Wide-spectrum white-light LED

A light-emitting diode, white light technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of narrow width, poor color rendering, narrow emission spectrum, etc., and achieve the effect of expanding width, changing color temperature, and improving color rendering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

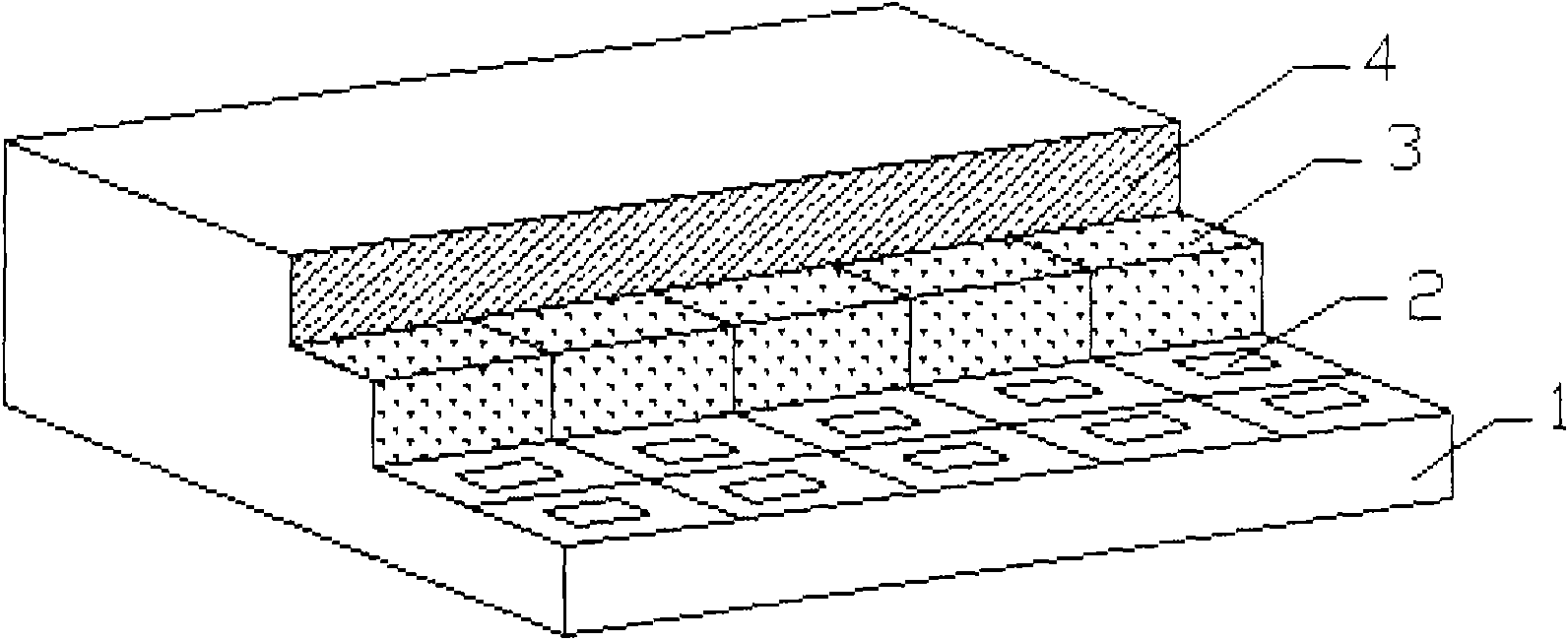

[0026] Using the luminescence of the GAN-based blue LED chip array layer 2 with the same luminescent color and different wavelengths as the basic light source, a part of the blue light emitted by the GAN-based blue LED with a wavelength of 455nm to 470nm is used to excite the phosphor, so that the phosphor emits yellow-green The other part of the light is emitted through the phosphor coating array layer 3 and mixed to form white light, that is, the mechanism of white light = blue + yellow, mixed to produce broad-spectrum white light:

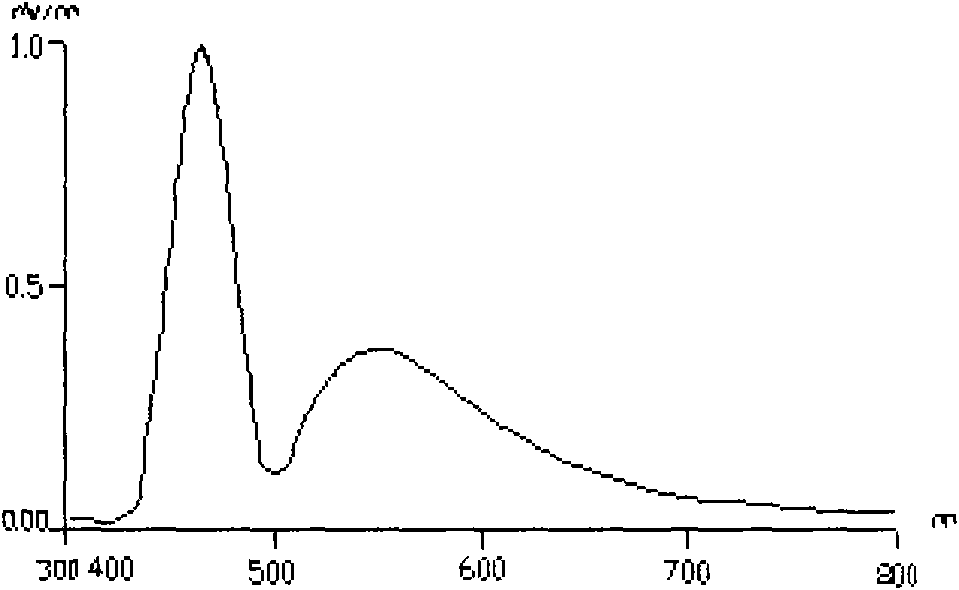

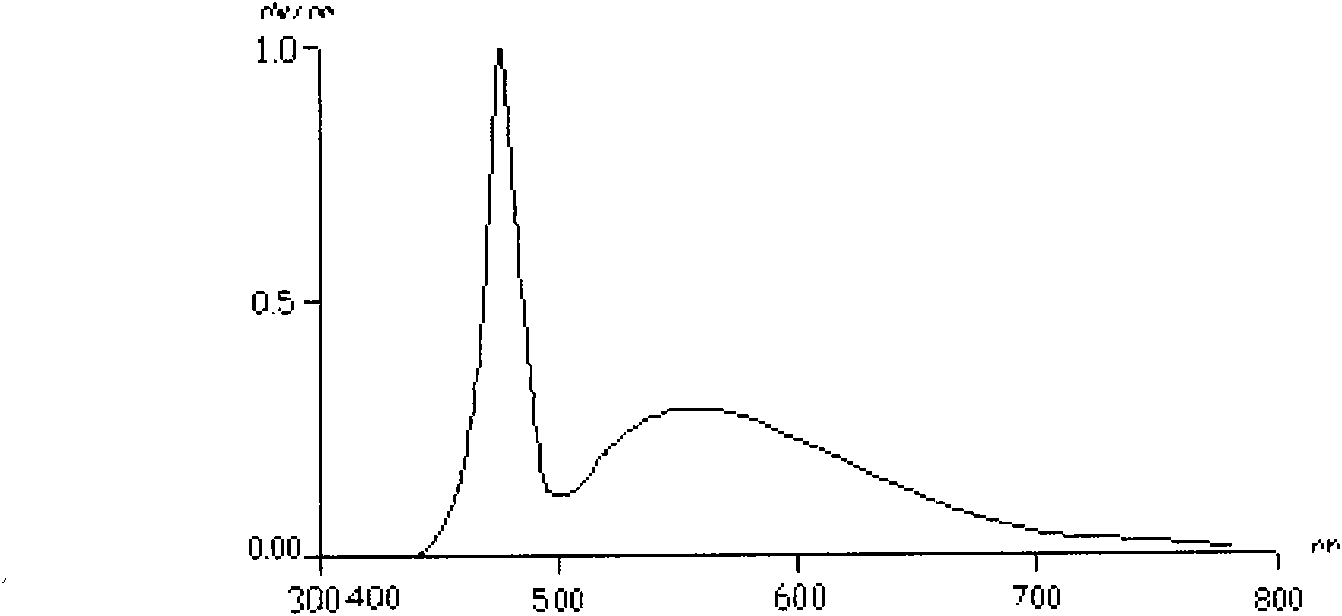

[0027] In order to make the chip arrays of different wavelengths match the excitation phosphor array, first use the phosphor comparator to select the corresponding matching phosphor. The matching result is that the 455nm of the blue light chip should match the 550nm phosphor, and the performance diagram of the white light-emitting diode produced in this way Such as figure 2 , use a spectrum tester to test the color rendering index (Ra image 3 ,...

Embodiment 2

[0031] According to the method of Example 1, in figure 1In the structure, a 455nm array of blue light chips is distributed around the metal or ceramic substrate 1, covering the 550nm phosphor coating array, and then a 470nm array of blue light chips is distributed, covering the 580nm phosphor coating array, so that two main blue light peaks and a 580nm phosphor coating array can be obtained. Two phosphor powder main peaks, and then use a red light chip 620nm array in the center of the metal or ceramic substrate 1 to display a red light main wave peak corresponding to the coating without phosphor powder. After solid crystal, bonding, and transparent material mixed light package 4 Mixed light packaging and other process steps are packaged together as a whole, so that the chip array layer 2 formed by the three chip light source peaks and the phosphor powder coating array layer 3 formed by the two phosphor powder peaks perform light mixing to complement the expansion of the red lig...

Embodiment 3

[0034] According to the method of Example 1, in figure 1 In the structure, a chip array layer 2 with a light-emitting wavelength of 430-480 nm is fixed on a metal or ceramic substrate 1, and then the array layer 3 is coated with red phosphor powder and yellow-green phosphor layer respectively in two layers, and then mixed with transparent materials. The optical package body 4 mixes colors to form white light. In the manufacturing process, some products have greenish or reddish chromatic aberration, and a layer of red phosphor or yellow-green phosphor can be applied as a correction according to the bias of the chromatic aberration to overcome the redness. The disadvantage of the uneven coating of fluorescent powder and green fluorescent powder is that the color of the LED lamp is not uniform due to the different specific gravity of the powder particles. In this implementation method, the specific gravity of each particle in the LED yellow-green fluorescent powder layer is approx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com