Fire-retardant polyethylene cable material with mould-proof function and preparation method thereof

A technology of flame-retardant polyethylene and cable materials, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of reducing the use value of cable materials, the performance of antibacterial cable materials, and low application value, so as to improve the use value and prolong the use Longevity, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the names of the components and the weight of the components as follows:

[0028] High-density polyethylene resin (melt index is 0.25g / 10min, produced by Sinopec) 70Kg

[0029] Linear low-density polyethylene resin (melt index is 2.5g / 10min, produced by Sinopec) 30Kg

[0030] Carbon black (produced by Degussa, the brand is 900L) 2.85Kg

[0031] Flame retardant (No. 8010 flame retardant, produced by Yabao Company) 65Kg

[0032] Lubricant (PE wax, produced in Pudong Fufa) 6Kg

[0033] Antioxidant (Irganox 1010 type antioxidant, produced by Swiss Ciba Company) 2Kg

[0034] Antibacterial agent (IRGAGUARD B 5000 antibacterial agent, produced by Ciba, Switzerland) 2Kg

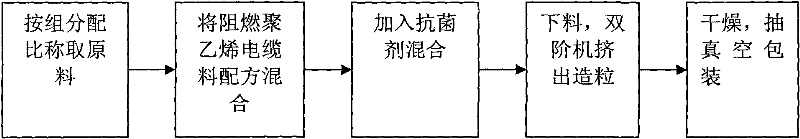

[0035] The flow chart of the preparation method is as figure 1 Shown: First mix the resin granules in the anti-mold and flame-retardant polyethylene cable material formula evenly, then pour in the powder, and disperse evenly with the granules, then add oil, so that the oil is evenly distribut...

Embodiment 2

[0040] Each component name and each component parts by weight ratio are:

[0041] HDPE resin 65Kg

[0042] Linear Low Density Polyethylene Resin 35Kg

[0043] Carbon black 2.75Kg

[0044] Flame retardant 59Kg

[0045] Lubricant 5.4Kg

[0046] Antioxidant 1.7Kg

[0047] Antibacterial agent 1.8Kg

[0048] The preparation method is as follows: first mix the resin pellets in the anti-mildew and flame-retardant polyethylene cable material formula evenly, then pour the powder, disperse evenly with the pellets, and then add oil, so that the oil is evenly distributed on the surface of the pellets, and mixed with the powder Coat the pellets evenly with the materials, mix in the kneading pot for 5 minutes; then extrude and granulate in the temperature range of 100-140°C; finally, dry with hot air at 85°C for 3 hours, pack them in bags in time, and fully vacuumize Package.

Embodiment 3

[0050] Each component name and each component parts by weight ratio are:

[0051] HDPE resin 60Kg

[0052] Linear Low Density Polyethylene Resin 40Kg

[0053] Carbon black 2.65Kg

[0054] Flame retardant 53Kg

[0055] Lubricant 4.8Kg

[0056]Antioxidant 1.4Kg

[0057] Antibacterial agent 1.6Kg

[0058] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com