Novel process for all-component high-added-value clean utilization of waste circuit boards

A waste circuit board and full-component technology, which is applied in the field of high-value clean utilization of waste circuit boards with full components, can solve the problem of inability to disassemble electronic components, circuit boards, recovery of metals such as lead and tin, and production and processing costs. High problems, to achieve the effect of being conducive to centralized treatment, improving copper purity, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

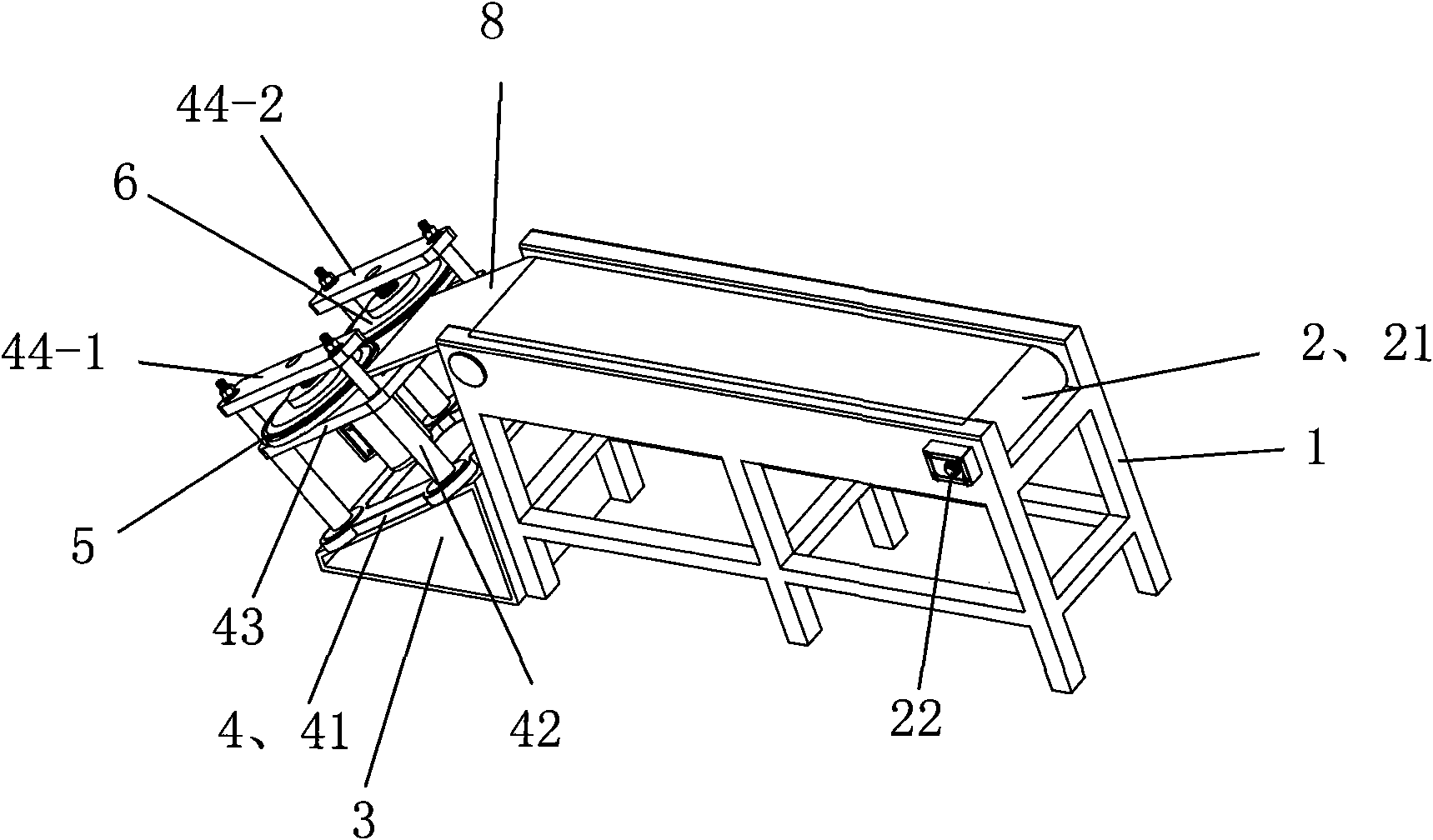

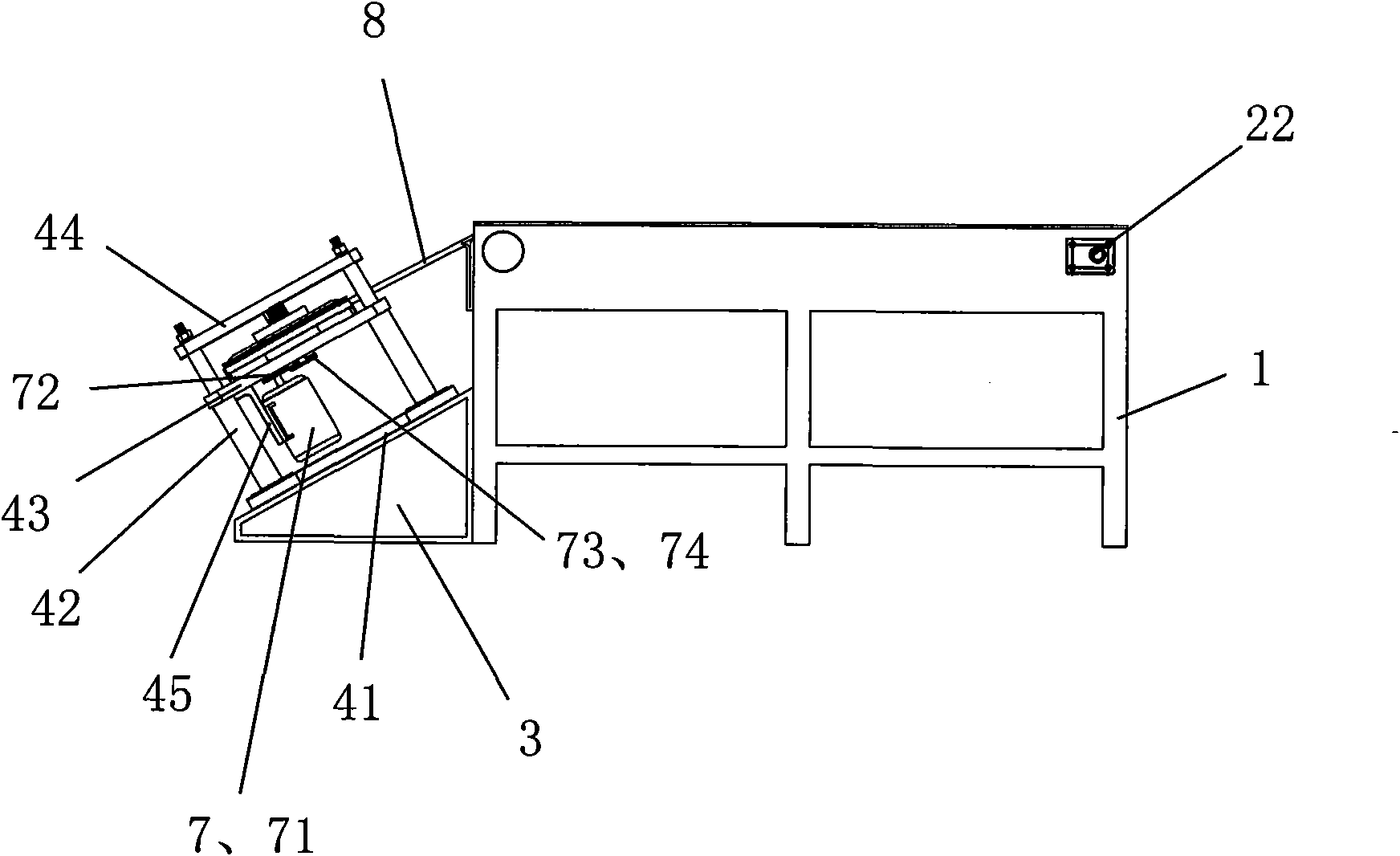

[0042] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

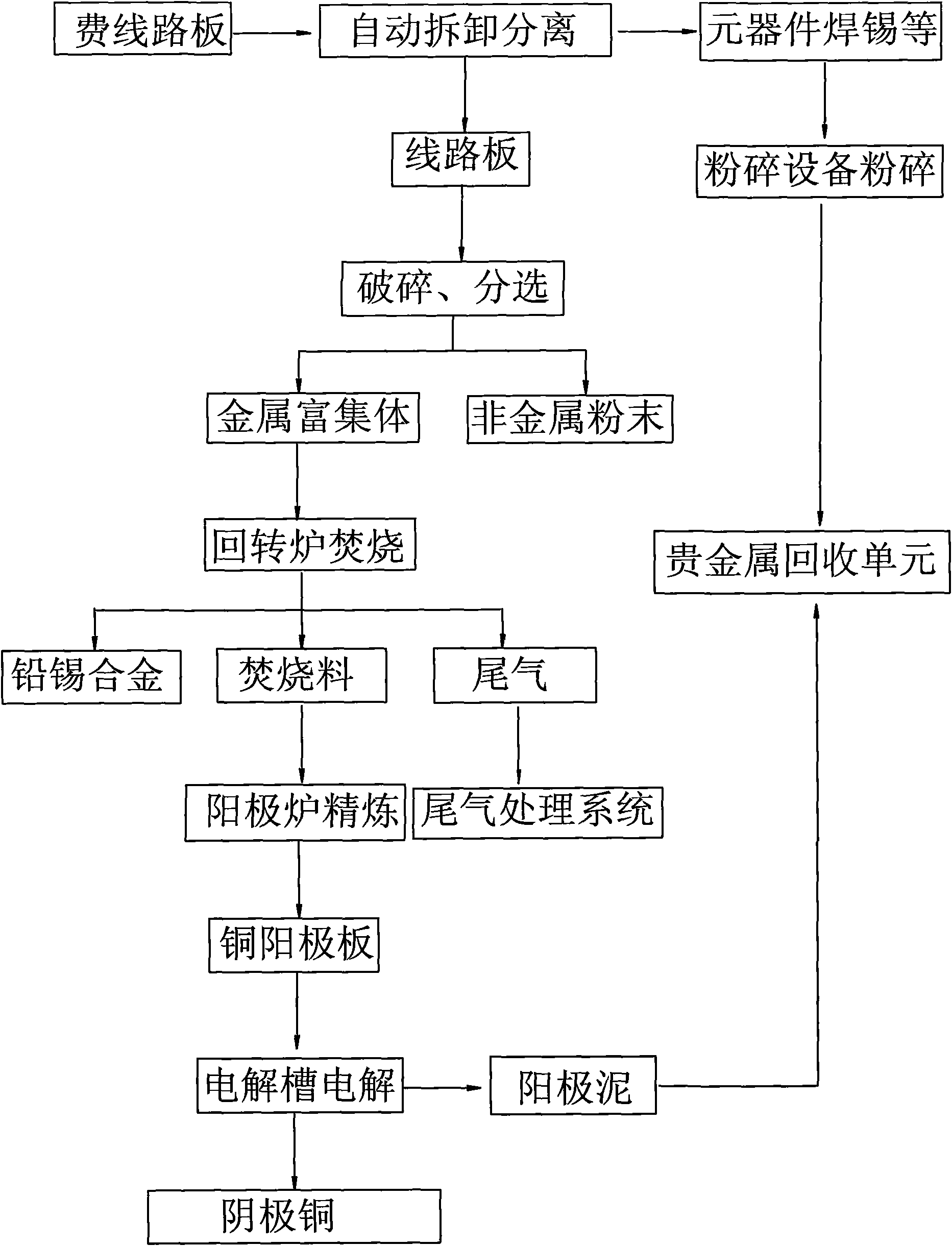

[0043] Such as figure 1 As shown: the new high-value cleaning and utilization process of waste circuit boards of the present invention includes the following steps: (a) the waste circuit boards with components are separated from the circuit boards by an automatic dismantling and sorting device ;Using the shearing pulverizer to crush components as raw materials for precious metal deep processing units, which is conducive to the centralized treatment of gold, silver, platinum, palladium and other precious metals on components, and can also reduce components from being broken with waste circuit boards, The loss of precious metals caused by crushing and sorting; (b) using a pneumatic crusher to crush the circuit board, the crushed powder is screened through 2mm, and the powder below 2mm is separated by sorting to obtain rough copper po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com