

[0021] Nickel oxalate and the surfactant polyethylene glycol 2000 that consumption is 1wt% of nickel oxalate are ultrasonically dispersed in 50ml ethanol solution respectively, then both are added in the three-neck round-bottomed flask of 250ml respectively, in the setting of magnetic stirrer Mix with stirring (60°C). Then, add 1 mol / L NaOH dropwise to adjust the pH value between 11-12. After reacting for 1 hour, use a constant pressure funnel to drop the reducing agent hydrazine hydrate with a concentration of 0.35 mol / L. Into the above-mentioned reducing agent-surfactant mixed ethanol solution, the time for dropping is 30min. The dropwise reaction mixture was stirred at 80° C. for 8 h to obtain a nano-nickel catalyst. Weigh 0.3g of the above-mentioned prepared nano-nickel catalyst, 30g of 3-nitro-4-methoxy-acetanilide, the amount of catalyst is 1wt% of the raw material, put it into a 1000ml reactor, add 200ml of absolute ethanol, and start Stir. Nitrogen gas was introduce...

Embodiment 3

[0023] Nickel oxalate and the surfactant polyethylene glycol 6000 that consumption is 1wt% of nickel oxalate are ultrasonically dispersed in 50ml ethanol solution respectively, then both are added in the three-neck round-bottomed flask of 250ml respectively, in the magnetic stirrer Mix with stirring (60°C). Then, add 1 mol / L NaOH dropwise to adjust the pH value between 11-12. After reacting for 1 hour, use a constant pressure funnel to drop the reducing agent hydrazine hydrate with a concentration of 0.35 mol / L. Into the above-mentioned reducing agent-surfactant mixed ethanol solution, the time for dropping is 30min. The dropwise reaction mixture was stirred at 80° C. for 8 h to obtain a nano-nickel catalyst. Weigh 0.3g of the above-mentioned prepared nano-nickel catalyst, 30g of 3-nitro-4-methoxy-acetanilide, the amount of catalyst is 1wt% of the raw material, put it into a 1000ml reactor, add 200ml of absolute ethanol, and start Stir. Nitrogen gas was introduced for 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com